Hepworth Plastic Pipe Fittings - PPR Pipe Fitting for Hot or Cold Water Brass Ball Valve High Class Quality Standard from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Products

Place of Origin: Henan, China (Mainland)

Model Number: PE100

Material: PE

Specification: DN 20-mm~DN1200mm

Length: According to customer requirement

Thickness: SDR11/13.6/17

Standard: ISO

Color: many colors

Product name: Plastic Pipe

Application: house and garden

Usage: Family Decoration Industry

Certification: ISO Certificate

Feature: Lightweight

Size: Customized Size

Type: Round Pipe

Name: HDPE Plastic Pipe

Connection: Butt Fusion

Size

Product name | Size | Weight | Pack |

Equal tee

| (Gram/m) | (m/pack) | |

T16 | 12.5 | 1300 | |

T20 | 19.4 | 800 | |

T25 | 30.5 | 450 | |

T32 | 48.2 | 260 | |

T40 | 90.8 | 150 | |

T50 | 142.5 | 106 | |

T63 | 275.3 | 54 | |

T75 | 515.0 | 30 | |

T90 | 712.0 | 18 | |

T110 | 1082.0 | 12 | |

T125 | 1544.0 | 8 | |

T160 | 2531.0 | 4 |

Specification

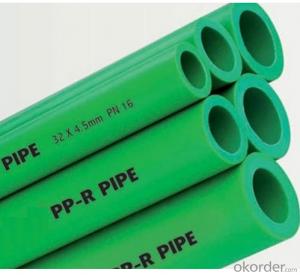

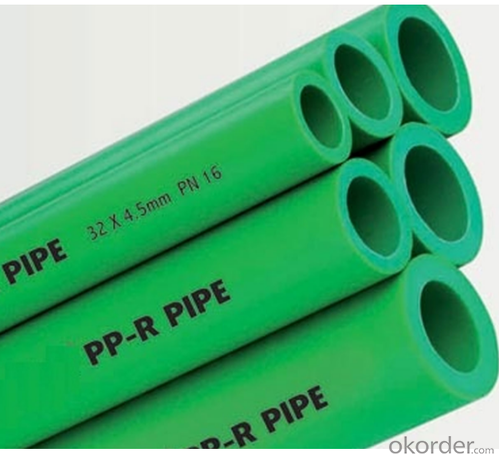

1.Material: | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | L/C, T/T, D/P,D/A |

Products Show

Product Advantages

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving.

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden

installation

9) Recyclable, environment-friendly, accords with GBM standards

FAQ

Q1: How Can I Get a Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C,D/A,D/P

- Q: How do plastic pipe fittings compare to fiberglass fittings?

- Plastic pipe fittings are generally more affordable and widely available compared to fiberglass fittings. However, fiberglass fittings are known for their superior strength, durability, and resistance to corrosion, making them suitable for high-pressure and corrosive applications. Additionally, fiberglass fittings offer better thermal and electrical insulation properties. Ultimately, the choice between plastic and fiberglass fittings depends on the specific requirements of the project and the desired level of performance.

- Q: Are plastic pipe fittings prone to leaks?

- Plastic pipe fittings are generally less prone to leaks compared to other materials such as metal or rubber fittings. However, just like any other fittings, the risk of leaks can still exist if they are not installed properly or used beyond their recommended limits. Regular inspection and maintenance are crucial to ensure a leak-free plumbing system.

- Q: What are the common applications for plastic pipe fittings?

- Plastic pipe fittings are commonly used in various applications such as plumbing systems, irrigation systems, water supply networks, and wastewater management. They are also employed in industries like agriculture, construction, and manufacturing, where they play a crucial role in conveying fluids and gases efficiently and securely. Additionally, plastic pipe fittings are often used in residential and commercial buildings for connecting and directing water, gas, and other liquids to appliances and fixtures.

- Q: Can plastic pipe fittings be used for hydronic heating systems?

- Yes, plastic pipe fittings can be used for hydronic heating systems. Plastic fittings are commonly used due to their durability, resistance to corrosion, and ease of installation. However, it is important to use fittings specifically designed for hydronic heating systems to ensure they can withstand the high temperatures and pressures involved.

- Q: Can plastic pipe fittings be used for conveying food products?

- No, plastic pipe fittings should not be used for conveying food products. It is recommended to use food-grade materials such as stainless steel or food-grade plastic fittings that are specifically designed and approved for contact with food. Plastic pipe fittings may contain chemicals or additives that could leach into the food, posing a potential health risk.

- Q: How do you connect plastic pipe fittings?

- Plastic pipe fittings can be connected by using solvent cement or by using compression fittings. Solvent cement involves applying a special glue to the pipe and fitting, which creates a chemical reaction that fuses them together. Compression fittings, on the other hand, require tightening a nut over a compression ring to create a watertight seal. Both methods are effective for connecting plastic pipe fittings, and the choice depends on the specific application and personal preference.

- Q: Can plastic pipe fittings be used for water supply in remote areas?

- Yes, plastic pipe fittings can be used for water supply in remote areas. They are lightweight, durable, and resistant to corrosion, making them suitable for long-distance transportation. Additionally, plastic fittings are easy to install and maintain, which is beneficial in remote locations where resources may be limited.

- Q: Are plastic pipe fittings suitable for use in food processing plants?

- No, plastic pipe fittings are not suitable for use in food processing plants as they can leach harmful chemicals into the food, posing a health risk. Stainless steel or other food-grade materials are recommended for such applications.

- Q: Can plastic pipe fittings be used for agricultural applications?

- Yes, plastic pipe fittings can be used for agricultural applications. They are often used in irrigation systems, water supply networks, and for various types of fluid transfer in agricultural settings. Plastic fittings are lightweight, durable, and resistant to corrosion, making them suitable for agricultural use. Additionally, they are relatively low-cost and easy to install, making them a popular choice for agricultural applications.

- Q: Are plastic pipe fittings resistant to scaling?

- Yes, plastic pipe fittings are generally resistant to scaling.

Send your message to us

Hepworth Plastic Pipe Fittings - PPR Pipe Fitting for Hot or Cold Water Brass Ball Valve High Class Quality Standard from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords