HD Metal Board, HD Aluminium Panel, Sublimation Aluminium Sheet, Sublimation Blanks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

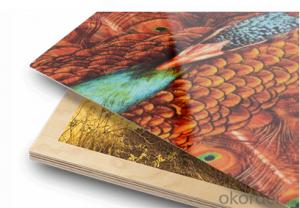

Sublimation Coated Aluminium Sheet

Sublimation aluminium sheet is manufactured specifically for sublimation printing

The hard surface coating on this aluminium is designed for improving image retention

Suggested heat transfer parameter: 200 ℃ and 40 seconds

Safe packaging and film for protection

High quality coating for sublimation and high definition

You can print any logo or pictures on it

Name of the product: Sublimation Coated Aluminium Sheet

Thickness: 0.45mm,0.55mm, other sizes as your customized

Size: 610*305mm,300*600mm,400*600mm,600*1200mm

Surface finish: Glossy, Matte, Satin, Pure,Pearlized,Brushed,Satin etc

Color: White,Silver,Gold,Cooper,Champange

Protection Film: PE,PVDF,PEVE,UV

Packaging: Seaworthy wooden pallet, wooden case or upon your request

Packaging & Delivery Packaging Details

Seaworthy wooden pallet, wooden case or upon your request

Delivery Detail

15~30 days after deposite

Weight of Packaging

1000 pics per pallet,Around 800 kg

What is WunderBoard HD metal prints?

Wunderboard is high-definition sublimation aluminum:

- Material: Aluminum

- Thickness: 1.14mm (0.045”)

- Biggest size: 1.2x1.2m (different/custom sizes are available)

- Finish: Glossy white

- Coating: 4 layers

--Water-proof, scratch-resistant and anti-UV.

Our advantage such as:

-Similar quality as as the top brand in USA(CHROMALUXE)

-Competitive price (much lower than others competitors)

-Cash Rebate policy and complete supports for distributors

These products are OK:

Sublimation Blanks

Heat press machine

DTG&UV pintor

The free samples are available, we're pleased to offer you some for testing.

Until now we stay strong connections with the regular market of Europe, Middle East, South America, Africa and etc. If you want to know us more

- Q: What is the printing plate roll made of? What are the materials?

- There are several manufacturers in this field in china. Distribution in Chengdu, Yunnan, Shanghai, Shenzhen and other places, layman recommended that you visit the site. The quality of the machine is better than the three.

- Q: Can you tell me how to make a good print?

- Control version dirty1, the printer will wipe the glass clean; remove the dust on the original manuscript, repair the defect on the original scratch; return the unqualified original, re production. For printing plate exposure caused by insufficient dirt, if dirt is not too serious, can supplement exposure using the diffusion sheet to move the position of the light exposure; can also improve the concentration of the developer, another developer.2, check the developering temperature and development time, and adjust to the corresponding standard; adjust the developer according to the formula given by manufacturer, update the developer; developing layout to fully clean water, the use of high-quality sponge layout; maintenance of automatic developing machine.3, in addition to dirty operation should be careful, apply brush to fill in except dirty liquid, except dirty, in addition to dirty time should be kept in 20, 30 seconds; in addition to dirty liquid use should be covered tightly; layout except dirty treatment, should use water fully flush.

- Q: How do I change the colors of printing plates into monochrome?

- The printing process can also rotate the gray scale and only one color after the gray shift

- Q: Printing and make-up are the same

- Of course, not the same, which is similar to the layout design, to provide customers with text and pictures in accordance with the requirements of CorelDRAW software into vector customer requirements of the customer and board results, is the customer good layout content according to the size of a spell on the page.

- Q: How to repair the printed circuit? How can the printed circuit board be broken by 1cm?

- Printed circuit board, also known as printed circuit board, printed circuit board, is an electronic component of the electrical components connected. The printed circuit board, in accordance with the plate making method in the printing industry, first draws an electronic circuit diagram, and forms a conducting circuit on the insulating board.

- Q: Can I make a screen print?

- With these things, you can start the screen:1. mesh taut stick or nail on the prepared screen frame.2., the photosensitive coating evenly coated in the first step on the preparation of the screen (pay attention to coating evenly, smooth, no light transmission phenomenon)Then blow dry with a hair dryer3. and the back of a film patch ready in the above screen (attached to the outside) and then illuminated with a light source (can be the light of the sun, can also be a fluorescent lamp, also can be the hospital that ultraviolet tube for Deng can also, is a special version of the light (note must be the same network version film tightly, not have the gap between)

- Q: How do I reduce the layout of carton printing?

- In order to ensure the accuracy of typesetting, drawing the reference line is the basis of typesetting, which should be paid more attention to. If the standard drawing is not good, it will lead to the deviation of the work later, and then there will be the problem of layout position or overprinter. There are two main line, one is the vertical centerline of the hanging plate, the base line must be from the upper edge of the page has been drawn to the lower edge; another is the zero line of horizontal direction, namely the corrugated boxes cover line distance from the edge of the standard version of the film hanging.

- Q: What does the PS version of the print mean?

- The PS version is an aluminum version for printing, specifically a PS version of the film!

- Q: What does the print edition mean?

- The printing plate can be divided into four categories: relief plate, intaglio plate, lithographic plate and orifice plate:LetterpressRelief printing plate is the graphic part, higher than the blank part.gravureAn intaglio is a graphic part of a printing plate, less than a blank part.

- Q: Why is the screen printing broken?

- In the printing process, the version of film broke, mainly the process of plate making technical problems:1, the printing time is short, plastic film light curing is not sufficient, resulting in screen printing.2, before the plate, the mesh did not make degreasing treatment, resulting in photosensitive adhesive on the screen is not firmly, it is easy to break gel.

Send your message to us

HD Metal Board, HD Aluminium Panel, Sublimation Aluminium Sheet, Sublimation Blanks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords