HD Metal Board, HD Aluminium Board, Sublimation Panel Aluminium Sheet, Sublimation Blanks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Sublimation Coated Aluminium Sheet

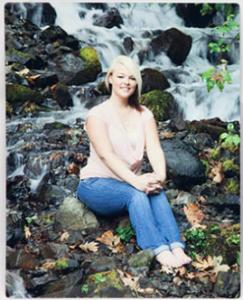

Sublimation aluminium sheet is manufactured specifically for sublimation printing

The hard surface coating on this aluminium is designed for improving image retention

Suggested heat transfer parameter: 200 ℃ and 40 seconds

Safe packaging and film for protection

High quality coating for sublimation and high definition

You can print any logo or pictures on it

Name of the product: Sublimation Coated Aluminium Sheet

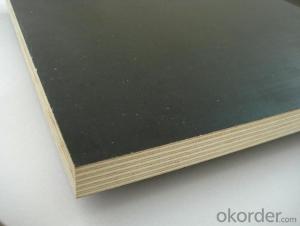

Thickness: 0.45mm,0.55mm, other sizes as your customized

Size: 610*305mm,300*600mm,400*600mm,600*1200mm

Surface finish: Glossy, Matte, Satin, Pure,Pearlized,Brushed,Satin etc

Color: White,Silver,Gold,Cooper,Champange

Protection Film: PE,PVDF,PEVE,UV

Packaging: Seaworthy wooden pallet, wooden case or upon your request

Packaging & Delivery Packaging Details

Seaworthy wooden pallet, wooden case or upon your request

Delivery Detail

15~30 days after deposite

Weight of Packaging

1000 pics per pallet,Around 800 kg

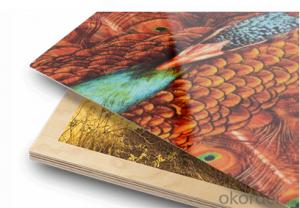

What is WunderBoard HD metal prints?

Wunderboard is high-definition sublimation aluminum:

- Material: Aluminum

- Thickness: 1.14mm (0.045”)

- Biggest size: 1.2x1.2m (different/custom sizes are available)

- Finish: Glossy white

- Coating: 4 layers

--Water-proof, scratch-resistant and anti-UV.

Our advantage such as:

-Similar quality as as the top brand in USA(CHROMALUXE)

-Competitive price (much lower than others competitors)

-Cash Rebate policy and complete supports for distributors

These Aluminum Panels can provide for many sizes and different color. It can suitable in many occasion, like company logo screen, show backdrop, home use, some gift use etc. We can also provide the heat press machine for transferring

The free samples are available, we're pleased to offer you some for testing.

- Q: How to make the screen print surface smooth?

- Finish drying / curing, then apply a layer of solvent based paint on the panel. Before drying, vacuum the part with the pattern on the back to make it clear, without vacuum

- Q: How do I change the colors of printing plates into monochrome?

- See what kind of situation, if in prepress, that is, with software modifications can be. If added to the process, the color is converted to grayscale in the process

- Q: Printing and make-up are the same

- Typography is sent to the customer file, can print that is the imposition of the same material file spell in a version according to the law, out of print

- Q: How to repair the printed circuit? How can the printed circuit board be broken by 1cm?

- After cleaning, connect the position of the connection by wire.

- Q: The difference between the 60 and 100 lines of the printing roller

- The characteristics compared with the traditional gravure, offset printing and convex printing flexo printing, flexo printing mode has its own distinctive characteristics: 1, less investment, quick effect, high efficiency. Flexo presses are much cheaper in comparison to gravure presses and offset presses of the same colour set. In addition, flexo printing presses, die-cutting, glazing and other processes in one, multi-channel processes can be completed at one time, without further purchase of the corresponding post-processing equipment, has a high return on investment. 2, the equipment structure is relatively simple, so the operation is relatively simple and convenient. 3, high production efficiency. Flexo printing is used to reel material, not only can realize the printing of double-sided printing materials, but also to complete the line of glazing (or film), bronzing, die-cutting, waste rejection, volume and other work. The production cycle is greatly shortened, the manpower, material and financial resources are saved, the production cost is lowered, and the economic benefit is improved. 4, the printing materials range is relatively wide, such as paper, plastic film, aluminum foil, self-adhesive paper and so on. 5. The quality of printed matter is good, the printing accuracy can reach 150 lines / inches, and the printed material is rich in layers, bright in color and good in visual effect, especially suitable for the requirements of packaging and printing. 6, the use of new water-based ink and solvent based ink, non-toxic, pollution-free, fully meet the requirements of green environmental protection, but also to meet the requirements of food packaging.

- Q: How can I place the printing rollers in the most convenient place?

- With two vertical hook welding iron roller in the warehouse at the corner of wall can be guaranteed and two pending such local quality of roller.

- Q: What's the color of the print edition?

- In general, photographs taken by color photography to reflect the rich colors of nature, facial expressions, paintings of artists, or other pictures containing many different colors. For technical requirements or economic considerations, a picture must be scanned by an electronic color scanner or a color desktop system. The process is then reproduced by four-color printing.The deployment of spot color printing ink to the subtractive mixing principle of pigment color, the color brightness is low, high degree of saturation. The solid ink evenly using spot color printing. A change in color, which is sensitive to changes in color, decreases when appropriate ink is applied and the thickness of the ink layer is thicker. It is easier to get ink evenly, thick printing effect.A four colour block. As a result of the composition of the color of the color, mostly by a certain proportion of dot composition. When printing dots, the thickness of the ink layer must be strictly controlled. It is easy to produce large chromatic aberration due to the change of the thickness of ink layer.

- Q: How do I reduce the layout of carton printing?

- When publishing hang article version of paste must and hang banpian base edge alignment. At present, the domestic corrugated carton factory commonly used adhesive tape in hang banpian hang article version of traditional fixed process, this print version in use and after a long time suspension preservation process, due to the relatively hang article version force, often hang article version shift phenomenon, especially in the year second quarter and third in the hot and humid quarter especially. In order to change this phenomenon, part of the corrugated carton enterprise began to use the cold welding technology, will hang banpian hang version with joint material fusion, cooling, the hang article version one-time firmly welding die in banpian hang, ensure the hang article version orientation stability. At the same time, in order to prevent hang banpian near the ends strip tear in force, and generally increase fiber tape for reinforcement.

- Q: What does the print edition mean?

- OffsetA lithographic plate is a graphic part and a blank part of a printing plate, basically in the same plane, and has the characteristics that the printing part is lipophilic and the blank part is hydrophilic.stencil printA plate is a picture of a plate, consisting of holes or meshes of different sizes or sizes.

- Q: Why is the screen printing broken?

- There are two kinds of broken screen:1, silk broken2, the film version brokenYou said the screen broken, probably refers to the latter, that is, broken version of film.

Send your message to us

HD Metal Board, HD Aluminium Board, Sublimation Panel Aluminium Sheet, Sublimation Blanks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords