Suspended Gypsum Ceiling Board - Fire Rated Access Panel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

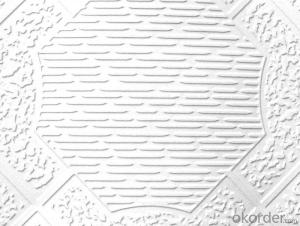

Plasterboard is made of high-grade environmental protective gypsum raw material, no harming to human body, and it has some performances: (such as environmental protection, fire-proof, moisture-proof, light and high intensity).

Product Applications:

1.Ceilings and walls of building, hotels, shopping malls, hospital, school, office, house and etc indoor decoration

2.Central air conditioning system

3.Access ductwork or pipe work above the light fixtures , vents , fire fighting pipeline, bathroom pipeline, etc.

Product Advantages:

1.Thermal insulation

2.Fire-resistant performance for fire-proof plasterboard

3.Water-resistant performance for water-proof plasterboard

4.Easy installation (it can be easily sawed,planed,holed and sticked)

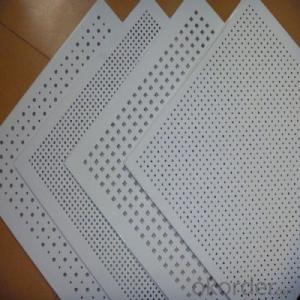

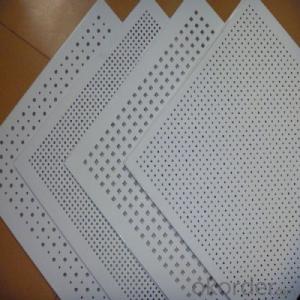

5.Special respiratory function (it has a great mass of ting holes and its function of moisture-adsorbing and moisture-dismissing)

Main Product Features:

1 For installation in fire rated vertical wall or horizontal ceiling.

2 Fire rating: 1-1/2 hour B label for walls (maximum temperature rise after 30 minutes 250°F/139°C, after 60 minutes 450°F/250°C), and Warnock Hersey label for ceilings 1 hour combustible rating and 3 hour non-combustible rating.

3 Material: 16 gauge (1.52mm) steel frame and 20 gauge(0.912mm) satin coated steel door panel

4 Insulation: 2” thick fire rated mineral wool

5 Hinge: flush continuous piano hinge

6 Lock: self-latching flush key or ring knurled knob operated slam latch, with automatic closer and interior latch release mechanism.

7 Interior panel release and automatic panel closer are standard on all doors

8 Finish: high quality grey powder coating.

9 Packing:1 piece per box.

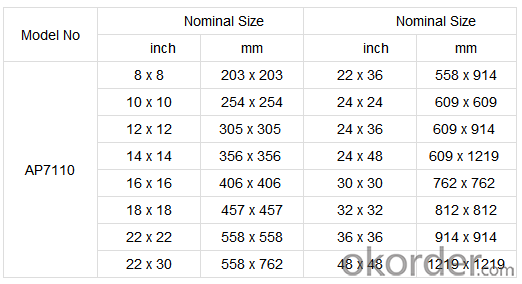

Product Specifications:

FAQ:

1. What kind of certificate do you have?

ISO9001, ISO14001, CE, SONCAP, VOI(CO), CARB, FSC, CE

2. What color can you produce?

You can choose the design you want

3. How about the delivery time?

20-25 days after receiving prepayment or L/C

For the samples, it will be prepared ASAP.

4. What's the MOQ and Payment Terms?

Minimum Ordering Quantity: 2X20ft Container

Payment Terms: T/T or L/C at sight

Images:

- Q: Do you have to do gypsum board on top of the ceiling?

- Do not do gypsum board can also be posted, but the wall to do grass-roots treatment,

- Q: Gypsum board ceiling wire how to do

- Home decoration ceiling is a common part of home improvement. The ceiling is different according to the material of the decorative plate, and the classification is not the same. Ceiling decoration materials is the main basis for distinguishing the name of the ceiling, mainly: light steel keel gypsum board ceiling, gypsum board ceiling, mineral wool board ceiling, plywood ceiling, profiled long strip of aluminum slab ceiling, Glass ceiling, aluminum honeycomb perforation sound-absorbing panels such as ceiling.

- Q: Because I want to change part of the circuit Want to split some living room ceiling The original installed gypsum board ceiling can be demolished? Is it possible to replace it later?

- Can be demolished, after the demolition must be re-finished again

- Q: My interior decoration of a company about 170 square meters, gypsum board ceiling what materials are needed? Please master the details.

- If it is a straight line hanging shed, need the main keel card or hanging (hanging keel with 38 main bone plus hook), 50 bone, gypsum board, self-tapping nail, milk white plastic, hanging wire diameter 6mm or diameter 8mm, hanging bar Specialized expansion.

- Q: What is the down ceiling

- The ceiling is mostly used for central air conditioning units, because the central air conditioning thickness of more than 35cm or so, down the ceiling can increase the sense of hierarchy, higher requirements on the room, the general requirements of more than 2.7m. Commonly used materials are light steel keel and gypsum board.

- Q: To prevent gypsum board ceiling split in addition to paste kraft paper and cloth what good way?

- 1, keel system check is good, large area should be arch. 10 meters long, from arch 1-2cm; 2, more than 10 meters long ceiling should be set expansion joints; 3, gypsum board fixed check again to see if there is no fixed fixed; 4, with gypsum-based powder approved in the gypsum board than with the old powder putty batch on the gypsum board sinking much less impact; 5, with high-quality gypsum board caulking paste to do the joint treatment, the proposed Lafarge, Pratt, Knauf, Long card and other brands.

- Q: Gypsum board ceiling practice

- (1) Check the installation of the roof concealed works, such as air conditioning system, fire spray, smoke system, supply, power distribution system, background music and other lines are installed in place and the hidden acceptance. (2) according to the design requirements around the leveling, the middle of the shed from the conventional arch (3) the boom can be used to cast the board when the embedded parts or reserved hook connection, can also be used offset screws, fixed in the upstairs after drilling (4) boom keel spacing by the manufacturers to provide a reasonable distribution of materials, keel connection to be fixed after the line leveling. (5) all metal parts such as no electroplating, must first brush rust oil twice (6) the edge of the gypsum board planed into a chamfer, and then with a tapping screw and keel compound, tighten. (7) gypsum board docking slit 2-3mm, and chamfer, covered with caulking putty, the joint belt buried in the putty, and putty to the gypsum board chamfer filled, after the plate with a flat plate leveling The

- Q: The distance between the curtains of the Roman rod and the ceiling or gypsum line should be appropriate?

- The top hole is 6 cm distance, the premise is that your curtains are done to the floor

- Q: what is the cost for gypsum false ceiling in CANADA?

- get a professional in to get you a quote

- Q: Wood keel and gypsum board + auxiliary material = 45 yuan or so. Oh `` `` Housing decoration prices: housing prices of 10% to 20%. The main material to buy: the reasonable cost of material distribution ratio is: bathroom and kitchenrooms accounted for 45%, hall accounted for 35%, bedroom accounted for 20%. Cost per square meter: different decoration standard costs vary widely, and some square meters is the price of several times or several times the price.

- Gypsum board ceiling of the reasonable price

Send your message to us

Suspended Gypsum Ceiling Board - Fire Rated Access Panel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords