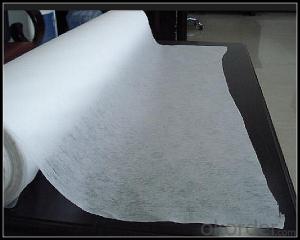

10 Oz Non Woven Geotextile Fabric for Dam Construction by Good Woven Geotextile Fabrics Companies

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 10000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

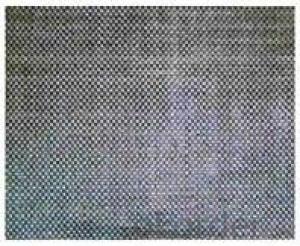

WOVEN GEOTEXTILES

1 High Performance

2 High Tensile Modulus

3 Monofilament

4 lit Film

Woven geotextiles consist of monofilament, multifilament, slit-film and/or fibrillated slit-film yarns - often in Woven geotextiles Image combinations - that are woven into a geotextile on conventional textile weaving machinery using a wide variety of traditional, as well as proprietary, weaving patterns. The variations are many and most have a direct influence on the physical, mechanical and hydraulic properties of the fabric.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

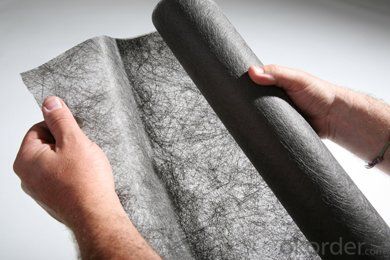

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

- Q: How do geotextiles help with filtration?

- Geotextiles help with filtration by providing a barrier that allows water to pass through while retaining soil particles and other contaminants, preventing their migration.

- Q: Can geotextiles be used in landscaping projects?

- Yes, geotextiles can be used in landscaping projects. Geotextiles are often used as an effective way to control erosion, stabilize soil, and separate different layers of soil or aggregates in landscaping applications. They can be used for retaining walls, slope stabilization, weed control, and drainage systems, among other purposes.

- Q: Is the polypropylene composite geotextile and the polyethylene composite geomembrane the same?

- Geotextiles and geomembranes are not the same, but they complement each other to meet the engineering requirements. First introduced under the geotextile: geotextile is the state for civil engineering in the construction of a new type of construction materials, by filament or short fiber through different equipment and process shop into a mesh, and then after acupuncture and other processes to different Fibers are intertwined with each other, tangent to the fabric to make the fabric normal, so that the fabric is soft, plump, thick, stiff, to meet the different thickness to meet the requirements, according to the length of silk is divided into filament non-woven geotextile or short wire Non-woven geotextile, filament tensile strength higher than the short wire. Fibrous soft with a certain tear resistance. The main role is: filter, filter, reinforcement role. Specifications from 100 grams per square meter to 800 grams per square meter. The main material for the polyester fiber, with excellent permeability, filtration, durability deformation adaptability, and has a good flat drainage capacity (see below) Geomembrane to plastic film as anti-seepage substrate, and non-woven composite Made of geotextile impermeable material can be divided into two cloth a film, a cloth a film, its impermeability depends mainly on the plastic film impermeability. The geomembrane is a waterproof barrier material with the polymer of the polymer chemical material as the basic raw material. The proportion of small, strong extension, high adaptability to adapt to deformation, corrosion resistance, low temperature, good frost resistance. (See below)

- Q: How do geotextiles help in subsurface drainage?

- Geotextiles help in subsurface drainage by acting as a filter and separation layer between the soil and the drainage material. They prevent the soil particles from clogging the drainage system while allowing water to pass through, promoting efficient water flow and preventing waterlogging.

- Q: How do geotextiles help with siltation control in construction sites?

- Geotextiles help with siltation control in construction sites by acting as a barrier, preventing sediment from washing away and polluting nearby water bodies. They retain soil particles while allowing water to pass through, thus reducing erosion and maintaining the stability of the construction site.

- Q: What are the different geotextile permeability testing methods?

- Some of the different geotextile permeability testing methods include the constant head method, falling head method, and the variable head method. These methods involve measuring the flow of water through the geotextile under different conditions to determine its permeability.

- Q: What are the considerations for geotextile selection in landfill projects?

- When selecting geotextiles for landfill projects, several considerations must be taken into account. These include the desired function of the geotextile, such as separation, filtration, or drainage. The physical properties of the geotextile, such as tensile strength, puncture resistance, and thickness, are also important factors to consider. Additionally, the site conditions, such as soil type, water table, and potential for chemical exposure, should be evaluated to ensure the geotextile's compatibility. Lastly, the long-term durability and cost-effectiveness of the geotextile should be considered to ensure its suitability for the landfill project.

- Q: Google for a long time only geotextile ads! The The Do not know geotextile, drainage board such materials, in what kind of shop which has to sell? Because the building materials market to a circle, people did not sell this thing more

- I professional production of drainage board, geotextile, geomembrane and other products, wish smooth

- Q: Construction Technology of Seepage Control of Geotextile for Landscape Water System

- Laying HDPE geomembrane should try to weld at least, in ensuring the quality of the premise, as far as possible to save raw materials. But also easy to ensure quality. The lap width of the joint between the membrane and the membrane is generally not less than 10 cm, usually in the direction of the weld arrangement parallel to the maximum slope, that is, along the slope direction. Geomembrane thickness of not less than 0.25mm, too thin may produce pores, and easy to damage in the construction and reduce the anti-seepage effect. Geomembrane construction, in particular, should pay attention to laying should not be too tight, not wrinkled, stitching to be strong. Should be strictly in accordance with technical specifications construction, the good preparation, laying, splicing, inspection and backfill, such as five quality off. I specialize in production and construction

Send your message to us

10 Oz Non Woven Geotextile Fabric for Dam Construction by Good Woven Geotextile Fabrics Companies

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 10000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords