Slope Reinforcement Geogrids - Good Toughness Polyethylene Geogrid High Strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

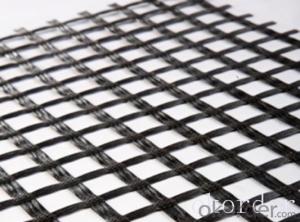

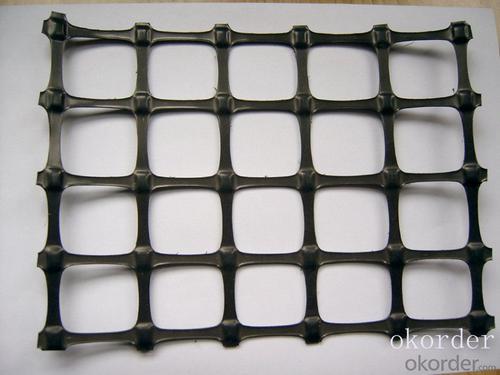

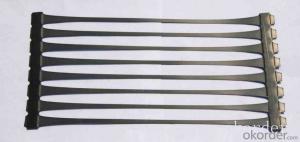

The outlook of the biaxial geogrid is net work structure like a square. It uses polyester as its raw material and is made of high molecular polymer through extrusion, formed and punched before longitudinally and laterally stretched. This kind of material has a high tensile longitudinally and horizontally, which can be used to reinforce the basement.

Geogrids form a distinct category of geosynthetics designed for reinforcement.

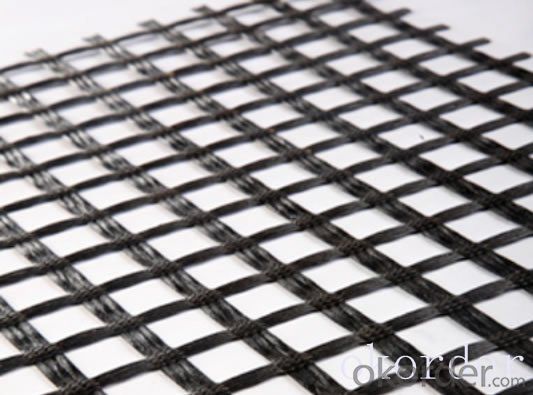

Fiberglass Geogrid with CE Certificate

We can produce fiberglass geogrid with tensile strength 30x30kn--300x300kn/m. mesh size can be 25.4x25.4mm or 12.7x12.7m ,50x50mm.

Type:

Geogrids

Material:

Fiberglass

Coating:

asphalt

feature:

High flexibility and large range

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

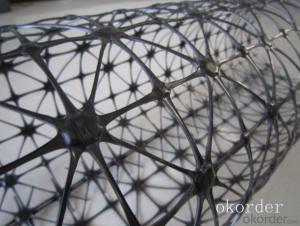

A: Yes, please check the pictures:

- Q: Can geogrids be used in riverbank protection projects?

- Yes, geogrids can be used in riverbank protection projects. Geogrids are effective in stabilizing soil and preventing erosion, making them suitable for reinforcing riverbanks and providing structural support. They can help to mitigate the effects of water flow and protect the riverbank from further damage.

- Q: How much is the double polypropylene plastic geogrid outsourcing testing fee?

- Special material testing cycle is not the same, some 3 days, some need to soak, need to detect acid-base, a lot of a lot, and I hope to help you, please adopt,

- Q: Can geogrids be used in underground mining operations?

- Yes, geogrids can be used in underground mining operations. Geogrids are a type of geosynthetic material that provide reinforcement and stability to soil or rock structures. In underground mining, geogrids can be used for ground support and stabilization, preventing collapses and enhancing safety. They can also be used for reinforcing roadways, tunnels, and other underground structures, improving their load-bearing capacity and longevity.

- Q: How do geogrids improve the stability of channel linings?

- Geogrids improve the stability of channel linings by enhancing soil reinforcement and preventing erosion. They act as a strong and flexible reinforcement material that helps distribute the loads and stresses applied to the channel lining. By interlocking with the surrounding soil, geogrids increase the overall tensile strength and shear resistance of the structure, preventing it from shifting or collapsing. Additionally, geogrids provide a barrier against erosion by stabilizing the soil particles and preventing them from being washed away by flowing water, thus maintaining the integrity of the channel lining.

- Q: Can geogrids be used in temporary retaining structures?

- Yes, geogrids can be used in temporary retaining structures. Geogrids are commonly used to reinforce soil and provide stability in retaining walls and structures. They are versatile and can be used in both permanent and temporary applications, making them suitable for various construction and engineering projects.

- Q: Are geogrids suitable for use in agricultural applications?

- Yes, geogrids are suitable for use in agricultural applications. They can be used to strengthen soil and improve stability, reducing erosion and preventing soil compaction. Additionally, geogrids can enhance the performance of agricultural structures such as retaining walls, embankments, and roadways, making them a valuable tool in agricultural engineering.

- Q: Can geogrids be used in soil erosion control for agriculture?

- Yes, geogrids can be used in soil erosion control for agriculture. Geogrids are commonly used to reinforce and stabilize soil, preventing erosion caused by water runoff or wind. They provide strength and stability to the soil, reducing the risk of erosion and preserving the integrity of agricultural land.

- Q: Can geogrids be used in temporary construction platforms?

- Yes, geogrids can be used in temporary construction platforms. Geogrids are commonly used in construction projects to reinforce soil and provide stability. They can be used as a cost-effective solution for temporary construction platforms by improving load-bearing capacity and preventing soil erosion.

- Q: What is the difference between polyethylene geogrid and uni directional high strength geogrid

- By stretching, the chain shaped molecules which are scattered in the original distribution are in a linear state, which improves the tensile strength and rigidity of the grid. Laying in the soil, through the mesh grille and soil interlock and interlock function, constitute an efficient stress transfer mechanism, so that local load can be quickly and effectively spread to a large area of soil, to reduce the local failure stress, to achieve the purpose of improving life. One

- Q: How do geogrids help in reducing construction material consumption?

- Geogrids help in reducing construction material consumption by providing reinforcement to the soil, allowing for the use of less material in the construction process. They increase the strength and stability of the soil, enabling the use of thinner layers of construction materials such as aggregates or concrete. This results in cost savings and reduced environmental impact due to the reduced use of materials.

Send your message to us

Slope Reinforcement Geogrids - Good Toughness Polyethylene Geogrid High Strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords