Glass Wool Pipe - 20kg/m3 China Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Glasswool Description:

Glasswool board is the unearthly sound absorbing and warm keeping material. It has been widely applied for heat insulation of house wall, compartment; temperature keeping of computer rooms, refrigerator; denoise of power plants and pump rooms; adjustment of Hi-fi etc.

This special cell structure means that the sheet doe’s not conduct heat. When you lay XPS boards as an underlay any heat from your room or floor will be reflected back towards the floor surface. As you will not be wasting heat through your floor you will utilize your energy in an effective manner and thereby lower your energy consumption and carbon footprint.

2. Main Features:

1. Excellent thermal insulation

2. High compressive strength of excellence

3. High-quality water-repellent, moisture resistance

4. Energy saving and environmental protection

5. Excellent heat preservation and insulation

3. Scope of application:

It is widely used for heat insulation and sound absorption in industrial workshops, Prefab houses, Portable cabins, warehouses, public facilities, exhibition centers, shopping malls, and a variety of indoor playgrounds, sports stadiums and etc

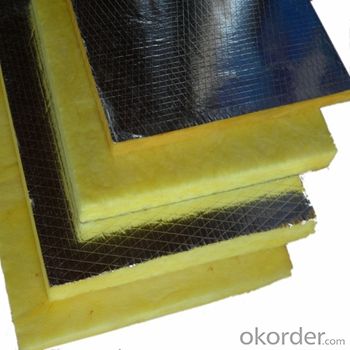

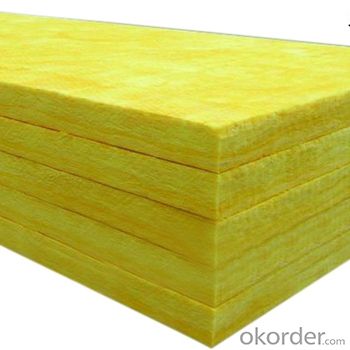

4. Glasswool Images

5. Glasswool Specification

density(kg/m3) | width(mm) | thickness(mm) | length(m) | packing/roll Vacuum package | |

10-48 | 1200 | 25-150 | 10-30m | 2roll | |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

6. FAQ

(1) How about your company?

A world class manufacturer & supplier of glasswool and is one of the large scale professional investment glasswool bases in China. Annually more than 1000 containers of glasswool are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

The user should take test and do trial application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served

- Q: Can glass wool be used for external wall insulation?

- Yes, glass wool belongs to the category of glass fiber, which is a kind of man-made inorganic fiber. With good thermal insulation and sound-absorbing properties. Currently the relatively good glas wool on the market is Huamei Senda.

- Q: Who know the construction technology of glass wool?

- I would like to give a brief introduction to the usage of glass wool as the thermal insulation for equipment. 1, Cleaning dust on the surface of equipment. 2, Using adhesive to glue the iron sheet of insulation nails (iron sheet of one square centimeter will be fed in the middle with a slightly harder iron wire of about 8 centimeters) on the surface of the device. Distribution density depends on the weight of glass wool. If insulated cotton is 1 m * 0.5 m, it merely needs to glue seven to eight pieces of iron sheet. When glue of iron sheet finished, the device is like a hedgehog. 3. Once insulation nails sticked firmly, it needs to affix to glass wool, fixing it with a piece of spare iron sheet with a hole in the middle of it (it is round and is a set with insulation nails), and then bend the redundant part of iron wire.

- Q: How to conduct thermal insulation construction of external wall glass wool?

- I would like to give a brief introduction to the usage of glass wool as the thermal insulation for equipment. 1, Cleaning dust on the surface of equipment. 2, Using adhesive to glue the iron sheet of insulation nails (iron sheet of one square centimeter will be fed in the middle with a slightly harder iron wire of about 8 centimeters) on the surface of the device. Distribution density depends on the weight of glass wool. If insulated cotton is 1 m * 0.5 m, it merely needs to glue seven to eight insulation nails. When glue of iron sheet finished, the device is like a hedgehog. 3. Once insulation nails sticked firmly, it needs to affix to glass wool, fixing it with a piece of spare iron sheet with a hole in the middle of it (it is round and is a set with insulation nails), and then bend the redundant part of iron wire. Wish it will help you. Thank you!

- Q: Now what is the latest color steel sandwich board? such as: Foam, stretches, glass wool

- Foam is the mainly material, now with the increase of rock wool, the rock wool can be fireproofing and sound absorption, it may also lay glass wool in the interior of color steel?plate and the function is sound absorption and thermal insulation.

- Q: What environmental pollutions will be created during the production of glass wool?

- It is quite dangerous. Glass wool is very small, such as phenol. If it gets into lungs,the health hazards in the exhaust gas are harmful. If it is on the skin, it will be atingle and itchy. During the production of glass wool, there will be formaldehydes and glass fiber dust.

- Q: Centrifugal glass wool board and flexible foam rubber insulation, which one is better?

- Glass wool for the steam pipe insulation. Rubber insulation for the air conditioning. They both can endure high temperature but are used in different fields.

- Q: What is the fire rating of fireproof sound-insulating glass wool board?

- Glass cotton can be made into board materials after the curing process, and can retain its insulation and sound absorbing properties at random temperatures.glass wool board is also known as sound insulation board/cotton, sound absorbing board, fireproof cotton, fillinf cotton for sandwich wall.it is high-quality insulation and fireproof materials for absorbing sound and reducing noise in architectural and industrial fields. It is also used for meeting room, audio-visual room, studio, auditorium, piano room, rehearsal rooms, gymnasium, computer rooms, theaters, television stations, radio stations, laboratories, studios, laboratories, recording studios, sound-absorbing in places like bars and KTV. 1. environmentally friendly, non-toxic 2. light and simple construction 3. strong shock resistance, long durability 4. strong insulation and low thermal conductivity 5.A level non-combustible material,strong fireproof property 6. It can absorb sound and reduce the noise.

- Q: What is the difference between Kun Nai glass?wool?board and rock wool?

- Hastelloy alloy has made remarkable breakthrough in 1960s. Before that corrosion hinders the development need to weld the alloy solution treatment HAZ corrosion resistance can lower the number of devices produced by welding must be applied engineering problems to provide solutions HastelloyC-276 case http://www.jyx66 /

- Q: How many types of centrifugal glass wool?

- It seems to be three to five varieties, I hope it is helpful to you.

- Q: What is the difference between high density glass wool board and stereoplasm rock wool board?

- Centrifugal glass wool uses glass as the main raw material. Glass mixed with a certain percentage of other materials should be fully melted in the glass furnace. The melted solution will flow out of bushing and enter into the centrifuge.In the high speed centrifuge, glass will be thrown into a glass thin stream. Under the effect of high temperature and high speed flame, glass thin stream is further stretched into fibers and sprayed with foggy adhesive. In the effect of negative pressure wind cotton webs, the fibre with resin adhesives falls on mesh belt, forming a homogeneous cotton blanket and then it is solidified in thermostat curing oven. After the shape of it is fixed, the glass wool will become predetermined products after cut and then be packed.The main raw material of rock wool products is fine basalt rock. The basalt rock is made into inorganic fiber after meited under high temperature and processed in the high-speed centrifugal device. Then the arrangement structure of the fibre is changed after it is add with special binder and dust laying oil and put in a special device. In the last step, the product is solidified and become a new lightweight thermal insulation material. Depending on the application, it can be processed into wool board, rock wool blanket and wool shell.Compared with rock wool, glass wool is of lower unit weight, less shot content, lower thermal conductivity, long service life and high tenacity fiber, rock wool. However, the maximum operating temperature of rock wool is about 600 degrees Celsius while the glass wool is only about 260 degrees Celsius.Glass woolwool is generally used in thermal insulation part less than 200 degrees Celsius and is mainly used for thermal insulation in general buildings or low temperature pipes. Rock wool is generally used at thermal insulation part with the temperature of 500 degrees Celsius and is mainly used for heat perservation of of high temperature heat pipes or electrical equipment.

Send your message to us

Glass Wool Pipe - 20kg/m3 China Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords