Glass Wool Al+Cpe One Layer Bubble Foam for Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. MPET with XPE One-Layer Bubble Foam for Insulation Description:

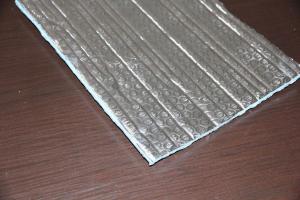

Reflective insulation material consists of one or two layers bubble or foam that are sandwiched between layers of 99.9% pure aluminum radiant barrier foil . This style can be used in a variety of applications because of its thin, lightweight properties. The bubble layers creates Maximum R value and Vapor barrier , the reflective foil on both sides allow it to reflect 97% of radiant heat away from a structure on the outside and back into a structure from the insides. This is why it works effectively in both hot and cold climates

2.Main Features of the MPET with XPE One-Layer Bubble Foam for Insulation:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

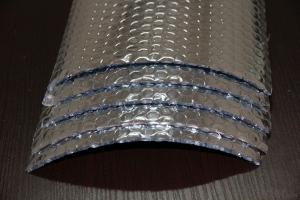

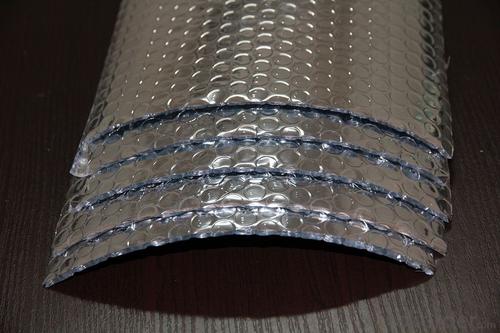

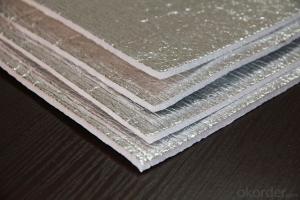

3. MPET with XPE One-Layer Bubble Foam for Insulation Images:

4. MPET with XPE One-Layer Bubble Foam for Insulation Specification:

PROPERTIES Test Data

Thinkness 3.5MM

Weight 256G/M2

Emissivity 0.03-0.04COEF.

Thermal conductivity 0.034W/MO

Apparent Density 120KG/M3

Reflectivity 96-97%

Water Vapour Transmission 0.013G/M2KPA

Corrosion Doesn't generate

Tensile strenght(MD) 16.98Mpa

Tensile strenght(TD) 16.5Mpa

AL+bubble +AL

AL +bubble /bubble +AL

AL+Bubble+ Foam+Bubble+AL

AL+Bubble+PE

AL+EPE +BUBBLE+AL

AL+XPE+Bubble +AL

Note : AL refer to Aluminum Foil,the structure and the surface color of AL can be changed as customer’s requirement

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of Fire Retandent AL Bubble Foam Insulation and is one of the large-scale professional investment Fire Retandent AL Bubble Foam Insulation bases in China. Annually more than 1000 containers of Fire Retandent AL Bubble Foam Insulation are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is hyperfine glass fiber cotton different from the centrifugal glass wool?

- Fine glass fiber cotton is an excellent inorganic non-metallic materials and it has a wide range of varieties. The advantages of it are good insulation, heat resistance, corrosion resistance, high mechanical strength, but the drawback is brittleness and wear resistance.It is made of glass ball or abandoned glass and goes though process of high temperature melting, drawing, winding and weaving. The diameter of the monofilaments is from several microns to twenty microns, equivalent to 1 / 20-1 / 5 of a human hair and each bundle of fiber strands is composed of hundreds or even thousands of monofilament.Glass fibers are commonly used as reinforcing materials, electrical insulating materials, insulation materials and circuit boards in the field of composite materials.Centrifugal glass wool is a silk material which is made by blowing the molten glass by centrifugal blowing processes and spraying thermoset resin. After thermal curing and deep processing, the silk material can be into products with a variety of usages.Centrifugal glass wool is a typical porous sound-absorbing material with fluffy fiber staggering inside and a lot of tiny pores existing.

- Q: The difference between glass wool of 50mm and rock wool.

- Glass wool belongs to one of the glass fiber. machine-made fiber cotton wool molten glass fibrosis cotton material belong to glass fiber. type, bulk density, low thermal conductivity, thermal insualtion, acoustic insualtion, anticorrosion, stable chemical performance. Rockwool is also called mineral wool. Use Guangde Shida rock wool and mineral raw materials to make fluffy short fine fibers. Basalt rock wool, pyroxenite, dolomite, iron ore, bauxite can be used to make matrix fiber by going through high temperature melting process and fibrosis.

- Q: Where are the differences between the glass wool board and glass wool blanket?

- Glass wool board is metal face fireproof board, mainly are rock wool and glass silk wool, which is made by using color coated steel with advanced quality as plane material, continuous fiber cotton rock wool and glass wool as core material, high-density rigid foam polyurethane as rabbet fillings, foaming and solidifying through high pressure, automatic compacting cloth cotton and composing after super-long precise double-track control molding. Performance: ⑦ has good heat-insulating property. 2, has heat insulation and fire partition performance. 3, has excellent sound insulation and sound absorption properties. Glass wool felt is coiled material to meet the needs of large-scale laying. In addition to maintaining the characteristics of heat insulation, it also has very excellent shock absorption and sound absorption characteristics, and has good absorbing effects especially for the low-frequency and various noise and vibration, which helps to reduce noise pollution and improve the working environment. This kind of material can also be arbitrarily cut according to needs in the construction, mainly used for interior architecture, damping system, vehicle, refrigeration equipment adn damping, sound absorption, noise reduction of household appliances, whose effect is very good. Glass wool felt with aluminum foil on the surface also has strong thermal radiation resistance, which is wonderful lining material for high temperature workshops, control room, inner wall of machine room, compartment and flat top.

- Q: Whether the rigid section of aluminium foil glass wool can be twined with glass fiber cloth

- This is not necessary, it depends on the place the shell is used, the best thing is to add a layer of insulation tape.

- Q: What is the construction process of external wall glass?wool?board?

- First, fix the glass wool to the wall with insulation supporting pins to prevent falling. A vapor barrier must be built on the surface of glass wool in order to prevent moisture condensation in the air within the glass wool, which may lead to the decrease of thermal insulation performance. (1) base treatment 1) the vertical control line of the entire surface must be correct, and the verticality of corners must be strictly controlled. 2) clean the floating dust, greasy dirt of release agents of concrete wall surface, masonry wall projections must be removed with a small shovel. 3) clean up the concrete blocks, slags in the joint part of shear walls, then repair again, according to the thickness of ash cake with the proportion of 1:3, and paster with cement mortar.

- Q: Whose thermal insulation performance is the best between glass wool felts and cystosepiments?

- The construction methods are different. The cystosepiments are certainly better than glass wools. But cystosepiments are rigid plates, while the glass wool felts are soft. From the thermal insulation property,

- Q: What is the price of glass wool felt ?

- Wool felt volume: 1.2 X 1 X 0.5 = 0.6 cubic meters. The price of one wool felt: 1100 * 0.6= 660 yuan. Wool felt area: ?1.2 * 1 =1.2 m2. Price of one square meter wool felt : 660 / 1.2 =550 yuan

- Q: Is centrifugal glass wool board suitable for home use?

- A large number of people think that glass wool boards are harmful and that it will cause itch when contacting with the skin. And the effect is not obvious used in the surface, so it is generally used in the wall sandwich. They are harmless for wool boards have been checked, and only those which have passed the national inspection are allowed to be sold for home use. But do not use it in the surface as it is fiber products.

- Q: Why use reflective paper for pipeline package? Such as the caliduct in home is wrapped with a layer of reflective paper outside a layer of glass wool.

- That 's not called reflective paper but aluminum foil, which is used to insulate heat. And pipes buried in the ground is also wrapped with this for heat insulation and errosion prevention.

- Q: What are the differences between rock wool and glass wool?

- Rock wool board has short silk and glass wool has long silk,

Send your message to us

Glass Wool Al+Cpe One Layer Bubble Foam for Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords