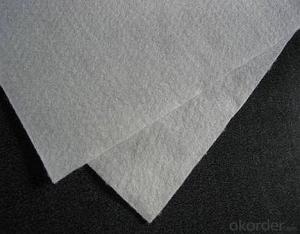

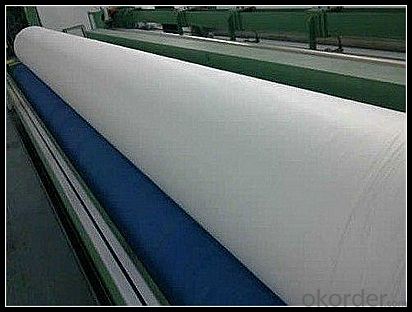

Geotextile Cloth Nz - High Stabilization and Performance Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Geotextiles

These geotextile filter fabric materials prevent the migration of fine soils to the spaces between rock particles. The migration of fine soil into your gabion structure can cause subsidence problems below or behind the gabion structure in time if not applied correctly and will stir up problems – especially in sandy soils. Clay soils do not generally require a geotextile filter fabric as they seldom leach through the basket section. We recommend using a suitable geotextile where the gabion is in contact with earth, this will limit any movement of soils through a gabion structure. In soft soil foundations especially and wherever overlaps or joins are required, we suggest a minimum overlap of 300mm(1 ft).

Benefits

High soil confinement for greater load distribution

Durable and superior damage resistant

High modulus, for immediate structural support

Unique weave optimizing both strength and filtration properties

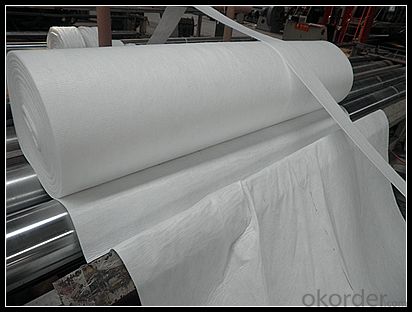

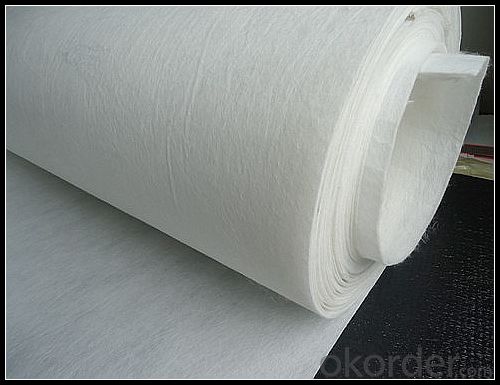

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Geotextile 300g * 600mm * 300g is how is it?

- No you say 300g * 600mm * 300g this specification of the product, according to reason should be 300g * 0.6mm * 300g product 300g * 0.6mm * 300g product is a composite geomembrane specifications, also known as two cloth a film , Composite geotextile. That is, both sides of the upper and lower sides of a layer of 300g geotextile, the middle folder 0.6mm thickness of the plastic film. Composite geomembrane is to play the role of anti-seepage, generally used for water conservancy project seepage, civil engineering seepage and so on. The geotextile is from the water, reinforcement, protection, and can not achieve the role of anti-seepage. 300g * 0.6mm * 300g composite geomembrane price is generally between 11.5-13 yuan. You can do the next reference.

- Q: What are the specifications for geotextiles used in erosion control mats?

- The specifications for geotextiles used in erosion control mats typically include properties such as high tensile strength, durability, UV resistance, and permeability to water. These geotextiles are often made from synthetic materials like polypropylene or polyester, with specific weight and thickness requirements to ensure effective erosion control. Additionally, they may need to meet certain industry standards or certifications for quality assurance.

- Q: Can geotextiles be used in stormwater detention systems?

- Yes, geotextiles can be used in stormwater detention systems. Geotextiles are commonly used in these systems to separate the soil and aggregate layers, to provide filtration and drainage, and to enhance the overall stability and performance of the system.

- Q: Seepage geotextile and impervious geomembrane

- Seepage geotextile is a short wire geotextile, the main thing is to filter water leakage. Impermeable geomembrane is used to waterproof, so the difference between the two is great.

- Q: How do geotextiles contribute to climate change adaptation?

- Geotextiles contribute to climate change adaptation by providing effective erosion control and soil stabilization measures. They help prevent soil erosion, which reduces the risk of landslides and other natural disasters caused by heavy rainfall and erosion. Geotextiles also improve water infiltration and drainage, leading to better water management in areas prone to flooding or droughts. Additionally, they promote vegetation growth, which aids in carbon sequestration and reduces greenhouse gas emissions. Overall, geotextiles play a crucial role in mitigating the impacts of climate change and enhancing the resilience of landscapes and infrastructure.

- Q: What are the types of geogrids?

- Geogrid type is a lot of it, steel-plastic geogrid / convex knot steel-plastic geogrid / overall plastic geogrid / fiberglass geogrid, etc.

- Q: What are the factors to consider when maintaining geotextiles?

- When maintaining geotextiles, there are several factors to consider. Firstly, regular inspection is crucial to identify any signs of damage or wear. It is important to promptly address any issues to prevent further deterioration. Secondly, proper cleaning techniques should be employed to remove debris, sediment, and other contaminants that may accumulate on the geotextile. This can involve gentle washing or vacuuming, depending on the specific type of geotextile and its application. Additionally, it is essential to follow manufacturer guidelines and recommendations for maintenance, as different geotextiles may have varying requirements. Lastly, monitoring the effectiveness of the geotextile over time is essential to ensure that it continues to perform its intended function. This can involve assessing its stability, porosity, and filtration capabilities, among other factors.

- Q: What are the factors to consider when designing geotextile tubes for dewatering?

- When designing geotextile tubes for dewatering, there are several factors to consider. These include the nature and composition of the sediment or sludge to be dewatered, the required dewatering rate, the size and shape of the geotextile tubes, the strength and permeability of the geotextile material, the location and environmental conditions, and the availability of equipment for filling and handling the tubes. Additionally, factors such as cost, durability, and the potential for reuse or disposal of the dewatered material should also be taken into account.

- Q: Can geotextiles be used in retaining wall drainage systems?

- Yes, geotextiles can be used in retaining wall drainage systems. Geotextiles are commonly used as a filter fabric to prevent the migration of fine particles into the drainage system, while allowing water to flow through. By placing geotextiles behind the retaining wall, they help to enhance the drainage efficiency and overall stability of the system.

- Q: How do geotextiles help in separating different soil layers?

- Geotextiles help in separating different soil layers by acting as a barrier that prevents the mixing of soils. They are placed between different soil layers to create a division, allowing each layer to maintain its unique characteristics and properties. This separation prevents soil erosion, maintains stability, and enhances the overall performance of the soil structure.

Send your message to us

Geotextile Cloth Nz - High Stabilization and Performance Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords