Geotextile of PP for Highway 150g/m2 Manufacture China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8000 cm²

- Supply Capability:

- 100000 cm²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geotextile of PP for Highway 150g/m2 Manufacture China

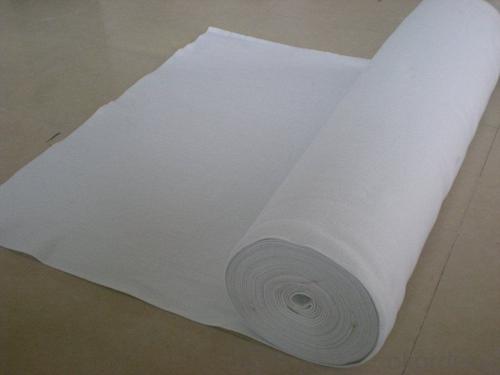

Description Geotextile of PP for Highway 150g/m2 Manufacture China

The permeable geotextile is a textile material of planar Structure used as an integral part in the placement of Gabion Baskets and mats.

It is a product made from Synthetic Fibers, non biodegradable, linked together by means of Thermal and Mechanical processes. Characterised by its structure and permeable, Great tensile strength, Tear and Chemical deterioration.

Features Geotextile of PP for Highway 150g/m2 Manufacture China

good water absorption and permeability

high tensile strength

strong anti-deformation

Good tenacity

high density

loose structure

Applications Geotextile of PP for Highway 150g/m2 Manufacture China

Highway

coastal beach for reinforcement

filtration

IMages of Geotextile of PP for Highway

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 14 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What are the considerations for geotextile installation?

- Some considerations for geotextile installation include site preparation, proper anchoring techniques, selecting the appropriate geotextile material for the specific application, ensuring proper overlap and seam strength, and proper maintenance and inspection of the installed geotextile.

- Q: In the river within the construction of flexible piping can use geotextile to do anti-floating measures

- Yes, I am specialized in producing the installation

- Q: What are the key differences between woven and nonwoven geotextiles?

- The key differences between woven and nonwoven geotextiles lie in their manufacturing processes and physical characteristics. Woven geotextiles are made by interlacing yarns or fibers together to create a stable and strong fabric. On the other hand, nonwoven geotextiles are produced by bonding or felting fibers together without any weaving process. In terms of physical characteristics, woven geotextiles generally have higher tensile strength and puncture resistance due to their interlaced structure. They also offer better filtration properties as the open spaces between the woven yarns allow for effective water flow. Nonwoven geotextiles, however, have a higher permittivity, meaning they have a greater ability to allow water to pass through. Another notable difference is their durability. Woven geotextiles tend to be more resistant to UV degradation and offer better long-term performance, making them suitable for applications that require high strength and stability over time. Nonwoven geotextiles, although less durable, are often used for short-term projects or where filtration and separation are the main requirements. Overall, the choice between woven and nonwoven geotextiles depends on the specific application and desired properties. Woven geotextiles are typically favored for their strength and longevity, while nonwoven geotextiles are preferred for their filtration capabilities and cost-effectiveness in certain applications.

- Q: How to judge the geotextile test results are reliable

- Determine whether the tensile test results of the material are reliable, depending on whether the tensile process of the material to be tested during the test has reached the state required by this detection method. As a tensile test, to test the tensile strength and elongation of the material under specified conditions. Stretching process, the material to be tested to be uniform force, the test machine fixture holding the sample to be solid, the sample does not produce slip nor be caught damage. This is the test process of the requirements of the test machine fixture and the installation of the sample requirements, only to meet this requirement and other requirements, the test results may be accurate. Geotechnical composite materials - Geosynthetics - Staple acupuncture non - woven geotextiles GB / T-1998 Geosynthetics - Filament spunbonded acupuncture non - woven geotextiles GB / T - 1998 Geosynthetics Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetic materials GB / T - 1998 Geosynthetics - Geological synthetic materials Polyvinyl chloride geomembrane GB / T-1999 Geosynthetics Plastic geogrid GB / T-1999 Geosynthetics Plastic flat wire braided geotextiles GB / T-2002 Geosynthetics Plastics 3D geogrids GB / T-2002 geosynthetics / outer composite geotextile

- Q: What are the specifications for geotextiles in retaining wall construction?

- The specifications for geotextiles in retaining wall construction typically include requirements for strength, permeability, and durability. The geotextile should have sufficient tensile strength to withstand the forces exerted by the retained soil, as well as the ability to allow water to pass through, preventing hydrostatic pressure buildup. It should also possess high puncture resistance and UV stability to ensure long-term performance in outdoor environments. Additionally, the specifications may outline requirements for the geotextile's weight, thickness, and installation methods to ensure proper functionality and compatibility with the specific retaining wall design.

- Q: Are geotextiles effective in preventing weed growth?

- Yes, geotextiles are effective in preventing weed growth. They act as a physical barrier that inhibits weed growth by blocking sunlight and preventing weed seeds from germinating. Additionally, geotextiles allow for water and air permeability, ensuring proper drainage while still suppressing weed growth.

- Q: How do geotextiles help with soil stabilization?

- Geotextiles help with soil stabilization by providing a barrier that separates the soil layers, preventing them from mixing and maintaining their structural integrity. This prevents erosion, improves drainage, and enhances the overall stability of the soil, reducing the risk of slope failure and ensuring long-term stability of the area.

- Q: Can geotextiles be used in geotechnical engineering?

- Yes, geotextiles can be used in geotechnical engineering. Geotextiles are commonly used in geotechnical engineering for applications such as soil stabilization, erosion control, filtration, drainage, and reinforcement. They provide various benefits such as improved soil strength, increased load-bearing capacity, and enhanced drainage capabilities. Geotextiles are versatile and widely employed in a range of geotechnical projects, including road construction, retaining walls, landfills, and slope stabilization.

- Q: How do geotextiles help in reinforcing soil?

- Geotextiles help in reinforcing soil by providing a stable support system. They act as a barrier, distributing loads and reducing stress on the soil. Geotextiles also improve soil drainage, prevent erosion, and promote soil stability, ultimately enhancing the overall strength and durability of the soil.

- Q: Concrete maintenance with geotextile, Tonglu how to buy

- Huazhi geotextile material manufacturers

Send your message to us

Geotextile of PP for Highway 150g/m2 Manufacture China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8000 cm²

- Supply Capability:

- 100000 cm²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords