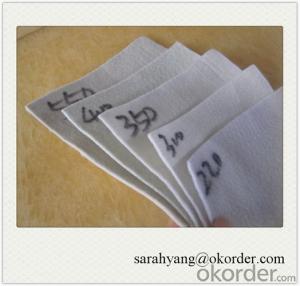

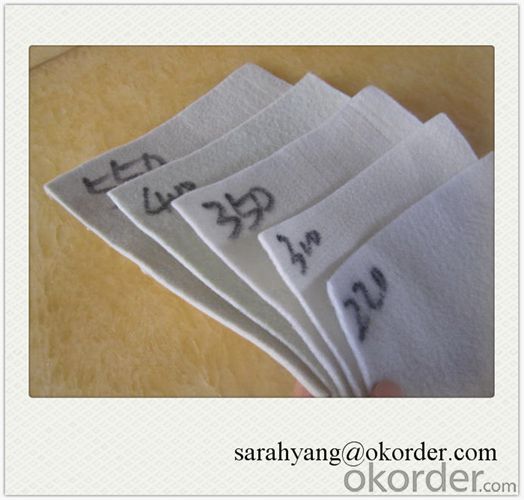

Geotextile 300g M2 Polypropylene Filter Non-Woven Geotextile for Highway, Railway, Dam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

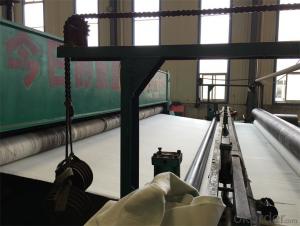

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

Use of polyester staple fiber nonwoven fabric with different physical properties (particle size, distribution, consistency and density, etc.) of the building materials (such as soil and sand, soil and concrete, etc.) in isolation. Make no loss between two or more materials, not mixed, maintains the whole structure and function of material, to reinforce structure load bearing capacity.

Filament Spunbond Nonwoven Geotextile Property:

Good creep property and hydraulics property,resistance to corrosion,

excellent anti-aging and heat-resistance quality.

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FQR

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: How do geotextiles help in stabilizing embankments?

- Geotextiles help in stabilizing embankments by providing reinforcement and erosion control. They are placed within the soil layers, acting as a barrier to prevent soil movement and promote stability. The geotextiles increase the shear strength of the soil, reducing the risk of slope failure. Additionally, they allow for water drainage while preventing the loss of fine particles, therefore minimizing erosion and maintaining the integrity of the embankment.

- Q: Geotextile price specific how to develop?

- Each type of product in the market before the sale, the pricing will take into account all aspects of the factors, very strict and careful investigation, geotextile is also true. The first is the product quality is the second product specifications and standards to Hongxiang new material short wire geotextile, for example, sub-weight (80-1500g / ㎡), the quality standard is a requirement, divided into non-standard, by White A, Sinochem, ordinary GB, Paul GB, Dahua GB and so on. Ton price is generally between 4900-7500 yuan / ton, but the weight <200g, an increase of 100 yuan / ton; weight> 800g, an increase of 500 yuan / ton. 187 & lt; 6600 & lt; 5604

- Q: Are geotextiles commonly used in landfills for leachate collection?

- Yes, geotextiles are commonly used in landfills for leachate collection. They play a crucial role in containing and filtering leachate, preventing its migration into surrounding soil and water bodies. Geotextiles provide a permeable barrier that allows leachate to drain while retaining solid waste, ensuring effective management of landfill leachate.

- Q: Are geotextiles poisonous?

- Geotextile is not toxic, the production of geotextile raw materials are polyester (PET) or polypropylene (PP). Polyester and polypropylene have become daily necessities. Many of the mineral water bottles are also produced by PET and PP raw materials.

- Q: How are geotextiles manufactured?

- Geotextiles are typically manufactured using a process called needle punching. This involves mechanically interlocking synthetic fibers together to create a strong and durable fabric. The fibers are first carded, meaning they are aligned and separated, before being fed through a machine that punches them with barbed needles. These barbs entangle and interlock the fibers, creating a stable fabric structure. Further processes such as heat setting, calendaring, and coating may be applied to enhance the geotextile's properties, such as increasing its resistance to UV degradation or improving its filtration capabilities.

- Q: Geotextile detection frequency

- GB / T-2009 / ISO9862: 2005 does not specify the frequency, but according to the general provisions of the construction material is required to declare the material inspection, the specific number of consultation with the testing agency, the general geotextile detection: thickness (sample length 1m, (Sample length 1m, the number of samples 10 10 × 10), tensile properties (wide stretch, trapezoidal tear (sample length 2m, the number of samples vertical and horizontal to the five blocks ))

- Q: How are geotextiles tested for durability?

- Geotextiles are tested for durability through various methods, including exposure to environmental factors such as sunlight, moisture, and temperature changes. Additionally, they undergo mechanical tests like puncture resistance, tear strength, and tensile strength evaluations. These tests help determine the geotextile's ability to withstand long-term use and maintain its structural integrity in different applications.

- Q: What are the factors to consider when selecting geotextiles for coastal protection projects?

- When selecting geotextiles for coastal protection projects, there are several factors to consider. Firstly, the type and quality of the geotextile material is crucial. It should be durable, resistant to UV radiation, and capable of withstanding the harsh coastal environment, including exposure to saltwater and strong waves. Secondly, the intended function of the geotextile should be taken into account. Different geotextiles offer varying levels of erosion control, filtration, and stabilization. Therefore, the specific needs of the coastal protection project, such as preventing beach erosion or stabilizing coastal structures, should be considered. Thirdly, the site conditions and project requirements play a significant role. Factors like wave energy, sediment characteristics, and slope stability need to be assessed to determine the appropriate geotextile specifications. Furthermore, the installation and maintenance requirements should be evaluated. Geotextiles that are easy to install and require minimal maintenance are often preferred, as they can save time and costs during the project's lifespan. Lastly, the cost-effectiveness and longevity of the geotextile should be taken into consideration. It is essential to balance the initial cost of the geotextile with its expected lifespan and performance to ensure a sustainable and economical solution for coastal protection.

- Q: In the laying of composite geotextile water layer, what is wf115-0.2mm type

- Supply of composite geotextile, geomembrane.

- Q: How do geotextiles help in stabilizing slopes?

- Geotextiles help in stabilizing slopes by providing reinforcement and erosion control. They are placed between soil layers to enhance their strength and prevent soil movement. Geotextiles act as a barrier, distributing the load over a wider area and reducing the risk of slope failure. Additionally, they promote drainage and filtration, preventing the accumulation of water that can weaken the soil and lead to erosion.

Send your message to us

Geotextile 300g M2 Polypropylene Filter Non-Woven Geotextile for Highway, Railway, Dam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords