Geotextil Negro Filament Geotextile, Non Woven Spunbond Needle Punch Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

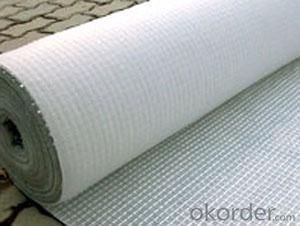

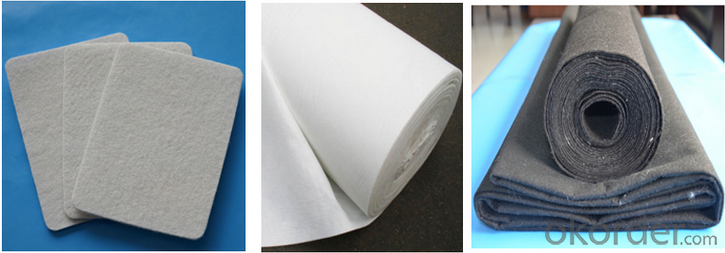

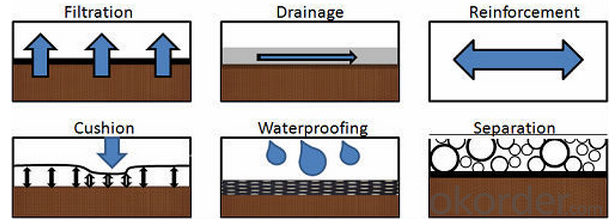

Filament Geotextiles are permeable nonwoven fabrics used to separate,filter,reinforce, protect or drainage.Geotextiles allow filtration or separation of granular layers in roads and rail applications,used to protect membranes in landfill applications,used in coastal defence applications and used in landscaping to protect surfaces and structures from weeds and root growth.

Filament Geotextiles are available as woven and non-woven .As liner protection, against physical damage, the non wovens are normally the answer.They are made up of fibers of polyester or polypropylene in random directions and punched together by needles during the manufacturing process.Geotextiles are commonly used to separate layers like clay and drainage and to protect liner from damage.

Product Details

Features:

Engineered to provide high strength and high elongation at break to ensure excellent resistance to damage during construction

Manufactured from high tenacity UV stabilised virgin polypropylene or polyester fibers which have been heavily drawn to ensure excellent long term durability in all soil types.

Manufactured using a randomly orientated web to provide completely isotropic properties,ensuring that high strength is not limited to a single direction.

Excellent uniformity with high permeability and low pore size for soil filtration.

Supplied to a maximum width of 8.0 meters,ensuring minimum waste over large construction areas.

100% polypropylene or polyester staple fibers ,needle punched and random network formation.

UV and rot resistant and biological degradation resistant.

Majority Process:

Specific Data:

cItem | Area weight | Tensile Strength | Elongation | shrinkage | Roll Size | ||

MD | CMD | MD | CMD | ||||

Unit | G/M2 | N/125px | % | % | m x m | ||

Specification | 120 | ≥350 | ≥260 | 23 | 28 | <2.0< span=""> | 1.02x1700 |

140 | ≥380 | ≥300 | 25 | 30 | <1.0< span=""> | 1.01x1500 | |

150 | ≥500 | ≥330 | 28 | 35 | <1.0< span=""> | 1.01x1500 | |

160 | ≥550 | ≥350 | 30 | 35 | <1.0< span=""> | 1.01x1400 | |

180 | ≥600 | ≥450 | 30 | 35 | <1.0< span=""> | 1.01x1200 | |

200 | ≥750 | ≥450 | 30 | 35 | <1.0< span=""> | 1.01x1100 | |

220 | ≥800 | ≥500 | 30 | 35 | <1.0< span=""> | 1.01x1000 | |

250 | ≥950 | ≥600 | 35 | 40 | <1.0< span=""> | 1.01x800 | |

FAQ:

1. How to order your geotextile?

a). Tensile strength in warp & weft direction

b). gram per meter

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

3. Delivery time

a) 19-25 days after received your deposit .

4. What is MOQ ?

a) 2000 m2 as MOQ , we can also produce sample for you .

- Q: What is geotextile cloth?

- Geogrid, geotextile, geomembrane manufacturers, specializing in the production

- Q: Geotextile Commission test how many square meters

- Geotextile performance testing generally need 1-2 square meters is enough. My company specializing in the production of geotextiles, often come to take samples to detect, are generally 1-2 square meters

- Q: Geotextile seam construction how to do

- Sewing of geotextiles All sutures must be carried out continuously (for example, spotting is not allowed). Before the overlap, the geotextile must overlap at least 150mm. The minimum stitch is at least 25 mm from the weaving edge (the edge of the material exposed). The seam of the geotextile seam is covered by a single line of thread lock. The line used for suturing should be a resin material with a minimum tension of more than 60N and is resistant to chemical corrosion and UV resistance comparable to or beyond the geotextile. Any "missing needle" on the sewn geotextile must be re-sewn in the affected area. It is necessary to take appropriate measures to prevent the soil, particulate matter or foreign matter from entering the geotextile after installation. Cloth lap according to the terrain and the use of functions can be divided into natural lap, seam or welding. Geotextile manufacturers, for your answer

- Q: Can geotextiles be used in railway construction?

- Yes, geotextiles can be used in railway construction. Geotextiles are often utilized in railway projects for various purposes such as soil stabilization, erosion control, filtration, drainage, and separation. They help improve the durability and performance of railway infrastructure by providing reinforcement, preventing soil movement, and enhancing drainage systems.

- Q: What is the difference in role of earth anchors and geotextiles in the construction of retaining wall?

- Geotextiles prevent the infiltration of the natural, insitu soil into sand or structural gravel that you may place as a foundation to the retaining wall. You can think of it as a membrane that keeps the two types of material of different densities, from gradually mixing together. A free standing retaining wall will likely not be successful as the pressure of the retained soil behind the wall will build up due to settlement, and eventually cause the wall to topple. Earth anchors that tie into the wall and extend into the backfill material (retained earth) serves to support the wall and keep it from failing.

- Q: How are geotextiles affected by UV exposure?

- Geotextiles are affected by UV exposure due to the degradation of their fibers by sunlight. This exposure can weaken the material, reducing its overall strength and durability over time. To mitigate this, geotextiles are often treated with UV stabilizers or are installed in a manner that minimizes direct exposure to sunlight.

- Q: What are the specifications for geotextiles in gas venting projects?

- The specifications for geotextiles in gas venting projects typically include factors such as the material's permeability, strength, and durability. The geotextile should have a high permeability to allow gas to pass through while preventing the migration of fine particles. It should also possess adequate strength to withstand the gas pressure and potential stresses. Additionally, the geotextile should exhibit durability to withstand environmental conditions and maintain its functionality over time.

- Q: Planting roofing geotextile lap way

- Lap 10 cm, sewing with sewing machine, I specializing in the production of roofing with geotextile, drainage board and other products, wish smooth

- Q: Concrete pavement or geotextile

- Do not add, with the asphalt Ma plug Seal if you have to choose the best choice for geotextile waterproof the best

- Q: Where to find the right geotextile

- Geotextile types are many, according to the manufacturing process of spinning, woven, woven, according to the material is divided into filaments, short wire and so on, if the most suitable geotextile should be the project requirements are not very strict , Generally like building coverage, road maintenance, etc., like this price is generally around 0.5 angle

Send your message to us

Geotextil Negro Filament Geotextile, Non Woven Spunbond Needle Punch Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords