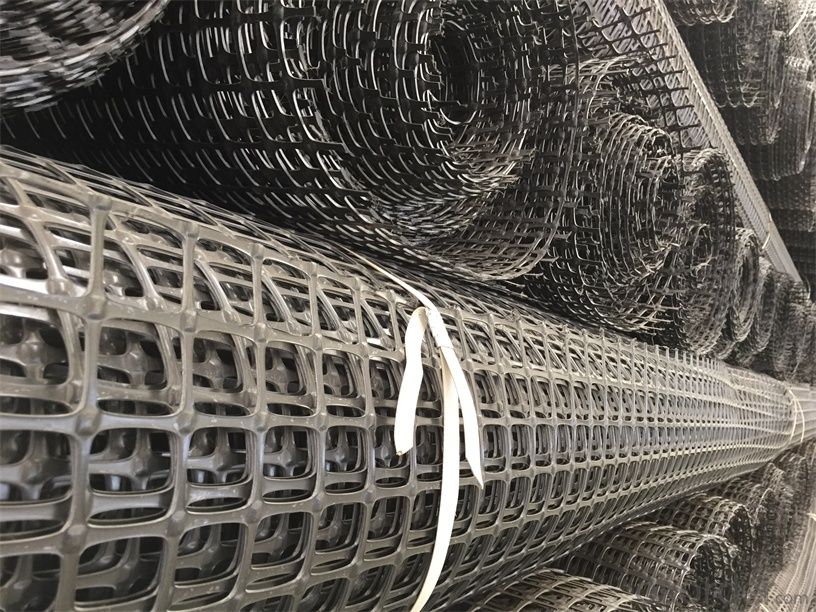

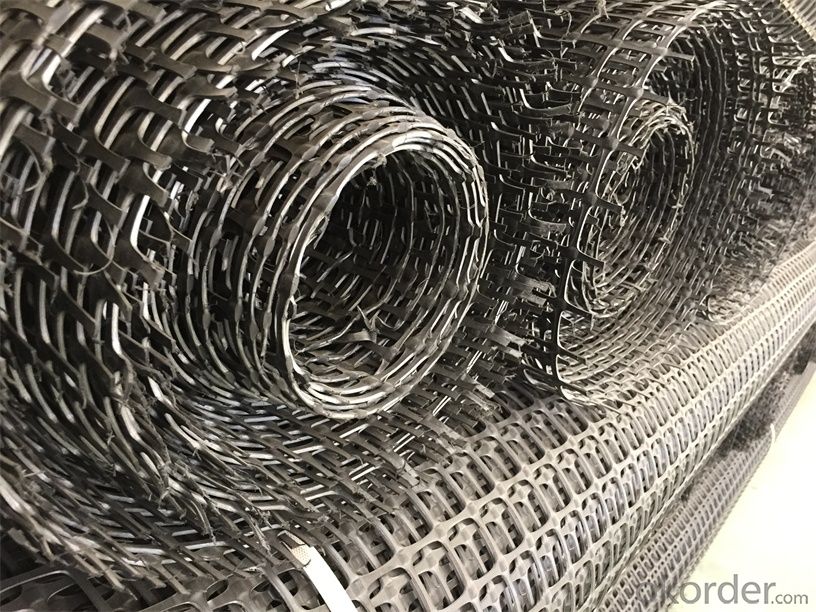

Geogrid Stragrip Sg-150 - Polyester Biaxial Plastic Geogrid with High Tensile Strength Warp Knitted Cmax

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q: Are geogrids environmentally friendly?

- Geogrids can be considered environmentally friendly as they are typically made from recycled materials and can be reused or recycled after their lifespan. Additionally, geogrids help stabilize soil, reduce erosion, and enhance drainage, leading to improved environmental conditions.

- Q: What is the difference between bidirectional geogrid and unidirectional high strength geogrid

- The uniaxial geogrid is uniform holes in the polymer extrusion molding, and then heated and shaped mesh material, according to the different raw materials can be divided into one-way one-way polyethylene polypropylene geogrid, geogrid

- Q: What are the factors that affect the design and selection of geogrids for geosynthetic reinforcement of slopes?

- There are several factors that affect the design and selection of geogrids for geosynthetic reinforcement of slopes. These factors include the slope angle, soil type and properties, anticipated loads and stresses, construction constraints, and environmental conditions. The slope angle determines the required strength and stiffness of the geogrid to resist gravitational forces and prevent slope failure. The soil type and properties, such as cohesion and internal friction angle, influence the interaction between the geogrid and the soil, affecting the required geogrid aperture size and tensile strength. The anticipated loads and stresses, such as traffic loads or groundwater pressures, determine the design strength and durability requirements of the geogrid. Construction constraints, such as access limitations or equipment availability, may influence the selection of geogrid installation methods. Lastly, environmental conditions, such as temperature variations or chemical exposure, affect the long-term performance and durability of the geogrid, influencing the choice of materials and protective measures. Overall, a thorough understanding of these factors is essential for the effective design and selection of geogrids for geosynthetic reinforcement of slopes.

- Q: How do geogrids improve the performance of geotextile sediment retention systems?

- Geogrids improve the performance of geotextile sediment retention systems by providing additional reinforcement and stability. They enhance the tensile strength of the geotextile, preventing it from stretching or tearing under the weight of sediment and water pressure. This increased strength allows the geotextile to effectively retain sediment and prevent its migration, ensuring the system's long-term performance and functionality.

- Q: What are the factors that affect the creep behavior of geogrids?

- There are several factors that can affect the creep behavior of geogrids, including the type and quality of the geogrid material, the magnitude and duration of applied load, environmental conditions such as temperature and moisture, and the installation and confinement methods used. These factors can influence the long-term deformation and performance of geogrids, making it crucial to consider them in design and engineering applications.

- Q: Why steel plastic geogrid in the test, will choose to peel out a single wire test? What are the causes and sources of this method?

- Peel out because of the more intuitive understanding of the strength of the tensile strength and extension of the length of the wire wrapped in order to protect the steel wire does not rust.

- Q: How much is the steel plastic geogrid?

- Steel plastic geogrid 70KN, 5.5 yuan per squareSteel plastic geogrid 80KN, 6.5 yuan per squareSteel plastic geogrid 100KN, 8 yuan per square

- Q: How do geogrids enhance the stability of steep railway cuttings?

- Geogrids enhance the stability of steep railway cuttings by providing reinforcement and preventing soil erosion. They are installed within the soil or rock layers to distribute the tensile forces and improve the overall strength of the cutting. This helps to reduce the risk of slope failure and maintain the stability of the railway embankment, ensuring safe and efficient train operations.

- Q: What are the long-term durability characteristics of geogrids?

- Geogrids have excellent long-term durability characteristics. They are designed to withstand harsh environmental conditions, including high temperatures, moisture, and chemical exposure. Geogrids are made from high-strength materials, such as polyester or polypropylene, which provide resistance against degradation and maintain their structural integrity over time. They have a long service life and can effectively retain soil, stabilize slopes, and reinforce paved surfaces for many years without significant deterioration.

- Q: How to do this in the geogrid in the retaining wall? Is there any remedy?

- Thermal stability - the melting temperature of the glass fiber is above 1000 DEG C, which ensures the stability of the fiberglass geogrid in the paving operation.

Send your message to us

Geogrid Stragrip Sg-150 - Polyester Biaxial Plastic Geogrid with High Tensile Strength Warp Knitted Cmax

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords