Geocells for Driveways - Polyester Geogrid with PVC Coating (Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyester Geogrid with PVC Coating(Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

1. Introduction of Polyester Geogrid with PVC Coating(Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

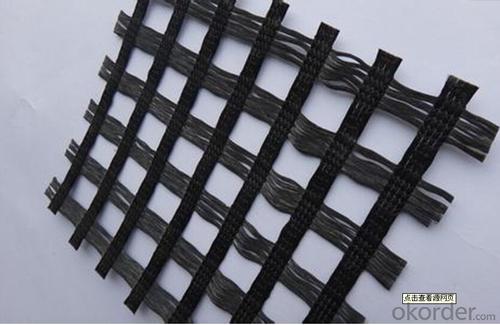

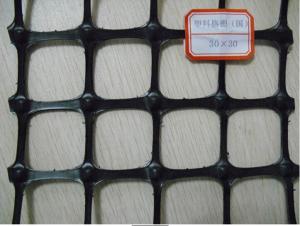

High strength polyester warpknitting geogrid adopts high strength, high modulus, and low shrinkage twisting industrial polyester fiber as raw material. It is warp knitted with oriented structure and in the condition of no bending among warp and weft direction.

Its crossing points are bundled and bended together by high strength long polyester fiber forming tough conjunction. Then it forms into mesh size product after coated with high quality watersoluble PVC which improves its strength, various technical standards and gives full play of its mechanical property.

2. Performance of Polyester Geogrid with PVC Coating(Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

High tensile strength

Low elongation

Excellent temperature resistant

Good anti-aging

Good alkali-resistance

3. Application of Polyester Geogrid with PVC Coating(Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

Strengthening soft roadbed of high-class roads and high speed railways, separating different subgrade soil material.

Using in reclamation engineering, dam, landslides and retaining wall.

Enhancing various roadbeds.

Strengthening soft roadbed of airport.

4. Packing and Delivery of Polyester Geogrid with PVC Coating(Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

- Q: Glass fiber grille is not geogrid

- Yes, one of the three categories of geogrid. Fiberglass grille is another kind of glass fiber geogrid.

- Q: What is the difference between woven and non-woven geogrids?

- Woven geogrids are made by weaving polyester or polypropylene yarns together, resulting in a strong and flexible grid structure. On the other hand, non-woven geogrids are manufactured by bonding or needle-punching synthetic fibers, creating a random network of fibers. The main difference lies in their structure and manufacturing process, which influences their mechanical properties and application. Woven geogrids tend to have higher tensile strength and are suitable for stabilizing soil in applications such as road construction, while non-woven geogrids are more commonly used for erosion control and filtration purposes.

- Q: Are geogrids suitable for use in seismic zones?

- Yes, geogrids are suitable for use in seismic zones. Geogrids are engineered materials that provide reinforcement and stability to soil. They are designed to improve the performance of soil structures in various conditions, including seismic events. Geogrids can help increase the tensile strength and stability of soils, reducing the risk of soil liquefaction and enhancing the overall resilience of structures in seismic zones.

- Q: Can geogrids be used in reinforcement of soil-lime mixtures?

- Yes, geogrids can be used in the reinforcement of soil-lime mixtures. Geogrids are commonly used in civil engineering and construction projects to improve the stability and strength of soil-lime mixtures. They provide additional tensile strength, prevent soil erosion, and enhance the load-bearing capacity of the mixture. By adding geogrids, the performance and durability of soil-lime mixtures can be significantly improved.

- Q: What is the single geogrid 60kN/m

- Should be a one-way geogrid, 60kN/m grid strength

- Q: Geogrid is mainly used for what?

- Application of unidirectional geogrid:Unidirectional geogrid is a kind of high strength structural material, which is suitable for highway, municipal road, railway, runway and so on. 1, strengthen the embankment, can effectively improve the load distribution, and the bearing capacity and service life of the subgrade stability; 2, preventing the material loss caused by the deformation of subgrade, and even rupture; 3, can withstand greater load; 4, applicable to all kinds of soil, no place to be drawn, saves time and labor; and the use of construction simple biaxial geogrid:

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth walls for bridge abutments?

- Yes, geogrids can indeed be used for reinforcement of mechanically stabilized earth walls for bridge abutments. Geogrids are commonly used in such applications as they provide additional tensile strength to the soil, improving its overall stability and preventing potential failure. By distributing and transferring loads, geogrids help increase the load-bearing capacity of the soil, making them an ideal choice for reinforcing mechanically stabilized earth walls used in bridge abutments.

- Q: In the middle of geogrid foundation treatment process is belongs to the concealed work it

- After the completion of the project is not visible to the process or project site, are known as the hidden works, so the geogrid must belong to the hidden works

- Q: Can geogrids be used in ground stabilization for water treatment plants?

- Yes, geogrids can be used effectively in ground stabilization for water treatment plants. Geogrids are a type of geosynthetic material that provide reinforcement and stability to soils, making them ideal for preventing soil erosion and improving the load-bearing capacity of the ground. By using geogrids, water treatment plants can ensure the stability and longevity of their infrastructure, preventing soil settlement and potential damage caused by heavy equipment and machinery. Additionally, geogrids can help control soil erosion and maintain the integrity of slopes or embankments surrounding the water treatment plant, further enhancing its overall stability.

- Q: Can geogrids be used in bridge abutments and approach embankments?

- Yes, geogrids can be used in bridge abutments and approach embankments. Geogrids are commonly used in these applications to provide soil reinforcement and stability, preventing soil erosion and enhancing load-bearing capacities. They help distribute loads more evenly, reduce settlement, and increase the overall strength of the structure. Additionally, geogrids are cost-effective and easy to install, making them a popular choice for bridge construction projects.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Geocells for Driveways - Polyester Geogrid with PVC Coating (Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords