GB 45#/SAE 1045 Steel Round Bar 16mm-18mm

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GB 45#/SAE 1045 Steel Round Bar 16mm-18mm

Description:

-Specification: 16mm-18mm

-Length: 6m、12m

-Standard: GB/SAE/Japanese Standard

-Material: GB 45#/SAE1045/S45C

Chemical Composition of GB 45#/SAE 1045 Steel Round Bar 16mm-18mm:

| C | Si | Mn | P | S | Ni | Cr | Cu |

| 0.42-0.50 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | ≤0.30 | ≤0.25 | ≤0.25 |

Packaging & Delivery of GB 45#/SAE 1045 Steel Round Bar 16mm-18mm:

Packaging Detail: All goods are packed in bundle with steel strips and shipped by break bulk vessel or container (depend on target market and different ports)

Delivery Detail: 45 days

MOQ: 50 tons per specification; we can negotiate the quantity if the specification is normal or we have stock of one specification.

Weight: The price invoicing on theoretical weight basis or actual weight basis depends on customer’s request.

Shipment: The shipment of bulk break or container is depends on customer’s request and the situation of the port of destination.

Documents given: Full set of original clean on board bill of lading; Original signed commercial invoice; Original packing list; Policy of insurance; Certificate of origin and what the target market needs.

Payment:

-Invoicing on theoretical weight or actual weight a s customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

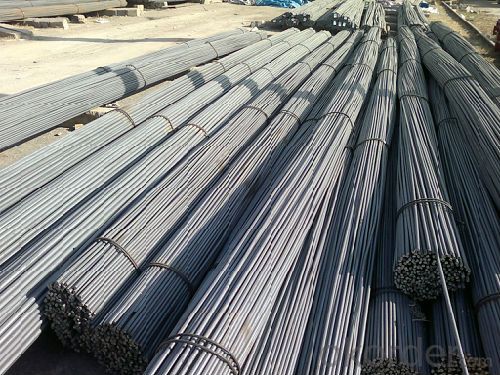

Images of GB 45#/SAE 1045 Steel Round Bar 16mm-18mm:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: What is the fatigue strength of a steel round bar?

- The fatigue strength of a steel round bar refers to its ability to withstand repeated or cyclic loading without failure. It is a measure of the bar's resistance to fatigue or fatigue-induced failure. The fatigue strength of a steel round bar depends on various factors such as the material composition, manufacturing process, surface finish, and geometry of the bar. To determine the fatigue strength of a steel round bar, fatigue tests are typically conducted using standardized procedures. These tests involve subjecting the bar to repeated loading cycles that simulate real-world conditions. The bar is subjected to a specific stress amplitude or stress range, and the number of cycles required to cause failure is recorded. The fatigue strength of a steel round bar is usually expressed as the stress level or stress range at which failure occurs after a certain number of cycles, such as 10^6 cycles or 10^7 cycles. This value is commonly referred to as the fatigue limit or endurance limit. For steel round bars, the fatigue strength is generally high compared to other materials, and it is usually expressed in terms of stress in megapascals (MPa) or pounds per square inch (psi). It is important to note that the fatigue strength of a steel round bar can vary depending on factors such as the presence of surface defects, residual stresses, temperature, and environmental conditions. Therefore, it is crucial to consider these variables when determining the fatigue strength of a specific steel round bar for a given application.

- Q: What are the advantages of using chromium-vanadium alloy steel round bars?

- Some advantages of using chromium-vanadium alloy steel round bars include: 1. High strength and toughness: Chromium-vanadium alloy steel has excellent strength and toughness properties, making it suitable for applications requiring durability and resistance to wear and tear. 2. Improved corrosion resistance: The addition of chromium enhances the alloy's corrosion resistance, making it resistant to rust and other forms of corrosion, even in harsh environments. 3. Enhanced hardenability: Chromium-vanadium alloy steel can be easily heat-treated to achieve high hardness levels, allowing for increased wear resistance and improved overall performance. 4. Good machinability: The alloy steel round bars can be easily machined and fabricated, making them convenient to work with in various manufacturing processes. 5. Cost-effective: Chromium-vanadium alloy steel offers a good balance between performance and cost, making it a cost-effective choice for many applications compared to other high-performance alloys.

- Q: Can steel round bars be used in the medical industry?

- Yes, steel round bars can be used in the medical industry. Stainless steel round bars, in particular, are commonly used in medical applications due to their corrosion resistance, strength, and durability. These bars can be used in the production of various medical devices and equipment, including surgical instruments, orthopedic implants, dental tools, and prosthetics. The high-quality stainless steel ensures that these products can withstand the demanding conditions of medical environments and provide optimal performance and safety to patients. Additionally, stainless steel round bars can be easily sterilized, making them suitable for use in sterile medical settings.

- Q: What are the tolerance standards for steel round bars?

- The tolerance standards for steel round bars vary depending on the specific requirements and industry standards. Generally, tolerance standards for steel round bars are specified in terms of diameter, straightness, length, and surface finish. These tolerances ensure that the bars meet the desired dimensions and quality standards, allowing for proper fit and function in various applications.

- Q: Are steel round bars suitable for the production of springs?

- Yes, steel round bars are suitable for the production of springs. Steel round bars are commonly used in the manufacturing of springs due to their high strength, durability, and ability to withstand heavy loads and repeated stress. They provide the necessary rigidity and flexibility required for effective spring functioning. Additionally, steel round bars can be easily shaped and manipulated into various spring designs, making them a preferred choice in the production of springs.

- Q: Can steel round bars be used in the production of musical instruments?

- Certainly! Musical instruments can indeed be produced using steel round bars. Steel, being a versatile material, possesses a wide array of desirable attributes including strength, durability, and resonance. Although wood is typically the go-to material for crafting musical instruments, steel can be utilized in specific instances to augment the instrument's sound and performance. For instance, steel round bars can be implemented in the fabrication of various components such as keys or valves for wind instruments like saxophones or trumpets. Moreover, these bars can be employed to construct the internal support systems in instruments like guitars or cellos, thereby providing stability and enriching tonal qualities. Furthermore, steel round bars can be employed in the construction of percussion instruments such as steel drums or xylophones, where their robust and resonant attributes are highly sought after. On the whole, although wood remains the more prevalent choice in the realm of musical instrument production, steel can certainly be employed in specific scenarios to attain desired sound characteristics and structural integrity.

- Q: How are steel round bars classified based on their shape?

- Steel round bars can be categorized into two main groups, namely hot-rolled round bars and cold-drawn round bars, depending on their shape. Hot-rolled round bars are produced by heating a steel billet until it becomes malleable and then passing it through a series of rollers to achieve the desired shape. This manufacturing process results in a rougher surface texture and a slightly larger diameter when compared to cold-drawn round bars. Hot-rolled round bars find common usage in construction, engineering, and manufacturing applications where strength and durability play a crucial role. On the other hand, cold-drawn round bars are manufactured by pulling a hot-rolled round bar through a series of dies at room temperature. This process enhances the dimensional accuracy, surface finish, and mechanical properties of the steel. Cold-drawn round bars possess a smoother surface texture and a more precise diameter, making them suitable for applications that demand tight tolerances, such as precision machining, automotive components, and machinery shafts. In conclusion, the classification of steel round bars, based on their shape, is determined by the specific manufacturing process employed. Hot-rolled round bars exhibit rougher surfaces and slightly larger diameters, while cold-drawn round bars boast smoother surfaces and more precise dimensions. The choice between these two categories depends on the specific requirements of the given application.

- Q: Can steel round bars be used for making electrical components?

- Whether steel round bars can be used for making certain electrical components depends on the specific requirements and applications. Steel is a versatile material that possesses good electrical conductivity and high durability, making it well-suited for a variety of electrical applications. However, when it comes to components that necessitate specific electrical properties or insulation, copper or aluminum may be more commonly utilized. Furthermore, in order to prevent corrosion or enhance electrical conductivity, it may be necessary to subject steel round bars to surface treatments or coatings. Ultimately, the appropriateness of utilizing steel round bars for manufacturing electrical components should be evaluated in accordance with the specific requirements and regulations of the intended application.

- Q: Can steel round bars be used for making automotive chassis?

- Certainly, automotive chassis can be constructed using steel round bars. Due to its impressive strength and durability, steel is a prevalent material in the production of automotive chassis. The utilization of round bars made from steel ensures outstanding structural integrity, allowing them to endure the immense loads and forces that a vehicle's chassis encounters. Moreover, incorporating steel round bars in automotive chassis contributes to enhancing the overall safety of the vehicle by providing a robust and inflexible frame. Furthermore, steel is reasonably affordable and easily accessible, rendering it a favored selection for automotive manufacturers.

- Q: What is the weight of a steel round bar?

- The weight of a steel round bar is determined by its dimensions, specifically its diameter and length. You can determine the weight using the formula: weight = volume × density. To determine the volume of the steel round bar, you can use the formula for the volume of a cylinder: volume = π × (diameter/2)^2 × length. Here, π represents a mathematical constant approximately equal to 3.14159. The density of steel varies depending on the type and grade, but it typically falls around 7.85 grams per cubic centimeter (g/cm³) or 7850 kilograms per cubic meter (kg/m³). By substituting the appropriate values into the formula, you can calculate the weight of the steel round bar in the desired unit, such as grams, kilograms, pounds, and so on.

Send your message to us

GB 45#/SAE 1045 Steel Round Bar 16mm-18mm

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords