Thickness: 0.15 - 2.0 mm

Technique: Hot Rolled

Application: Container Plate

Surface Treatment: Galvanized

Secondary Or Not: Non-secondary

Certification: CE

Special Pipe: Thick Wall Pipe

Alloy Or Not: Non-alloy

Section Shape: Other

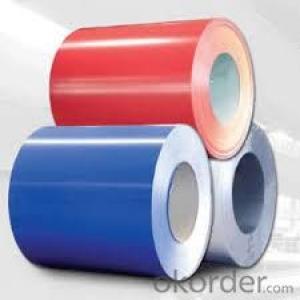

Galvanized Steel Coil Dx51d+z CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Quick Details:

2.Packaging & Delivery

| Packaging Details: | standard package |

|---|---|

| Delivery Detail: | 1-4 week |

cold rolled galvanizing steel coil

galvanized iron steel coil

Thickness | 0.15mm--2.0mm |

Width | 50--1250mm |

Zinc Coating | 40gsm—275gsm |

Spangle | Big, small regular spangle and zero spangle |

Surface Treatment | Chromate, Galvanized, Skin Pass, Passivity and Oiled(un-oiled) |

ID | 508mm or 610mm |

Coil Weight | 3--7 Metric Tons and as requirements |

Production | 12,000 metric tons per month |

More information of Galvanized Steel Coils/GI/PPGI/HDG | |

Payment Term | T/T or L/C (We usually charge 30% of the deposit first.) |

Delivery Port | Qingdao Port or Tianjin Port |

Delivery Time | Within 20 days after receipt of T/T or L/C |

MOQ | 25 metric tons or one 20 feet container |

Application | General use, Color coating, Corrugated Roofing making, Outside of the buildings Structure, Deep Drawing and etc. |

Ambition | Reliable product, Competitive price, On-time delivery and High standard service. |

5.What is the application of Steel Coil?

There are two sides,one is out side: Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth;the other is inside: Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter.

- Q: How are steel coils used in the production of agricultural systems?

- Steel coils are often used in the production of agricultural systems due to their durability and strength. These coils are typically used in the construction of machinery and equipment that are essential in agricultural operations. One common application of steel coils is in the manufacturing of farming machinery such as tractors, plows, and cultivators. These machines require sturdy components to withstand the demanding conditions of the agricultural environment. Steel coils are used to fabricate the frames, chassis, and other structural parts of these machines, providing the necessary strength and support. Steel coils are also used in the production of irrigation systems, which are crucial for efficient water management in agriculture. These coils are utilized in the construction of pipes, valves, and fittings, ensuring the durability and longevity of the irrigation system. Additionally, steel coils are used to manufacture storage tanks and silos, which are essential for storing and preserving agricultural products such as grains, seeds, and fertilizers. Furthermore, steel coils find application in the construction of greenhouses and agricultural buildings. The coils are used to fabricate the structural framework, providing stability and resistance against environmental factors. Steel coils are also used in the production of fencing and enclosures to protect crops and livestock from external threats. In summary, steel coils play a vital role in the production of agricultural systems by providing the necessary strength, durability, and stability required for farming machinery, irrigation systems, storage facilities, and agricultural structures. Their usage ensures that these systems can withstand the demanding conditions of the agricultural industry and contribute to efficient and sustainable farming practices.

- Q: Help me compare the speed of sound in air, water, and steel please?Thanks.

- Speed Of Sound In Steel

- Q: What are the main factors that affect the flatness of steel coils?

- The main factors that affect the flatness of steel coils include the quality of the raw material used, the thickness and width of the coil, the temperature and humidity during the manufacturing process, the tension applied during coiling, and the cooling and leveling processes employed.

- Q: How are steel coils processed and shaped into various products?

- Steel coils are processed and shaped into various products through a series of manufacturing processes. First, the steel coil is uncoiled and cleaned to remove any impurities. Then, it goes through a process called leveling, where the coil is flattened and straightened. Next, the steel is cut into the desired length or shape, using techniques like shearing or slitting. After that, it may undergo additional processes such as forming, bending, or rolling to give it the desired shape. Finally, the steel is often treated with coatings or finishes to enhance its durability and appearance.

- Q: i would like to make a dmascus steel knife, i have the cable but im not sure if its damascus steel or not, how do i tell? and if it isnt damascus steel how do i make a bar of it?

- Here's what you need, the cable should be a minimum of 9/16 with large wires. You need some borax (20 mule team from the store). A good hot coal, coke, or gas forge. If the cable has fiber rope in the center it will need to be removed. Fuse the ends of the cable to keep them from coming apart. I use my welder and while I'm at it I weld a handle to make it easier. Heat it in the forge when the forge is properly heated, rotate it. Some people will burn the oil out, but I've found that the forge does that just fine. Rotate the cable while it's heating. When it begins the turn red pull it out and sprinkle the borax over it, don't hold back use a lot. It will begin to melt and bubble into the steel. Put the cable back in the forge, rotate and watch. This is the critical part. When the steel starts to turn from orange/yellow to almost yellow/white take it out and lightly (I use a 2lb hammer) begin hammering the cable into a square or rectangle. If you do it right you'll notice that it will begin to fight the hammer, that's when you know the weld it taking place. You'll have to repeat the process down the length of the cable. Once you have the billet made you can begin the process of shaping the edge and tang. Once you have it shaped, follow proper forge procedure then grind all the yuck off and finish shaping. Then harden and temper and finish it out. Good luck. I almost forgot a very important part. Befor you start hammering put the cable in a vice while at welding temp (if you are strong you can use a couple of plyers) and twist it tight. On the next heat hold the cable in your left and and lay it on the anvil. Concentrate on your light hammer blows being on your side of the cable. This forces the cable strands together. If you are using smaller cable like 9/16 you can double the cable up and weld two peices together, it is easier and makes for a prettier blade. Doing this you don't have to worry about twisting the cable and you can hit it much harder to start with.

- Q: What is the process for uncoiling and recoiling steel coils?

- The process for uncoiling and recoiling steel coils involves various steps. Firstly, the steel coil is securely placed on a mandrel or a coil car. Next, the coil is unfastened or cut to release the bands holding it together. Then, a suitable uncoiling machine is used to gradually unwind the coil, ensuring it is done in a controlled manner to prevent damage or accidents. Once the desired length of steel is unwound, it can be cut or sheared to the required size. To recoil the steel, it is fed through a recoiling machine that winds it back onto a new core or mandrel. Proper tension is applied during this process to ensure a tightly wound coil. Finally, the recoiled steel coil is secured with bands or straps for transportation or storage purposes.

- Q: What are the common methods of handling steel coils during production?

- The common methods of handling steel coils during production include using overhead cranes, forklifts, and coil tongs. These tools are utilized to lift, transport, and position the coils within the production facility. Additionally, coil cars and transfer systems are often used to move the coils between different stages of the production process. It is crucial to handle the steel coils with care to prevent damage and ensure efficiency in the production line.

- Q: How are steel coils used in the manufacturing of automotive exhaust systems?

- Steel coils are used in the manufacturing of automotive exhaust systems as they are formed into specific shapes and sizes to create the necessary components, such as pipes, mufflers, and catalytic converters. The coils are precision-cut, welded, and bent to fit the design requirements and ensure efficient exhaust flow, durability, and resistance to high temperatures and corrosion.

- Q: How are steel coils used in the manufacturing of power generation equipment?

- Steel coils are used in the manufacturing of power generation equipment as they are essential for fabricating components like turbine blades, generator frames, and structural supports. These coils are shaped, cut, and molded into various parts, ensuring strength, durability, and stability in power generation equipment.

- Q: Is a steel plate the same as a steel coil?

- Generally speaking, they can be used interchangeably, and the purchase price of the plate is slightly cheaper.

Send your message to us

Galvanized Steel Coil Dx51d+z CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords