Galvanized Rolled Steel Coils/Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Prepainted Galvanized Steel:

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length, according to the transportation, generally less than 12m

4.color: standard color: red, blue, white, grey; special color: according to RAL color

Specification of Prepainted Galvanized Steel:

Thickness:0.15mm-1.2mm

Width:600mm-1250mm

Coil ID:508mm/610mm

Base Metal: GI/GL.

Zinc Coating:30-275 G/M2

Paint Coating: Top 30; Back 5-7. Or up to Buyer’s Option.

With Protection Film or Without Protection Film.

Spangle: Regular Spangle, Small Spangle, Zero Spangle.

Coil Weight:3-5MT or Customized Weight.

Delivery:15-25 days

MOQ:25MT

Color: RAL Color Series or Customized Colors.

Temper: Commercial Quality G 350; Structural Quality: G550; Full Hard.

Charactics of Prepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, insulation panel, corrugate sheet, facade wall, shutters, T-bar and home appliance.

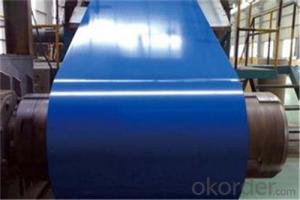

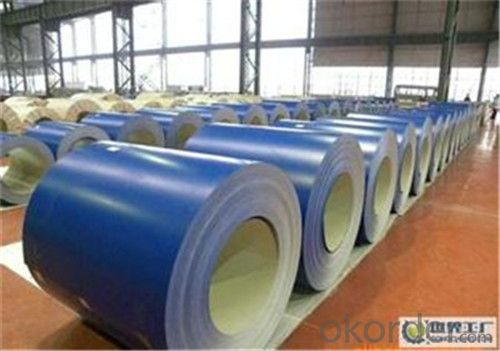

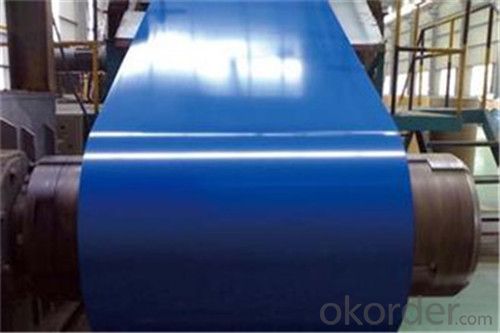

Images of Prepainted Galvanized Steel:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

- Q: What is the average shelf life of a painted steel coil?

- The average shelf life of a painted steel coil can vary depending on various factors such as the quality of paint used, environmental conditions, and storage practices. However, under normal conditions, the average shelf life of a painted steel coil is typically around 1 to 2 years.

- Q: How are steel coils inspected for flatness variations?

- Steel coils are inspected for flatness variations using specialized equipment such as flatness gauges and laser measurement systems. These tools are used to measure the surface profile of the coil, detecting any deviations from the desired flatness tolerance. Additionally, visual inspection and manual measurements by trained professionals are also carried out to ensure accurate assessment of flatness variations in steel coils.

- Q: It seems that steel would be stonger and more stable than wood, fire resistant, and better for the environment, so why are most homes wood-framed rather than steel-framed?

- In most locations a 2x4 is slightly cheaper than a steel stud. The labor is cheaper with wood because it's less skilled and there are many people to swing a hammer cheaply. Most contractors do what they know and most only know wood.

- Q: I have lung cancer. My doctor told me to invest in stainless steel pots to cook with, instead of magnalite. What's the difference between the all stainless steel pots and the Hard-Anodized pots? and are there any stainless steel pots that are nonstick?

- The difference in stainless steel cookware is the amount of different metals used when making them. 18-10 is the best combination. I have Tramontina SS pots and pans and love them. Nice heavy bottoms that evenly heat. Getting used to cooking with stainless is a bit difficult. You need to start with high heat and then turn it down when you add ingredients. This assists in food not sticking.

- Q: What's the length of a coil of cold rolled steel? Is there a standard?

- But in the process of production, not the large volume, a few kilometers long have. The small volume sold by the finished product is much shorter.

- Q: How are steel coils used in the production of steel clamps?

- Steel coils are used in the production of steel clamps as the primary raw material. The coils are fed into a machine that cuts, shapes, and bends them to create the desired clamp design. The strength and durability of the steel coils ensure that the resulting clamps are capable of securely holding objects together.

- Q: How are steel coils used in the manufacturing of crash structures?

- Steel coils are used in the manufacturing of crash structures as they provide high tensile strength and durability, making them ideal for absorbing and distributing impact forces during a crash. These coils can be shaped and formed into various components such as beams, brackets, and panels, which are then integrated into the vehicle's frame or body structure to enhance its crashworthiness and protect occupants in the event of a collision.

- Q: How are steel coils used in the production of wind turbines?

- Steel coils are used in the production of wind turbines to manufacture the tower, nacelle, and other structural components. The coils are processed and shaped into various parts, ensuring the turbines have a sturdy and durable construction. Additionally, steel coils are employed in the manufacturing of the turbine blades, providing strength and reliability to withstand the forces of wind.

- Q: Are steel coils used in automotive manufacturing?

- Yes, steel coils are commonly used in automotive manufacturing. They are used to produce various components such as body panels, chassis parts, and structural reinforcements due to their strength, durability, and formability.

- Q: How are steel coils used in the production of agricultural machinery?

- Steel coils are used in the production of agricultural machinery to create various components and parts such as frames, brackets, and structural supports. The coils are typically cut, shaped, and welded to form these components, providing strength, durability, and stability to the agricultural machinery.

Send your message to us

Galvanized Rolled Steel Coils/Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords