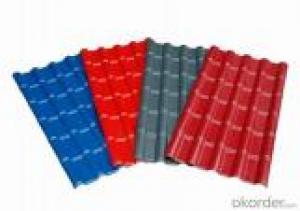

FRP Roofing Sheet of Chemical Resistance Translucent

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Sheet made by serial machinery of FRP sheet have the advantages of smooth surface, even thickness, high impact strength, good weather resistance as well as high productivity. It is the best materials for the surface panels of top grade refrigeration vehicles for its excellent properties of heat and moisture insulaiton.

Thickness:0.8mm、1.0mm、1.2mm、1.5mm、2.0mm、2.5mm、3.0mm;

Width:1000mm、1200mm;

Color:Clear/Lake Blue/Sky Blue/Light Green/ Opal;

Length:30m/rolling

Applications of Chemical Resistance Translucent FRP Roofing Sheet

They are applied to steel structure workshops, warehouses, weather sheds, car parks, weather corridors, lighting sheds, sun sheds,

greenhouses, etc. They are the ideal materials for the choices of enterprises and institutions.

The necessary characters of high quality FRP Corrugated Lighting Sheet:

1. small air bibbles

2. no bubbles

3. anti-aging resin

4. high property upper film(or gelatum)

5. high quality non-alkali fiber-glass

6. consistent high light transmission

7. high chemistry corrosion resistance

8. high anti-ultraviolet property

9. even thickness

Package& Delivery of Chemical Resistance Translucent FRP Roofing Sheet

Wooden pallet,according to custom requires.

Properties of Chemical Resistance Translucent FRP Roofing Sheet

Light transmission

The light transmission of FRP Corrugated Lighting Sheet is between 60-85%. Light through FRP lighting sheet scatters and is mild. It will not form a light band so as to make the indoor brighter.

Weather resistance

The 23μm anti-aging film from Dupont covering on the surface of FRP sheet improves its property of weather resistance. The anti- ultraviolet adsorbing agent mixing in the raw materials absorbs 99.9% of ultraviolet ray of the visible light transmitted through the FRP sheets.This UV protection will help to prevent the dissolution and discoloration of the materials. The unique technology used in FRP Corrugated Lighting Sheet makes the life span of the sheet up to over 15 years, probably 20 years ( a ten-year warranty is supplied).

Impact resistance

The strengthening fiber-glass materials criss-cross the structure of the products,which helps to improve the impact resistance of FRP sheet. When impacted by spalls or hails, they are hardly broken.

Corrosion resistance

The products resist various acids, alkalis and peroxides, especially suitable for application in the coastal areas and corrosive places.

Temperature performance

FRP Corrugated Lighting Sheet is a kind of hot solid high polymer materials. It is designed for normal use in temperatures from - 40℃ to120℃.

Temperature insulation

The coefficient of heat-conduction of FRP Corrugated Lighting Sheet is 0.18kcat / mhr℃ , only 1/4 of the glass. That is why it has a good property of temperature insulation.

Fire-retardant

Fire-retardant the fire-retardant of FRP Corrugated Lighting Sheet is divided into ordinary gradeⅠ and gradeⅡ. The oxygen index of the gradeⅠof fire retardant is ≥32, the grade retardant is ≥26. It meets the standards of the fire brigade department.

Heat stability

FRP Corrugated Lighting Sheet is a kind strengthening plastic of hot solid fiber-glass . Its coefficient of heat expansion is 2.2 x 10-5mm/mm/℃, only 2 times of metal materials. For this reason, when it matches with a metal sheet, the displacement is relatively small, not easy to leak.

- Q: Synthetic resin tile tile for flat slope, in the election when the tile, how to choose?

- Synthetic resin tile tile for flat slope, in the election of the tile, pay attention to the following slightly, to ensure that you choose a good tile

- Q: I heard that synthetic resin tile very environmentally friendly, how an environmental law? How is it done?

- In addition, synthetic resin tile also has the advantages of light weight, waterproof, tough insulation, insulation, noise, anti-corrosion, anti-hail, anti-fouling, fire, insulation, easy installation, etc, is all kinds of permanent building roof decoration and Waterproof ideal material for high-grade roofing materials to provide a more convenient and efficient alternative products, especially for China's current efforts to promote the "Ping-slope" project You call in front of 180 behind 0731 plus the most direct the fastest and most effective

- Q: My house is a resin tile, but the resin tile can only last three decades, three years later how to do it? It makes me depressed

- All the materials are the number of years, the use of commercial housing 40 to 70 years, the scope of application of resin tile is mainly used in flat slope, mobile housing, villas, antique buildings, garden pavilions and other roof areas

- Q: 30 meters long and 9 meters wide house with synthetic resin tile how much money

- Is a resin that combines or exceeds the inherent properties of natural resins

- Q: The difference between the synthetic tile tile roof and the ridge tile and their installation method

- Synthetic resin tile from the height of the ridge, for the different regions are not used, because to prevent the snow after the roof load is too large, the south from the ridge height is small, the north is large

- Q: Is it also used for heat preservation with synthetic resin tiles?

- color retention: in the National Chemical Building Materials Testing Center hours of artificial aging test, synthetic resin tile color change (ΔE) is equal to 223 impact: in the free fall hammer test, 1 kg heavy steel hammer From 15 m height free fall on LCNEST watts, no cracks low temperature resistance: In the freeze-thaw cycle test, after 10 freeze-thaw cycle, synthetic resin tile surface without hollowing, blistering, peeling and cracks and other issues anti-load: in the National Chemical Building Materials Testing Center test, support interval 660mm, increased 150 kg, no cracks damaged heat insulation: synthetic resin tile thermal conductivity of 01Kcal / mh ° C, is steel 1/ concrete 1/12 Fire safety by the National Chemical Testing Center to reach B1 level water resistance: synthetic resin tile surface "SABIC" resin dense non-absorbent, there is no problem of microporous water seepage Installation of a single fast single, extra high efficiency, easy to lift, complete supporting products, the process is simple

- Q: What is the best roof for the supply of high-end villas?

- European-style flat tile is a high-end roof decoration, waterproof products, it is natural natural style, was dedicated to the pursuit of grade villas and various high-grade buildings

- Q: Need anti-corrosion synthetic resin tile, who can provide anti-corrosion synthetic resin tile information to me, to be clear Oh

- 0 parameters Name Specification (Unit mm) 1 Main tile thickness: 30 ± 01 Width: 880 ± 1002 Ridge tile thickness: 30 ± 01 Length: 880 ± 1003 Ramped tile thickness: 30 ± 01 Length: 860 ± 1004 Three-way tile thickness: 30 ± 01 Length: 250 + 200 × 25 Ridge Wrap Head Thickness: 30 ± 01 Length: 240 ± 1006 Length of the eaves tile 250 (Injection Molding) Length 460 (Injection Molding) 7 Plate Length 880 (with W) Width: 880 ± 1008 installation accessories self-tapping nails, protective pad, waterproof cap What is the project you want to do it, Kebao building materials website has a very complete information, you are welcome to search: Kebao building materials In addition can also call one hundred zero zero seven one II zero qi

- Q: Why is the price of synthetic resin tile 3.0 cheaper than 2.0?

- 2 to 14 (20 mm thickness) by weight of about 2

- Q: Synthetic resin tile can be used in what kind of place, residential can use it

- Synthetic resin tile characteristics: one, superior weather resistance; Second, excellent corrosion resistance; Third, excellent anti-load performance; Fourth, the impact of low temperature effect is good; five, self-cleaning; six, easy to install; , Green environmental protection; eight, fire rating to B1

Send your message to us

FRP Roofing Sheet of Chemical Resistance Translucent

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords