FRP High Efficiency FRP Fiberglass Pultrusion Machine on Sale of Various Types

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 150 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

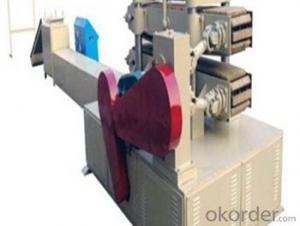

FRP High Efficiency FRP Fiberglass Pultrusion Machine on Sale of Various Types

Product Description:

This production line consists of complete equipments of GRP MP (Glassfiber Reinforced Plastics Motar Pipe) pipe production, from pipe liner making and curing, structural layer making and curing, finishing and grooving and pipe extraction.

Product Features:

1. With high automation in the international. It can save approximately 40% of the worker cost.

2. With high production speed and it is easy to operate. It can increase 50% in production efficiency.

3. Using advanced production process- four dimension. The cost of raw material reduce 30% than traditional production process.

Product Parameter:

Name | FRP High Efficiency FRP Fiberglass Pultrusion Machine on Sale of Various Types |

Brand | CMAX |

Weight | 5T |

Dimension(L*W*H) | 15M*2.5M*3.5M |

Power | 35KW |

Voltage | 380V |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Plates |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Hebei, China (Mainland) |

Color | Selectable |

Warranty | 2 Years |

Time of Delivery | 30-45 days |

Product Pictures:

Our Services:

1.OEM service offered.

2.Engineers available for overseas customer, for machine trial and teaching.

3.Suggest related material and mold for you, turn-key business to save your time.

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be within 45 days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

- Q: The processing of plastic bottles

- Plastic bottle molding is the process of making final plastics from polymers made from synthetic resin manufacturing plants. The processing method (usually called plastic processing) (including compression molding), extrusion (extrusion) and injection molding (injection molding), blow molding (blow molding), rolling, to go through a total pressure plastic, extrusion, injection molding, blow molding, foam molding, calendering, etc. six processes.1 、 pressing and moldingPress molding is also known as molding or pressing, and molding is mainly used for molding thermosetting resins such as phenolic resin, urea formaldehyde resin and unsaturated polyester resin.2. ExtrusionExtrusion, also known as extrusion molding, is the use of extruders (extruders) to heat the resin continuously through the mold extrusion of the desired shape of the product. Extrusion is sometimes also used in the forming of thermosetting plastics and can be used in the moulding of foamed plastics. The advantage of extrusion is that it can extrude various shapes of products. The production efficiency is high, it can be automated and continuous production. The disadvantage is that thermosetting plastics can not be widely used in this process, and the size of products is prone to deviation.3, injection moldingInjection molding is also called injection molding. Injection molding is the use of injection molding machines (or injection machines) to inject thermoplastic melts at high pressure into the mold and to cool and cure the products. Injection molding can also be used for moulding thermosetting plastics and foams. Injection molding has the advantages of fast production, high efficiency, automatic operation, and complicated shape. It is especially suitable for mass production. The disadvantage is that the equipment and mold cost is high, the injection molding machine cleaning more difficult.

- Q: The main plastic of plastic products

- Polyethylene plastics (Polyethylene) are polymers of ethylene monomers. The raw material for production is oil, coke oven gas or alcohol. Industrial production of polyethylene usually by ethanol dehydration, acetylene catalytic hydrogenation or high temperature cracking. Its commodity name is abbreviated as "B plastic"; the English abbreviation is "PE". Because the density of polyethylene is different, it is divided into low-density polyethylene.[PE (L)], medium density polyethylene [PE (M)] and high density polyethylene [PE (H)].The molecular formula of polyethylene is: (- CH2, CH2 -) n. It is linear in geometry and theoretically has no branched chain and is prone to crystallization. Usually the polyethylene molecule is composed of crystalline and amorphous state in high elastic interlaced region; crystalline polyethylene plastic gives high hardness, strength, chemical stability; amorphous region with polyethylene plastic higher flexibility, toughness, transparency etc.. In fact, polyethylene macromolecules are not absolutely free of branched chains. Its crystallinity is different, density is different, physical and mechanical properties are also different.

- Q: profit is not big, about how much investment, please expert advice, mainly to supply the market and small supermarkets

- I just do this, the raw material is used PE, equipment, there are mainly blowing machine, punching machine, if you want to print, then also the printing press, there are other stirring what ah!

- Q: where there are advanced environment-friendly recycled plastic processing equipment?

- Environmental protection recycling plant, this is a systematic project, the use of granulation machine is usually used granulator, need to be matched with waste water filtration, sedimentation, purification treatment pond, waste gas purification equipment.

- Q: What kind of equipment do you need for the food market? How much would you like to invest? What about the profit?

- if 2 more than 20000 more than 20000 color printing, bag making machine semi-automatic, fully automatic ranging from 4-5 million, 3500 mill more than 20000, granulator, raw materials are polyethylene, if the price of raw materials is a new material price 11000 tons, if it is recycled about 7000 of us production of complete sets of equipment

- Q: In Shengze where you can find what rags processed into a plastic factory

- You mean it woven rags! Use a plastic granulator.

- Q: Would like to ask a few questions?1, waste plastics need to go through a few devices or steps to become plastic particles2, how much would it cost for the whole set of plastic particles? (I want to get a small wire first)3, if the equipment, plastic material can be any processing?4, is there any pollution in the whole process?.5, how about this prospect this year?Please have experienced predecessors to give some experience

- The question you ask is too wide. There are too many plastic parts. First of all, you have to decide what kind of plastic you want to make. We usually have PET PP, PVC, PMMA, ABS, PEAnswer the questions you ask first: 1, the most basic, you should have a crusher, washing machine, particle machine2: I'm looking for in our local welders do, that not what technical content, you will not give them to talk about the price, almost tens of thousands of dollars.

- Q: I don't know how much money it needs! Raw materials are used plastic baskets!

- Production of this material, a basic set of machinery and equipment investment of about 70 thousand, if the amount of large, you can choose to configure the machine at around 200 thousand.

- Q: What sewage treatment equipment should be used for waste plastics processing granules?

- Don't be cheap. Environmental protection will only get tighterAfter three months, the water is out of balance

- Q: What equipment? How much money do not.. at first. There are several sets of injection molding machine can be about 2... Mainly plastic injection molding. The ABS PA PE PP PVC... Etc. in this area. Please know that a friend told Kazakhstan. Thank you.

- How big is the product? How big is the injection machine? The machine has been bought. Waste of electricity and high price; the product made by buying small is not good. The injection machine 100 grams may in 6 to 8, in case Taiwan, {brand is not the same, the price difference is very big. } to do PA, if it is enhanced, it is necessary to do special screw and barrel, wear-resistant.

Send your message to us

FRP High Efficiency FRP Fiberglass Pultrusion Machine on Sale of Various Types

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 150 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches