Formwork Speed Shore Kwik Stage System Kwikstage Scaffolding CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Formwork Speed Shore Kwik Stage System Kwikstage Scaffolding

Type:

Material:

Construction Properties:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Place of Origin:

Surface:

Material.:

Thickness:

Descriptions of Formwork Speed Shore Kwik Stage System Kwikstage Scaffolding

Kwikstage Scaffolding is a multi-purpose modular scaffold system which can be used for all forms of access and support structures in the building and construction industries, ship buliding, offshore construction and industrial maintennace.

Details of Metal kwikstage Scaffolding

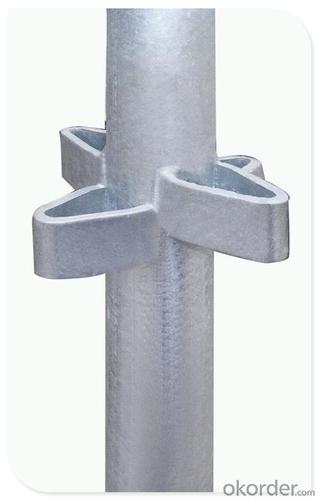

1. Metal kwikstage scaffolding system is a new type of selflock scaffolding which is very popular in Oceanian,African construction.

2. Metal kwikstage scaffolding System is suitable for both inside concrete slab supporting and outside masonry Construction multi-purpose for construction.

3. Metal kwikstage scaffolding systemstandard is weld with a plate every 600mm which can join ledgers at 90 degree.

4. Metal kwikstage scaffolding system ledger is a horizontal member with a blade at each end for insertion into the standard plate.

5. kwikstage scaffolding system is quick to erect and strip which has completely replaced other scaffolding.

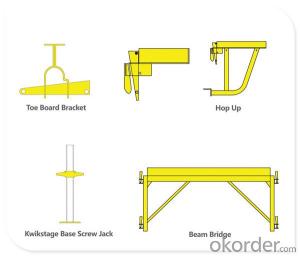

The Accessories of Formwork Speed Shore Kwik Stage System Kwikstage Scaffolding

STEEL STANDARD

Material: steel tube φ48.3x3.25mm

Surface finish: hot dipped galvanized

Standard with normal length 3.0m, 17.02kg

Standard with normal length 2.5m, 14.32kg

Standard with normal length 2.0m, 11.64kg

Standard with normal length 1.5m, 8.94kg

Standard with normal length 1.0m, 6.26kg

Standard with normal length 0.5m, 3.56kg

Topper Standard, 1.72kg

Material: steel tube φ48.3x4.0mm

Surface finish: hot dipped galvanized

Standard with normal length 3.0m, 19.48kg

Standard with normal length 2.5m, 16.38kg

Standard with normal length 2.0m, 13.28kg

Standard with normal length 1.5m, 10.18kg

Standard with normal length 1.0m, 7.07kg

Standard with normal length 0.5m, 3.97kg

Topper Standard, 1.93kg

STEEL LEDGER

Material: Made of steel tube φ48.3x3.25mm

Surface: hot dipped galvanized

Ledger of 3.00m, 13.00kg

Ledger of 2.44m, 10.67kg

Ledger of 2.39m, 10.60kg

Ledger of 1.95m, 8.87kg

Ledger of 1.83m, 8.29kg

Ledger of 1.78m, 8.20kg

Ledger of 1.47m, 6.97kg

Ledger of 1.22m, 5.98kg

Ledger of 1.05m, 5.31kg

Ledger of 0.71m, 3.97kg

TRANSOM (ANGLE)

Material: Made of steel 5# angle

Surface: hot dipped galvanized

Transom 2.39m, 17.71kg

Transom 1.78m, 13.60kg

Transom 1.27m, 10.19kg

Transom 1.22m, 9.85kg

Transom 1.05m, 8.70kg

Transom 0.813m, 7.12kg

Transom 0.71m, 6.42kg

Transom 0.60m, 5.75kg

Transom 0.51m, 5.08kg

L/A Transom 1.8m, 11.78kg

L/A Transom 1.2m, 9.56kg

BRACE

Material: Made of steel tube φ48.3x3.25mm

Surface: hot dipped galvanized

Brace 3.6m, 15.33kg

Brace 3.2m, 14.00kg

Brace 2.7m, 12.25kg

Brace 2.0m, 9.33kg

Brace 1.6m, 7.99kg

STEEL PLANK

Material: Made of 1.8mm thickness pre-gal.steel sheet

Surface: hot dipped galvanized

Size: 229mm(W)x 66mm(H)

Steel Plank 4.00m, 25.30kg

Steel Plank 3.00m, 18.90kg

Steel Plank 2.44m, 15.37kg

Steel Plank 2.00m, 12.52kg

Steel Plank 1.81m, 11.42kg

Steel Plank 1.25m, 8.20kg

Steel Plank 1.05m, 7.05kg

Steel Plank 0.736m, 5.25kg

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: What is a bowl buckle scaffold?

- The buckle type multifunctional scaffold is a new type scaffold which is developed on the basis of absorbing the advanced joint and fittings of the same type of scaffold in foreign countries and combining with the actual situation of our country.

- Q: I plan on playing tennis and doing track and field at school... Im getting the piercing this month and it won't be healed in time to take it out. How can I conceal it or possibly even help it heal faster??

- Why no longer enable your ear pieced lower back while you're off out of your prepare like in case you have a much better than one week holiday so which you do no longer could desire to get rid of and placed your jewelry many of the time. a minimum of you could evade preserving your ears many of the time and evade the an infection. you could enable your ears heal ideal. in case you could no longer wait to have your ear pierce lower back once you get rid of and placed decrease back your jewelry make it beneficial you sanitized your palms by skill of washing and employing alcohol. placed Neosporin (antibiotic ointment) on your new pierced jewelry and on the jewelry itself in the previous putting it decrease back. in the previous additionally they use medicated string or thread on the ears for the piercing of latest child toddlers.

- Q: Want to rent the scaffolding in the county, you need to cast how much money

- Look what you want to do. Store rent is not.

- Q: According to the standard set up double scaffolding scaffolding to the number of meters per square meter

- The span, the rod step is easy to calculate, I have done the program in general 4.4.8 meters

- Q: What are the common rules for calculating the amount of scaffolding works

- According to the wall masonry scaffolding (single) vertical projection area calculation with square metre.Scaffolding, without deduction of door and window opening, air ring, vehicle channel, deformation joint area. At the same time, the height of the same building is different, according to the vertical height of the building.

- Q: What is the meaning of the scaffold when it is set up in the concrete structure of the permanent building

- . Among them, the specification of the steel pipe is from 0.5m to 6m, and the fastener mainly has a rotating shaft, a cross and a joint fastener. Bowl buckle scaffold also uses Phi 48, 3.5 wall thickness steel

- Q: What heights do u need a harness for(had to repost as didnt explain correctly in last 1)

- OSHA says that you need guardrails, safety nets or a fall-arrest system if you're working or walking near an unprotected surface more than 6' above a lower level.

- Q: Because my friend wants it done but isn't sure :)

- In all honestly, I'd try to talk your friend out of getting that hip piercing. Surface piercings, especially one there, Will reject. I don't mean to sound negative, but have her put two dots where she would want the piercing, and move around as she does daily, she will see how much that area moves. The more movement = the less likely it will heal. They could reject after a month, they could reject after two years. It really depends. No matter how well the piercer, or how well she takes care of it, it will reject. I went to the best piercers in state to get my surface work (sternum, nape) done. I also took care of it by doing sea salt soaks once or twice a day. When that didn't work I used the LITHA (leave it the hell alone) method.The sternum rejected in six months, where the nape was doing great up until that two year mark. Then it started rejecting. If you want to see what a rejecting piercing looks like feel free to send me an Email, I have some pics of my sternum piercing early on - when it started rejecting, then a day or two before I took it out. It honestly looked horrible that few days before I took it out. The piercing place I go to won't do surface piercings on minors, so you have to be 18 for that one in Minnesota. For the scaffold/industrial, you have to be 16 with parental consent and 18 without in the United States.

- Q: i was thinking of having it done. google it if you don't know what it looks like. but i can't handle pain too well, and as i've seen on youtube, its not nice lmfao, i know pain varies from person to person, but any ideas on how to like take your mind off it? im quite young and this is my first major piercing, i only have my lobes done twice;), and does anyone know a good place to find nice barbells once it's healed:)? thanks:)!aaand do you think this is a nice piece to put in once its healed?

- Actually getting it pierced isn't all that painful, it's the couple of weeks after that might hurt...but as long as it's looking after properly (cleaned every day) all should be good. Sleeping on it can be painful, so i would suggest you get the side pierced that you don't usually sleep on. As for taking your mind off it, maybe take someone in with you while you get it done? then you can either talk to them to distract you or just squeeze their hand...also try not to look at the needle as this could just scare you, don't worry too much though, it'll all be over and done with in a few seconds and the pain really isn't that bad. As well as making sure you clean it every day, it's also important to make sure you're not playing with/touching it all the time as this could lead to an infection, always make sure your hands are clean before touching it. That industrial bar looks really nice, i would aim on waiting a couple of months before putting it in though maybe even about 4-5 months. Overall i think you should defiantly get it pierced the look really nice, good luck!! :)

- Q: Cantilever scaffold technical disclosure Find satisfaction free speed!!!

- 1, steel pipe:(1) the steel pipe shall have the product quality certificate and inspection report with the outer diameter of 48mm and the thickness of 3.5mm of the steel pipe welded to the steel pipe of 3. Rust must be replaced, not to be used to build the frame.(2) the surface of the steel pipe shall be straight and smooth, and shall not be used for cracks, scars, delamination, dislocation, hard bending, burrs, indentation and deep drawing.(3) anti rust paint for steel pipe. Vertical rod and bar brush yellow rust proof paint, scissors and handrails with red and white tube brush. The maximum quality of each steel pipe shall not be greater than 25Kg. Steel pipe is strictly prohibited.

Send your message to us

Formwork Speed Shore Kwik Stage System Kwikstage Scaffolding CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords