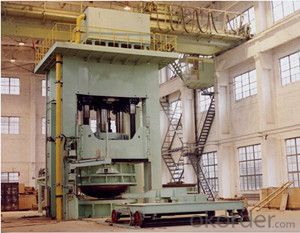

Forging Equipment Steel Pipe & Bar Straightening Press

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TYHI’s steel pipe and bar straightening hydraulic presses are mainly used for straightening large-diameter pipes and bars. There are two structures, i.e. vertical straightening and horizontal straightening. We produce 5MN, 8MN, 10MN, 12.5MN, 20MN and 25MN models.

We also design and manufacture corresponding pipe and bar straightening hydraulic presses per customers’special requirements.

Our main products include lifting equipment, forging equipment, rolling equipment, excavation equipment, coke oven equipment, coal chemical equipment, wind power generating equipment, oil film bearings for rolling mills, gear drive equipment, train wheels and axles, forgings and castings and project contracting.

Our key products include our 1200t EOT crane, our 500t ladle crane, our 75m³ shovel for mining, our Φ180mm continuous rolling production line, our 110 MN aluminum alloy extrusion press and our 7m top charging coke oven equipment.

TYHI’s products are widely used in the metallurgical, mining, energy, transportation, aerospace, chemical, rail, ship building, environmental protection and various other industries. Many products designed and manufactured by TYHI have filled gaps in the domestic market. Furthermore, we have created 360 nationally and internationally recognized products which have been exported to approximately forty countries and regions.

TYHI is now delving further into the development of the rail, engineering machinery, new energy, and maritime equipment fields. We have established a new production base in the Binhai New Area of Tianjin to facilitate the transportation and export of large-sized equipment. Our second wheel production line is currently under construction. We have also established production lines for wheels, axles and wheel sets for use at speeds above 200 km/h.

We are now turning our focus to international markets which we are certain can benefit from our high quality products and service. As we are constantly innovating and improving, we have no doubt that we will meet and even exceed our customers’ expectations.

- Q: The word punch how to make sentences

- Huge dynamic stresses can occur in structures such as bridges, inverted siphons, machine bases, presses and so on.

- Q: The connector socket plug is operated by what punching machine

- Like the phone, camera, computer, socket plug connector are precision high-speed punching machine to press the metal into a specific shape, and then injection molding or direct installation!

- Q: How to distinguish between stamping machine installed mold to pad pad it?

- Measure the minimum size of the punch slam bottom to the work surface

- Q: What is the principle of the punch clutch?

- Between the connecting rod and the slider between the need for circular motion and linear motion of the transfer point, the design of roughly two kinds of institutions, one for the ball, one for the pin (cylindrical), through this body will be circular motion

- Q: Does anyone know that Taiwan is doing punching company which is more famous?

- Hello, very honored to answer your questions.

- Q: How do novices use stamping machines?

- 2. Before the official operation by the idle test, to confirm the normal part of the work before the work.

- Q: Punch infrared sensor and machine how to get together

- Infrared, also known as infrared light, it has reflection, refraction, scattering, interference, absorption and other properties.

- Q: Punch, punching machine, presses in the processing of any difference

- Punch and punching machine should be the same thing, referring to the same thing, but the argument is different.

- Q: Hydraulic press is generally not suitable for punching process, why

- But the hydraulic press is much more stable than the press.

- Q: 110t stamping machine noise is how much decibel

- 110 tons of punch noise and continuous noise, the main factory factory can only detect the air run when the noise figure,

Send your message to us

Forging Equipment Steel Pipe & Bar Straightening Press

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords