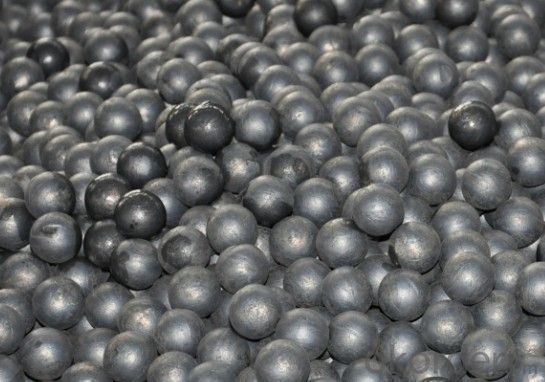

Forged Grinding Media Steel Balls With High Hardness and Resistance, Top Quality For Cement and Mine

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 20000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Forged Grinding Media Steel Balls With High Hardness and Resistance, Top Quality For Cement

and Mine:

1. Diameter:20mm-150mm(0.75''-6'')

2. Surface Hardness:

Forged ball:58-65HRC

Casted ball:60-65HRC

3. Material:

Forged ball: Steel

Casted ball: Iron

4. Technology: Forged & Casted ,heat treated

5. Unbreakable:0.5 Max.

6. Impact Toughness:>12

7. times of falling ball:5000 min.

8. microstructure: P+C

9. Application: gold & iron mine, steel works, cement plant and power station

10. Certificate: ISO9001:2008

Features of Forged Grinding Media Steel Balls With High Hardness and Resistance, Top Quality For Cement

and Mine:

1. High hardness

2. Good wear resistance

3. High toughness

4. No mal-roundness

Chemical Composition of Forged Grinding Media Steel Balls With High Hardness and Resistance, Top Quality For

Cement and Mine:

Name | C | Mn | Si | Cr | S | P | |||

60Mn | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | 0.25max | 0.035max | 0.035max | |||

65Mn | 0.60-0.70 | 0.90-1.2 | 0.17-0.37 | 0.25max | 0.035max | 0.035max | |||

75MnCr | 0.70-0.85 | 0.70-0.85 | 0.17-0.37 | 0.40-0.60 | 0.030max | 0.030max | |||

Specification of Grinding Media Ball | |||||||||

Nominal diameter | Diameteical Tolerance | Weight of single ball in average | Surface hardness | Impact toughness | |||||

(mm) | (mm) | (g) | (HRC) | (j/cm2 ) | |||||

Φ20 | +2 -1 | 32 |

55-65 |

≥12 | |||||

Φ25 | 64 | ||||||||

Φ30 | 110 | ||||||||

Φ40 | 263 | ||||||||

Φ50 | 513 | ||||||||

Φ60 | +3 -2 | 888 | |||||||

Φ70 | 1410 | ||||||||

Φ80 | 2104 | ||||||||

Φ90 | 2996 | ||||||||

Φ100 | 4110 | ||||||||

Φ110 | +4 -2 | 5457 | 50-60 | ||||||

Φ120 | 7102 | ||||||||

Φ130 | 9030 | ||||||||

Φ140 | +4 -3 | 11278 | |||||||

Φ150 | 13871 | ||||||||

| |||||||||

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- Yantai five God casting is generally 53 yuan /kg, the appearance is quite beautiful

- Q: Why does the precision casting factory not usually make iron castings?

- Jiangyin Lin Xing stainless steel (precision manufacturing) Co., Ltd. to provide professional precision casting

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- Good welding of low carbon steel (alloy), probably because the weld workpiece rigidity, fast cooling, the weld internal crystallization of brittle microstructure (martensite), so after welding or welding process welding using self heat, reasonable arrangement of weld, welding seam and heat affected zone heat treatment. The welding heat treatment is often used to preheat before welding, after welding withasbestos cloth covering slow cooling annealing, reach the purpose, its main function is to reduce the internal stress, improve the weld microstructure of martensite formation, reduce brittle tendency, preventing welding cracks.

- Q: What method of casting does not rust? I think the sample is like oil

- The surface of a general casting is easy to rust. In order to prolong the rusting period, antirust paint or antirust oil is usually sprayed. What you said should be anti rust oil.

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- If it is not directly cast hole hole, later processing, large pores may be directly cast out,

- Q: What should I pay attention to when designing a casting structure?

- The basic structure of unit 3 in the design of metal casting casting and its parameters are selected, usually should also pay attention to: (1) because of the metal type heat quickly, so the metal type casting minimum wall thickness should be bigger than the sand casting casting casting; (2) the inner wall of the internal ribs and the thickness of a should be connected the outer wall thickness of 0.6 to 0.7, or as the inner wall (rib) cold slowly, cracks in the wall at the junction in the casting shrinkage; (3) to prevent generating white grey cast iron, in addition to taking measures in the process, must make the wall thickness is not too thin (some information that cast fillet at the corner of the wall thickness of 15mm or more, with metal casting casting must be in the corner, for Aluminum Alloy, metal casting magnesium alloy castings shall not be less than 3 ~ 4m; (4) because of the metal type and the core that, for To facilitate the extraction of castings and casting out type, slope casting should be suitably large than sand casting metal casting, the general should be 30% ~ 50%, it should be pointed out that in addition to the height of the slope of casting size and alloy type, wall, is also related to the casting surface position, where the cooling and contraction of the metal type the surface of casting surface can be designed from the tendency of small inclination, while casting shrinkage tend to be pressed on the surface of metal casting type should be given greater inclination.

- Q: Cause of choking of casting parts

- Is it boiling from the picture? Does it sound like a fire? If not, it's not choking. I feel like choking. The gas doesn't drain out

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q: What kind of flaw detector is better for casting parts?

- If you want to detect internal defects, you can use ultrasonic flaw detector, ray flaw detector can also, but the ray of the safety protection level is too high, not recommended priorityMacro Xu flaw detector answered, such as the magnetic particle inspection machine has the demand can contact us, Baidu "macro Xu flaw detection""

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- If is casting, internal shell mold may be not completely dry, strength is not enough, resulting in shell mold collapse into molten steel.It is also possible that the refractory is not refractory enough.

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2000 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | Domestic Market, South Asia, Southern Europe, Northern Europe, Central America |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Balls; Grinding Rods; Grinding Cylpebs. |

| Product Price Range | Average |

Send your message to us

Forged Grinding Media Steel Balls With High Hardness and Resistance, Top Quality For Cement and Mine

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 20000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords