Wilsonart Food Grade Aluminum Sheet Pop Up Foil Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

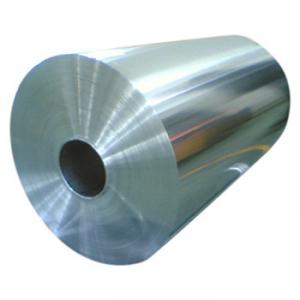

1.Structure of Food Grade Aluminum Sheet Pop Up Foil Sheets Description:

Aluminium foil is an absolute barrier to light, oxygen, gases, moisture, bacteries and provides high level of protection, preservation, conservation of products characteristics for long period of time and without refrigeration.Thanks to its barrier properties, its light weight and its infinite recycling possibilities, aluminium foil in food and beverage applications saves more resources than what it needs for its production. Thanks to effective protection and appropriate format, Aluminum Foil packaging helps to prevent spoilage and waste of valuable food, the production of which requires significantly more resources than the production of its packaging

2.Main Features of Food Grade Aluminum Sheet Pop Up Foil Sheets :

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

3. Food Grade Aluminum Sheet Pop Up Foil Sheets Images:

4. Food Grade Aluminum Sheet Pop Up Foil Sheets Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: General characteristics of pure aluminium plate of pure aluminium plate

- I really want to know to call 1362889760 for your reference as follows: according to the content of different aluminum alloy elements can be divided into 8 series respectively 1***, 2***, 3***, 4***.5***.6***.7***.8*** according to the different processing technology can be divided into cold and hot rolling. They can be divided into thin plate and medium plate according to their thickness. GB/T3880-2006 standard specifies a thickness of 0.2 millimeters, called aluminum foil. More commonly used grades: pure aluminum plate, 1060 plate. Foil. Thick plate, tensile tube. Extruded tube. Type. Bar. Cold processing bar mainly for corrosion resistance in forming of high places, but not of high strength components, such as chemical equipment, marine equipment, railway tanker, conductive materials, instruments and materials, electrode etc.. 3003: plate, strip. Foil. Thick plate, tensile tube. Extruded tube. Type. Bar. Wire rod。 Cold bar, cold wire, rivet wire, forging, foil, heat sink material mainly used for processing requires good molding property, high corrosion resistance, good weldability or parts, or both have these properties need than the workpiece of 1*** alloy with high strength, such as the transport of fluids tank and tank, pressure tank, storage device, heat exchanger, chemical equipment, aircraft fuel tank, oil pipe, reflective panels, kitchen equipment, cylinder washing machine, rivet, wire. 3003 aluminum alloy sheet, plate, tube drawing. Extruded tubes, houses, partitions, roof covers, piping, etc. 3004 plates, thick plates, tensile tubes.

- Q: Are aluminum sheets easy to clean?

- Yes, aluminum sheets are generally easy to clean due to their smooth surface and non-porous nature, allowing for easy removal of dirt, grease, and stains with regular cleaning agents.

- Q: Curtain wall aluminum plate reinforcement spacing between the number of appropriate, the country has no standard?

- As to the stiffener of the aluminum veneer, what are the following points?:1, aluminum reinforcement spacing is generally around 600mm, in order to ensure the aluminum plate in the positive and negative pressure conditions within the scope of deformation. When aluminum plate is welded, there is internal stress due to welding deformation (this internal stress can not be completely eliminated for a long time), and the rigidity of reinforcing bar should also be increased.2. The sectional dimension and spacing of stiffeners shall be determined according to the calculated wind pressure of the aluminum plate. But it is worth noting that the reinforcement calculation of single aluminum plate strengthening is different from the glass curtain wall, first, its strength is certainly no problem (still not seen the wind blowing broken plate, there is no joke) deflection possibility, bend off and windy weather also very few people to pay attention to the single aluminum plate plate surface after deformation the scenery. Therefore, the calculation of deflection of stiffeners are considered under the condition of wind strength and deflection when the winds of aluminum can cause permanent plastic deformation.In fact, aluminum veneer manufacturers generally use the single aluminum plate edge folding groove made of aluminum and 20*40*20, installed in the distance about 600mm. Also useful for profile (grooved aluminum) stiffenersThe spacing between stiffeners is very important to the cost of production. Generally speaking, the spacing of stiffeners will be changed from 600 to 350, and the cost will be increased by 8~15 yuan / square meter

- Q: Hi,I'm building a tricycle for 2 passengers as well as the rider.My main concern for the structure of the chassis is the junction between the rear and the bike frame. Both structures on their own withstand the weight when made out of aluminium, no need to go for steel. But what about that junction? Will aluminium have a propensity to buckle? should i used double tubing or a fork design? I suppose the shape and caliber of the tube also comes into play.Lastly, which of a tube or cylindrical rod is stronger?ThanksAddendum: I'm looking at aluminium because it's cheaper and for weight reduction in the vehicle.

- ehter one may work well depending on what the wheel base is but i prefer steel as it is easyer to weld and and a gusset or two if you need to. aluminum can be hard to weld and un forgiving if you make a misstake.

- Q: This question asks if there are distinctions among various coatings applied to aluminum sheets.

- <p>Yes, there are significant differences between different types of coatings on aluminum sheets. These differences can include the purpose of the coating, such as for corrosion resistance, decorative effects, or enhanced durability. The materials used for the coatings can also vary, with options like anodizing, powder coating, or paint. Each type of coating has unique properties, such as resistance to weather, chemicals, or UV rays, and they can affect the surface appearance, weight, and cost of the aluminum sheet. The choice of coating often depends on the specific application and environmental conditions the aluminum sheet will be subjected to.</p>

- Q: What is the most efficient and low cost method for welding 1mm-3mm aluminum sheet?,What's new?

- If the cost is low, or belongs to the welding; and to stress the process of words, or to inert gas welding (TIG or MIG), and can use tungsten arc alternating current arc welding or tungsten arc argon arc welding.

- Q: has aluminum sheet reacted with concentrated sulfuric acid?

- it can be regarded as no reaction, concentrated sulfuric acid will make aluminum's surface inactivation,and produce a layer of dense aluminium oxide film which will prevent further reaction.

- Q: Hi, I'm new here. Yoroshigu.I'm trying to make flash paper for magic tricks.To do that I have to make flash powder but in my location I can hardly find ingredients. Not to think about buying. Usually, I wait for a season and buy firecrackers. Then, I take the power and soak them into the paper and dry. This works but not so flash. Burned more likely.So, I wonder if I take aluminium oxide from aluminium oxide sandpaper and mix with powder from firecracker would produce a brighter flash than firecracker power alone?anyone know please share.

- You should set this project aside. Ignore my advice? You're on track for a Darwin Award. You win!

- Q: Is it possible to substitute aluminum sheets for wood siding in construction?

- <p>Yes, you can use aluminum sheets to replace wood siding. Aluminum siding is a popular alternative to wood for several reasons. It is lightweight, durable, and resistant to rot, insects, and moisture. It also requires less maintenance than wood and can be painted to match various aesthetic preferences. However, it's important to consider factors such as insulation properties, cost, and the look you want to achieve, as aluminum may not perfectly mimic the appearance of wood. Always consult with a professional to ensure proper installation and compatibility with your home's architecture.</p>

- Q: Is it possible for an individual to install their own aluminum sheet roofing?

- <p>Yes, you can install your own aluminum sheets roof, but it requires some skills and knowledge. You'll need to measure and cut the sheets accurately, secure them properly, and ensure watertight installation. It's advisable to have experience in roofing or construction, or to follow detailed instructions and safety precautions. For complex roofs or if you're unsure, hiring a professional is recommended to avoid damage or injury.</p>

Send your message to us

Wilsonart Food Grade Aluminum Sheet Pop Up Foil Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords