Flat Wire Steel Mild Slitting China Prime Quality Carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Flat Wire Steel Mild Slitting China Prime Quality Carbon at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Flat Wire Steel Mild Slitting China Prime Quality Carbon are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Flat Wire Steel Mild Slitting China Prime Quality Carbon are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Size | Width | Tolerance | Thickness | Tolerance |

20 | 20 | +0.5 -1 | 2-4 | +0.3 -0.5 |

22 | 22 | +0.5 -1 | 2-4 | +0.3 -0.5 |

25 | 25 | +0.5 -1 | 2-6 | +0.3 -0.5 |

28 | 28 | +0.5 -1 | 2-6 | +0.3 -0.5 |

30 | 30 | +0.5 -1 | 2-6 | +0.3 -0.5 |

32 | 32 | +0.5 -1 | 2-6 | +0.3 -0.5 |

35 | 35 | +0.5 -1 | 2-6 | +0.3 -0.5 |

40 | 40 | +0.5 -1 | 3-6 | +0.3 -0.5 |

45 | 45 | +0.5 -1 | 3-6 | +0.3 -0.5 |

50 | 50 | +0.5 -1 | 3-6 | +0.3 -0.5 |

55 | 55 | +0.6 -1.3 | 3-6 | +0.3 -0.5 |

60 | 60 | +0.6 -1.3 | 3-6 | +0.3 -0.5 |

65 | 65 | +0.6 -1.3 | 3-10 | +0.3 -0.5 |

70 | 70 | +0.6 -1.3 | 3-10 | +0.3 -0.5 |

75 | 75 | +0.6 -1.3 | 3-10 | +0.3 -0.5 |

80 | 80 | +0.9 -1.8 | 3-10 | +0.3 -0.5 |

85 | 85 | +0.9 -1.8 | 6-10 | +0.3 -0.5 |

90 | 90 | +0.9 -1.8 | 6-10 | +0.3 -0.5 |

95 | 95 | +0.9 -1.8 | 6-10 | +0.3 -0.5 |

100 | 100 | +0.9 -1.8 | 6-12 | +0.3 -0.5 |

105 | 105 | +1 -2 | 6-12 | +0.3 -0.5 |

110 | 110 | +1 -2 | 6-12 | +0.3 -0.5 |

120 | 120 | +1 -2 | 6-20 | +0.3 -0.5 |

125 | 125 | +1 -2 | 6-20 | +0.3 -0.5 |

130 | 130 | +1 -2 | 6-20 | +0.3 -0.5 |

140 | 140 | +1 -2 | 6-20 | +0.3 -0.5 |

150 | 150 | +1 -2 | 6-20 | +0.3 -0.5 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

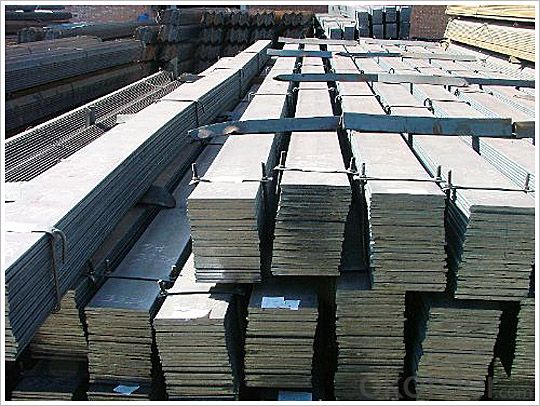

Images:

- Q: How do steel flat bars contribute to the overall durability of commercial structures?

- Steel flat bars contribute to the overall durability of commercial structures by providing strength and stability. They are commonly used in construction to reinforce concrete structures, such as beams and columns, and to support heavy loads. The high tensile strength of steel makes it resistant to bending and breaking, ensuring that the structure remains stable and can withstand various environmental and structural stresses. Additionally, steel flat bars are corrosion-resistant, making them ideal for withstanding harsh weather conditions and extending the lifespan of the commercial structure.

- Q: Can steel flat bars be used for creating architectural facades or cladding?

- Yes, steel flat bars can be used for creating architectural facades or cladding. Steel is a versatile and durable material that can be shaped and manipulated to create various architectural elements. Steel flat bars can be used to create sleek and modern architectural facades or cladding, providing a clean and contemporary aesthetic to buildings. The flat bars can be cut, welded, and installed in different configurations to achieve different design patterns and textures. Additionally, steel is known for its strength and resistance to weathering, making it an ideal choice for exterior applications. Overall, steel flat bars offer a wide range of design possibilities and can be effectively used to create striking architectural facades or cladding.

- Q: Can steel flat bars be hardened or tempered?

- Steel flat bars can indeed undergo hardening or tempering. Hardening entails heating the steel to a specific temperature and rapidly cooling it, typically through water or oil quenching. This procedure alters the steel's molecular structure, resulting in heightened hardness and resistance against wear and deformation. Conversely, tempering takes place after hardening and involves reheating the steel to a lower temperature, followed by slow cooling. This step aids in alleviating internal stresses and enhancing the steel's toughness and ductility, rendering it less brittle and more suitable for certain applications. To achieve desired mechanical properties, both hardening and tempering can be employed on steel flat bars. It is important to note, however, that the particular hardening or tempering method and parameters may differ depending on the type of steel utilized and the desired outcome.

- Q: Do steel flat bars have a specific tolerance range?

- Yes, steel flat bars do have a specific tolerance range. Tolerance refers to the acceptable deviation from the specified dimensions or properties of a product. In the case of steel flat bars, the tolerance range typically includes variations in thickness, width, and length. The specific tolerance range may vary depending on the manufacturing standards, grade of steel, and intended application of the flat bars. These tolerances are important to ensure the flat bars meet the required specifications and can be effectively used in various construction and industrial applications.

- Q: Can steel flat bars be used in the construction of buildings?

- Indeed, buildings can be constructed using steel flat bars. Owing to their robustness, endurance, and adaptability, steel flat bars are frequently employed in construction. They offer structural reinforcement and are commonly utilized for framing, reinforcement, and support systems within buildings. Steel flat bars can be conveniently fashioned, welded, and molded to fulfill the precise demands of a construction endeavor. Furthermore, they possess resistance against corrosion, fire, and pests, rendering them an excellent option for constructing enduring and robust buildings.

- Q: Can steel flat bars be used in the manufacturing of medical equipment?

- Yes, steel flat bars can be used in the manufacturing of medical equipment. Steel is a versatile material that offers several beneficial properties for medical equipment applications. It is known for its strength, durability, and resistance to corrosion, making it suitable for withstanding the rigorous demands of medical equipment usage. Additionally, steel flat bars can be easily shaped, welded, and machined to meet the specific requirements of different medical equipment components. This makes steel flat bars an ideal choice for manufacturing various medical instruments, such as surgical tools, orthopedic implants, dental equipment, and hospital furniture.

- Q: What are the common methods of surface cleaning for steel flat bars?

- There are several common methods for surface cleaning steel flat bars: 1. Mechanical Cleaning: This method involves the use of abrasive materials such as wire brushes, sandpaper, or abrasive pads to physically scrub and remove dirt, rust, or other contaminants from the surface of the steel flat bars. This method is effective for light to moderate cleaning and can be done manually or with the help of power tools. 2. Chemical Cleaning: Chemical cleaning involves the use of various cleaning agents or solvents to dissolve and remove dirt, grease, oil, or other stubborn contaminants from the surface of the steel flat bars. These cleaning agents may include alkaline or acidic solutions, degreasers, or specialized steel cleaners. It is important to follow the manufacturer's instructions and safety guidelines when using chemical cleaning agents. 3. Pickling: Pickling is a method often used to remove heavy rust or scale from the surface of steel flat bars. It involves immersing the bars in an acidic solution, typically a mixture of hydrochloric acid and water, which dissolves the rust or scale. After pickling, the bars are rinsed thoroughly to remove any remaining acid and then dried. 4. Sandblasting: Sandblasting uses compressed air to propel fine abrasive particles, such as sand or steel grit, at high speeds onto the surface of the steel flat bars. This method is highly effective for removing heavy rust, scale, or old paint coatings. It creates a roughened surface that promotes better adhesion for subsequent coatings or finishes. 5. Electrochemical Cleaning: Electrochemical cleaning, also known as electrolysis or electrocleaning, involves using an electric current to remove rust or other contaminants from the surface of the steel flat bars. The bars are immersed in an electrolyte solution, and the electric current causes the rust to dissolve, leaving a clean surface. This method is often used for delicate or intricate surfaces where mechanical methods may cause damage. It is important to select the appropriate cleaning method based on the level of contamination, type of surface, and desired end result. It is also crucial to follow proper safety procedures and wear personal protective equipment when performing surface cleaning on steel flat bars.

- Q: Are steel flat bars suitable for food processing applications?

- No, steel flat bars are not suitable for food processing applications. Stainless steel is the preferred material for food processing due to its corrosion resistance, hygienic properties, and ease of cleaning.

- Q: What are the standard packaging options for steel flat bars?

- The standard packaging options for steel flat bars typically include bundling them with steel straps or wrapping them in protective material such as plastic or paper, to ensure safe transportation and prevent damage or corrosion.

- Q: Can steel flat bars be cut to length?

- Certainly! It is possible to cut steel flat bars to the desired length. These bars possess great versatility, and one can easily cut them using a range of cutting tools like saws, shears, or plasma cutters. Typically, fabrication shops or construction sites carry out this process to fulfill specific project needs. By employing proper tools and techniques, steel flat bars can be precisely and neatly cut to the desired length.

Send your message to us

Flat Wire Steel Mild Slitting China Prime Quality Carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords