Flat hacksaw Frame with Wooden Handle SJ-0130

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

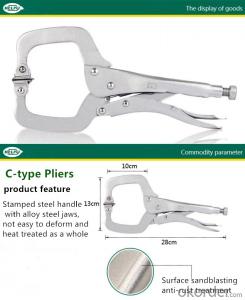

Metal Hacksaw Frame

1.Metal handle

2.Square tubular.heavy duty.

3.Size:30"

4.Packing:polybag packin

Adjustable saw frame:8"/10"/12",

surface treadment:chrome plating, plastic spraying, corrosion resistance,with non-slip handle.

Saw blade:18TPI,carbon steel product whole steel structure, with non-slip handle. Can cut steel, wood, plastic stool rod type, durable

Our Services

1.Well-trained and experienced staffs to answer your enquirers within 24hrs.

2.OEM&ODM or customized tools are available.

3.We have strict test and QC system to guarantee the high quality.

4.Track the order until you get the goods.

We can supply the sampe for inspect,but the sample cost and freight paid by customers

We have a special team for oversea marketing service,if there is any query,please feel free to contact with us.

- Q:What machine saw? Wood saw is smooth and not polished

- At present, the technology has not such a saw, which is caused by its working principle, the interval of the local employment saw wood, to saw body not be clamped and staggered sawtooth, which saw a road section on the sawn wood. In contrast, the fine teeth are smaller than the rough teeth. But it must not be as smooth as cutting meat.

- Q:You can cut off the alloy steel hacksaw

- Generally speaking, you can. But to see what alloy to see his hardness, if you can cut off below HRC60, if more than 60 cannot be cut down, because the blade hardness is HRC60.

- Q:What brand of gasoline (petrol saws, felling saw) better? How much is the price?

- But the import chainsaw has his advantage, Steele saw more fuel-efficient. More than twenty-five percent of oil savings. The main features of Japanese Komatsu chainsaw is the comfort of the machine. It's better than too many other machines.

- Q:What type of saw blade is used to cut the fireproof board

- Fireproof board is the impregnation process of base paper (titanium powder, paper and kraft paper) through melamine and phenolic resin, which is made by high temperature and high pressure. So in the sawing fire board is melamine board type, usually with a professional panel saw, saw blade for cutting board professional. Commonly used are two specifications of the saw blade, one is 12 inches, 72 teeth, one is 12 inches, 96 teeth of the saw blade, all choose flat teeth. With the use of the saw blade, so that it will not collapse, and the section is very smooth.

- Q:What kind of saw blade is used for sawing wood lines?

- It is recommended to use plain saw frames in carbide saw blades, 255*3.0*30*120, i.e., 255MM outer diameter, 3.0MM blade thickness, 30mm inner diameter, 120 teeth. The cutting aluminum saw blade is different from the cutter head at first, and the tooth shape is different.

- Q:What brand of electric chain saw is good?

- MAKITA can, we will use the sub site tree is MAKITA, gold house electrical city there is a sale.

- Q:Woodworking, DIY power tools, curve saws and circular saws, which is more practical?

- You need a good saw and a backer to see it straight, but this is also relative. It must not be better than the circular saw. You may have to buy two or so as to make the best use.

- Q:Cutting technique for concrete cutting

- Diamond rope saw cutting machine hydraulic sawing machine, hydraulic disc (aka hydraulic wall saw cutting machine), electric wall saw cutting machine, cutting machine, hand chain road cutting machine, cutting machine, diamond drill the large ultra-high pressure water cutting machine cutting equipment, high pressure water cutting machine (also known as: the cost of construction and expensive. The market has not yet widely used) and other equipment on the concrete cutting construction.

- Q:What oil can be used instead of the saw mixture?

- Chain saws require gasoline, engine oil, and chain saw lubricants:Petrol can only be used with unleaded gasoline no more than 90. When adding gasoline, the fuel tank lid and the gas tank must be cleaned before refueling so as not to have debris entering the tank. The high branch saw should be placed in a flat place so that the fuel tank is facing up. Don't let the gasoline spill when you fill it up. Don't fill the tank too full. After refueling, always use your hands to tighten the fuel tank cover.You can only use high quality two stroke engine oil to ensure a longer engine life. Do not use an ordinary four stroke engine. When using other two stroke engine oils, the model shall be of grade TC quality. Poor quality gasoline or oil can damage the engine, seals, oil passages, and tanks.

- Q:How about the 06 saw in the broken aluminum door and window equipment? What are the characteristics? What is the difference between it and CNC saws?

- Broken bridge aluminum door and window equipment name LJZ2S-500 * 4200, broken bridge aluminum profile, double angle CNC cutting saw, LJZ2-450 * 3700 broken bridge aluminum door and window double angle cutting saw (06 saw)Motor Anhui Sanyang, power 2.2kw, Shanghai FENDA motor, power 1.5kwJapan and Japan saw blade diameter: 500mm thickness: 4.4mm WEMARO diameter: 450mm thickness: 4.0mmGuide to card too - 40mm linear bearing motion precision and stability of domestic circular guide - 50mmHead movement mode, CNC PLC control, high precision, ABBA screw drive motor drive, visual position, accuracy in general.Saw in and out of control square rail + slider (silver) control precision, travel 135mm long copper composite sleeve, driven by the cylinder, the trip up to 120mm

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Flat hacksaw Frame with Wooden Handle SJ-0130

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products