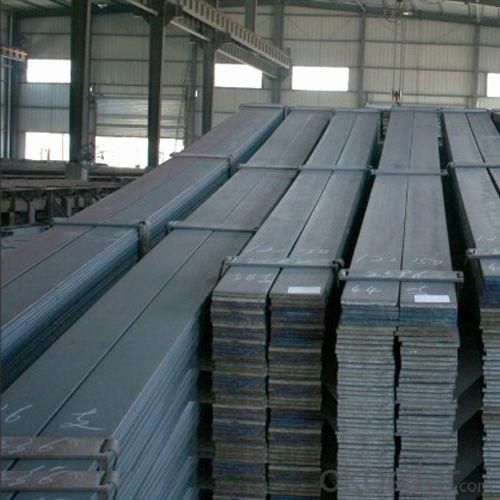

Flat Bar Sizes Slitting Manufacture Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Flat Bar For Many Sizes is used for manufacturing various types of springs and components, for the suspension mechanism in automobiles or the railways.With the short stress production line that can finish foundry and rolling in one process, we are able to produce dozens type of spring flat steel from 6*40mm to 20*150mm. This product is the best choice for springs and chains for car and agricultrure machine.

Product Description

Flat Bar Sizes Slitting Manufacture Steel Flat Bar

steel flat bar grade: A36, S235jr, St37-2, SS400, Q235, Q195

steel flat bar standard: ASTM, AISI, EN, DIN, JIS, GB

steel flat bar thickness:1.5mm-20mm

steel flat bar width: 10mm-1000mm

steel flat bar length: 6m, 9m, 12m or as your requirement.

steel flat bar technique: slitting hot rolled steel coil

Place of origin: Tianjin China (Mainland)

Products Advantages: 1. high quality

2. high dimensional accuracy

3. high utilization rate of material

4. saving cost price

General specification below:

Steel Flat Bar | |||

Width (mm) | Thickness (mm) | Length (m) | Theoretical Weight (kg/m) |

20 | 2.0 | 6/9/12 | 0.31 |

20 | 2.5 | 6/9/12 | 0.39 |

20 | 2.75 | 6/9/12 | 0.43 |

25 | 2.5 | 6/9/12 | 0.49 |

25 | 3.75 | 6/9/12 | 0.74 |

30 | 2.5 | 6/9/12 | 0.59 |

30 | 3.5 | 6/9/12 | 0.82 |

30 | 9.75 | 6/9/12 | 2.30 |

40 | 3.5 | 6/9/12 | 1.10 |

40 | 4.75 | 6/9/12 | 1.50 |

40 | 11.75 | 6/9/12 | 3.69 |

50 | 2.75 | 6/9/12 | 1.08 |

50 | 4.5 | 6/9/12 | 1.77 |

50 | 9.75 | 6/9/12 | 3.83 |

60 | 5.5 | 6/9/12 | 2.60 |

60 | 7.5 | 6/9/12 | 3.53 |

60 | 11.5 | 6/9/12 | 5.42 |

80 | 5.5 | 6/9/12 | 3.45 |

80 | 7.5 | 6/9/12 | 4.71 |

80 | 11.75 | 6/9/12 | 7.38 |

100 | 3.25 | 6/9/12 | 2.55 |

100 | 4.75 | 6/9/12 | 3.73 |

100 | 7.5 | 6/9/12 | 5.89 |

120 | 9.75 | 6/9/12 | 9.18 |

120 | 11.75 | 6/9/12 | 11.07 |

150 | 9.75 | 6/9/12 | 11.48 |

150 | 11.5 | 6/9/12 | 13.54 |

150 | 13.5 | 6/9/12 | 15.90 |

160 | 11.75 | 6/9/12 | 14.76 |

200 | 9.5 | 6/9/12 | 14.92 |

250 | 5.75 | 6/9/12 | 11.28 |

340 | 7.75 | 6/9/12 | 20.68 |

- Q: What are the different types of surface finishes for titanium steel flat bars?

- There are several different types of surface finishes available for titanium steel flat bars. Some of the most common ones include: 1. Mill finish: This is the most basic type of surface finish, where the flat bar is left as it is after being manufactured. It has a rough texture and may have visible marks from the manufacturing process. 2. Brushed finish: Also known as satin finish, this type of surface finish is achieved by brushing the flat bar with a fine abrasive material. It creates a smooth and consistent texture with fine parallel lines, giving it a refined and elegant look. 3. Polished finish: This surface finish involves polishing the flat bar with progressively finer abrasives until a smooth and reflective surface is achieved. It provides a shiny and mirror-like appearance, making it highly aesthetically pleasing. 4. Sandblasted finish: In this type of surface finish, the flat bar is blasted with fine sand or other abrasive particles at high velocity. It results in a textured and matte appearance, often with a slightly rough feel. 5. Anodized finish: Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the flat bar. This finish can be achieved in various colors and provides enhanced corrosion resistance and durability. 6. Powder-coated finish: Powder coating involves applying a dry powder to the surface of the flat bar, which is then cured under heat to form a durable and protective coating. It offers a wide range of colors and finishes, including matte, glossy, and textured options. These are just a few examples of the different types of surface finishes available for titanium steel flat bars. The choice of finish depends on the desired appearance, functionality, and specific requirements of the application.

- Q: Can steel flat bars be used for making shelving units?

- Yes, steel flat bars can definitely be used for making shelving units. Steel flat bars are strong and durable, making them an excellent choice for shelving units that need to support heavy items. They can be easily cut and welded to create the desired size and shape of the shelving unit. Steel flat bars also have a sleek and modern look, making them suitable for various styles of interiors. Additionally, steel is resistant to corrosion, which ensures that the shelving units will last for a long time without rusting or deteriorating. Overall, steel flat bars are a reliable and versatile material for constructing sturdy and functional shelving units.

- Q: Can steel flat bars be used in automotive applications?

- Yes, steel flat bars can be used in automotive applications. They are commonly used in various parts of automobiles such as brackets, frames, supports, and reinforcements due to their strength, durability, and ability to withstand high loads and impact.

- Q: Can steel flat bars be used for making brackets or supports for telecommunications equipment?

- Yes, steel flat bars can be used for making brackets or supports for telecommunications equipment. Steel is a strong and durable material that provides the necessary structural support for holding and securing telecommunications equipment in place. Its versatility and availability in various sizes make it suitable for constructing brackets and supports to meet the specific requirements of telecommunications installations.

- Q: Can steel flat bars be machined?

- Yes, steel flat bars can be machined. Machining involves the process of shaping, cutting, or drilling a material using machine tools. Steel is a versatile material that can be easily machined to meet specific requirements. Machining steel flat bars involves using various tools such as lathes, mills, drills, and grinders to cut, shape, or create holes in the metal. However, it is important to note that the machinability of steel can vary depending on its composition, hardness, and heat treatment. Proper tool selection, cutting speeds, and feeds are essential to achieve desired results while machining steel flat bars.

- Q: Can steel flat bars be used for making aerospace industry equipment or structures?

- When it comes to creating aerospace equipment or structures, steel flat bars are definitely a viable option. This is because steel is widely used in the aerospace industry due to its exceptional strength, durability, and ability to withstand extreme temperatures. In particular, flat bars are frequently utilized in aerospace applications because they are versatile and easy to work with. In the aerospace industry, steel flat bars are employed to manufacture a variety of components and structures, including frames, supports, brackets, and fittings. These bars can be easily cut, shaped, and welded to meet the specific design needs of aerospace equipment. Furthermore, they have excellent load-bearing capabilities, making them suitable for applications that require high strength and stability. However, it is crucial to keep in mind that the type of steel used for aerospace applications must meet rigorous quality and performance standards. The aerospace industry demands materials with exceptional mechanical properties, as well as resistance to corrosion and fatigue. Thus, steel flat bars used in this industry undergo extensive testing and certification processes to ensure that they are suitable for these demanding applications. To summarize, steel flat bars are a viable choice for creating aerospace equipment or structures. Their strength, versatility, and ease of fabrication make them valuable for various components in the aerospace industry, as long as they meet the necessary quality and performance standards.

- Q: Can steel flat bars be used for making stairs or handrails?

- Yes, steel flat bars can be used for making stairs or handrails. Steel is a durable and strong material, making it suitable for constructing stairs and handrails that can withstand heavy use and provide support. Steel flat bars can be shaped and welded to create the desired design and structure for stairs and handrails. Additionally, steel can be finished with various coatings or paints to enhance its aesthetic appeal and protect it from corrosion. Overall, steel flat bars are a popular choice for making stairs and handrails due to their strength, versatility, and durability.

- Q: What are the different types of surface finishes for copper steel flat bars?

- There are several different types of surface finishes that can be applied to copper steel flat bars. Some of the most common finishes include: 1. Mill finish: This is the standard finish that is applied to copper steel flat bars during the manufacturing process. It has a smooth and shiny appearance, but may have slight imperfections or marks from the milling process. 2. Polished finish: This finish involves buffing the surface of the flat bar to achieve a high shine and smooth texture. It is often used for decorative purposes or when a more refined look is desired. 3. Brushed finish: In this finish, the surface of the flat bar is brushed with a wire brush to create a textured appearance. It can be done in different directions to achieve different effects, such as horizontal or vertical brushing. 4. Satin finish: This finish has a smooth and matte appearance, with a subtle sheen. It is achieved by brushing the surface with a fine abrasive material, such as sandpaper or a nylon pad. 5. Antiqued finish: This finish is achieved by applying chemical treatments or patinas to the surface of the flat bar. It creates an aged or weathered appearance, adding character and depth to the metal. These are just a few examples of the different types of surface finishes that can be applied to copper steel flat bars. The choice of finish will depend on the desired aesthetic, functionality, and specific requirements of the project or application.

- Q: What are the common sizes of steel flat bars?

- The common sizes of steel flat bars vary depending on the specific application and the industry in which they are used. However, there are standard sizes that are commonly available in the market. Some common sizes of steel flat bars include: - 1/8" x 1/2" - 1/8" x 3/4" - 1/8" x 1" - 3/16" x 1/2" - 3/16" x 3/4" - 3/16" x 1" - 1/4" x 1/2" - 1/4" x 3/4" - 1/4" x 1" - 3/8" x 1/2" - 3/8" x 3/4" - 3/8" x 1" - 1/2" x 1/2" - 1/2" x 3/4" - 1/2" x 1" These sizes are commonly used in industries such as construction, manufacturing, and fabrication. It is important to note that these are just a few examples, and there may be other sizes available depending on specific requirements and customizations. It is always recommended to consult with a steel supplier or manufacturer to determine the most suitable size for your specific project.

- Q: How do steel flat bars compare to titanium flat bars?

- Both steel flat bars and titanium flat bars share some similarities, but they also have significant differences. When considering strength, titanium flat bars have a higher strength-to-weight ratio compared to steel flat bars. Titanium, a lightweight metal, possesses exceptional strength, making it perfect for applications that necessitate durability and lightness. On the other hand, steel is heavier but still sturdy, providing adequate strength for various purposes. In terms of corrosion resistance, titanium flat bars surpass steel flat bars. Titanium exhibits excellent corrosion resistance, even in harsh environments, rendering it highly suitable for applications in the marine, chemical, and aerospace industries. Conversely, steel is more susceptible to corrosion and requires protective coatings or regular maintenance to prevent rusting. Cost is another essential factor to consider. Generally, steel flat bars are more affordable than titanium flat bars. Titanium, being a relatively rare and expensive material, contributes to its higher price. On the contrary, steel is widely available and has a lower cost, making it a more cost-effective option for many applications. Moreover, titanium possesses unique properties that make it exceptional in certain industries. It showcases superb biocompatibility, making it valuable in medical and dental implants. Additionally, titanium is non-magnetic, making it useful in applications that require non-magnetic properties, such as aerospace and electronics. To summarize, titanium flat bars offer a higher strength-to-weight ratio, superior corrosion resistance, and distinctive properties like biocompatibility and non-magnetism. Steel flat bars, on the other hand, are more affordable while still providing satisfactory strength. Ultimately, the choice between the two will depend on the specific requirements of the application and the available budget.

Send your message to us

Flat Bar Sizes Slitting Manufacture Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords