Fireproof Calcium Silicate Board for Transfer Ladle

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fireproof Calcium Silicate Board for Transfer Ladle Details:

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: | |

| Type: | Non-Asbestos Fiber Cement B |

Packaging & Delivery

| Packaging Details: | wooden case in LCL, nake package in FCL |

| Delivery Detail: | 15 dyas after receipt of your deposit |

Product Description:

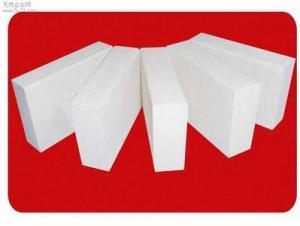

General information for Calcium silicate board:

CMAX calcium silicate products are classified under temperature between 650℃ to 1100℃, it’s an asbestos-free thermal insulation product.

Applications for Calcium silicate board:

◆Reheating furnace ◆Annealing furnace ◆Transfer ladle

◆Rotary kiln ◆Glass tank ◆Shuttle kiln

◆Tunnel kiln ◆Aluminum melting and holding furnace

Main Product Features:

◆Low thermal conductivity

◆High thermal insulation value

◆High strength

◆High strength

Product Specifications:

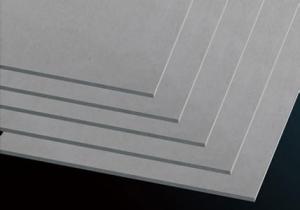

| base board Specification: | ||

| Size | Standard Size | Size:1220*2440*4/6/8/9/10/12/15mm |

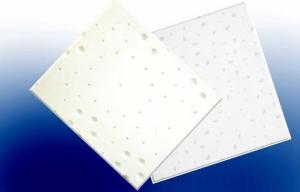

| Appearance | Surface | Surface:Un-Sanded/Sanded/Polished; |

| Edge | Square/Recessed/ | |

| Physical Properties | Density | 1.2-1.3g/cm3 |

| Bending Strength | Cross > 16Mpa | |

| Parallel 16-17Mpa | ||

| Moisture Movement | <0.20%< span=""> | |

| Water Absorption | < 0.1% | |

| Water Contain | <6%(Under EMS condition) | |

| Thermal Conductivity | 0.12-0.15 w/(m •k) | |

| Non-combustibility | GB 8624-2006 Grade A1,CE EN 12467:2012 Grade A1 | |

| Water Impermeablility | Traces of moisture appeared on the under surface of the sheet,but no formation of drops of water on the underside of the sheet after 24 hours. | |

| Freeze-thaw | Not have cracking and layering after freeze-thaw cycles 25 times. | |

| Application | Interior Ceiling,Interior Patition, Bottom Liner | |

| Products Warranty | More than 20 years | |

| Raw Material | Content |

| Cement | 44% |

| Quartz | 44% |

| Natural Fiber | 8% |

| Suspension | 4% |

| Composition of Finished Product | Content |

| Crystalloid of Calcium Silicate | 52% |

| Quartz | 30% |

| Calcium Carbonate | 10% |

| Cellulose | 8% |

FAQ

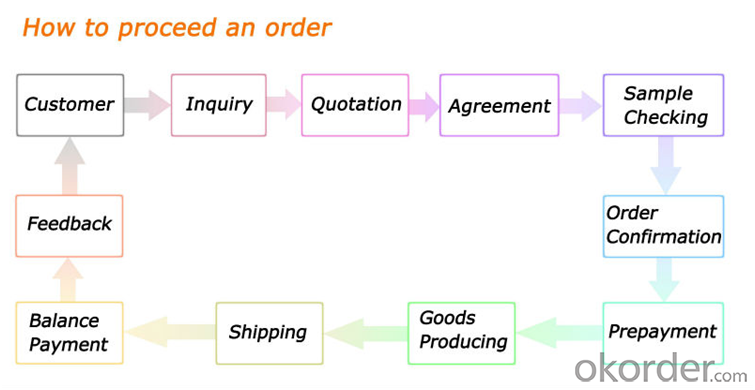

1. How to order ?

2.Can we accept OEM ?

YES! We can according your demand to produce.

3. Can we accept the detective of the third-party verification company ?

YES! We can accept the detective from any third-party verification company including the SGS, D&B and so on.

Our service:

üPrompt reply within 24 hours without delay by our specialized after-sale service sector.

üProvide high temperature solutions and professionals construction services for different fields for our customers.

üProvide the most reasonable logistics for customers to save every penny.

üProduction of goods are finished, thoughtful provide products and packaging photos for our customers.

- Q: My family in the north of the countryside, when the original building, the guest 粻 chicken class Tuen Jiu halo Mo hall with a high 1 meter wide and 50 cm tiles close to the wall around the circle, his wife said it looked good, do not want Yes, but the original is attached to the wall with cement, not easy to get down. I would like to ask, can not use gypsum board or plywood stick to the top, how to get, thank you! More

- Can be sealed with gypsum board on top, first in the tile surface drilling into the cork, the interval with 305m 粻 chicken class lesson wine tao Mo Mo * 305mm, and then 3 * 25 flat head tapping screw to the gypsum board fixed Tile surface, if you worry about wet, you can switch to 6% calcium silicate board (recommended use, but also cheaper 12% gypsum board). The simplest can be a single tiles chisel, keep the paste of the cement layer, and then leveling the cement slurry, you can paint the dust

- Q: What is the use of high-temperature calcium silicate board? I want to find a material can be resistant to high temperature 1500 ℃, and must be pressure,

- Calcium silicate does not meet this requirement

- Q: My house is the frame, the whole empty, use calcium silicate board wall, floor tile, is to do geotechnical, or carpentry?

- Of course, is the first wall! This kind of partition board tiles (geotechnical) can do! Carpentry can do! Done cut off, and then do touch the hundred bark know Du version of the forest security! And then do carpentry, carpentry is finished paving, shop brick is the oil workers!

- Q: Calcium silicate board model specifications

- Is a white, hard new insulation material, with a light weight, high strength, thermal conductivity of filial piety high temperature, corrosion resistance. Can cut, can saw and so on. Thickness according to design needs

- Q: Calcium silicate board can be recycled

- No recycling, crushing has no effect on the environment...

- Q: Silicon calcium board wall how to paste tiles

- 1, in the wall hanging steel wire mesh 2. Plastering will find a vertical wall to find the vertical 3. Do waterproof layer 4, on the wall side of the hair 5. Tiling

- Q: Living room to do silicon calcium board ceiling, whether need to put putty, brush latex paint?

- Recommended scraping putty, the purpose of many simple, enhanced, and other paint adhesion, hope satisfaction Thank you

- Q: Buy the house is fine decoration, wood flooring poor quality to tile bathroom ceiling is calcium silicate board, it is necessary to replace it? Need to change the material of the ceiling?

- If it is calcium carbonate plate can not be replaced, calcium silicate board itself tide!

- Q: Please specify the specific time and the problem, thank you, calcium silicate board is Han Debang, medium density, colorful paint is Pan Cai, imitation stone more

- Due to the density of calcium silicate board is relatively low absorption rate, although the water resistance is also good, even if the bubble in the water 1 month its physical properties are difficult to change, the oil horizon than the main words See is water-based acrylic or silicone C, but also divided into ordinary, shot, high bombs Manufacturers are generally committed to more than 6 years, silicon C can be more than 12 years.

- Q: One is better sound insulation, the second is the best not to knock the hotel that kind of boom pound sound. Is there a good recommendation? Thank you more

- I think two kinds of almost the key is the role of fiber from the absorption of sound. If you can not knock the sound, you try thick on the line.

Send your message to us

Fireproof Calcium Silicate Board for Transfer Ladle

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords