Painted Plywood Flooring - Finger Jointed Core Melamine Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Finger Jointed Core Melamine Faced Plywood are mostly used in decoration and furniture.

Characters:

Light, beautiful, easy to install and disassemble; less glue, more environmental.

Products Details:

Detailed Specification:

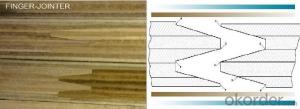

Product name: Finger Jointed Core Melamine Faced Plywood

Size:1220*2440 or as requested

Thickness: 12/15/18/21mm

Core: Finger Jointed Core (recycled plywood bars)

Glue: Mr/ E2

Face & Back: Melamine paper with different colors

Surface: satin, pearl, embossed wood grain and so on.

Density: 460-720KGS

Certificate: CE/ISO/FORM A&E

Usage: Furniture/Packing

Package:Inter packing: 0.20mm plastic bag

Outer packing: pallets are covered with thin plywood or carton and then 4*6 steel straps for strength.

Conveyance:

20’GP CNT-----8PLTS/22M3/15TONS

40’GP CNT----16PLTS/44M3/23TONS

40’HQ CNT----18PLTS/55M3/28TONS

Train: 48PLTS/110M3/60Tons/Train

Delivery time:

Within 15 days on receipt of deposit or original L/C

Min Order:1X40’FCL

Payment:L/C at sight, T/T(30%deposit)

Supply ability:5000 cubic meters/month

Main market: Middle east,Africa,UAE,Qatar,Oman,Russian,etc

FAQ:

Q1. What's the advantage of finger jointed core plywood compared with normal core plywood?

A1:It is more economical & environmental.

- Q: What is the general use of plywood in decoration works?

- Plywood is one of the common materials for furniture, one of the three panels of man-made board, but also for aircraft, ships, trains, cars, construction and packaging materials

- Q: Now what is the market for plywood development?

- the cumulative sales revenue was RMB 72,163,513,000, an increase of 39.25% over the same period in 2005; total accumulated profit 3,198,494,000 Yuan, compared with the same period in 2005 increased by 60.41%.

- Q: Class I resistant weather plywood Class II water resistant plywood

- Medium density fiberboard: density fiberboard is a kind of man-made sheet, it is the plant fiber as raw material, the chipping, fiber separation

- Q: What are the further processing of plywood?

- Direct printing plywood Direct print plywood is printed directly on the plywood surface with simulated wood grain or other patterns.

- Q: What is the best way to fix multi-layer plywood?

- The usual length and width specifications are: 1220 × 2440mm, while the thickness specifications are generally: 3,5,9,12,15,18 mm and so on

- Q: Plywood is a common material for furniture?

- Commonly used plywood type plywood, penta and so on. Plywood can improve timber utilization and is a major way to save wood

- Q: What is the type of plywood editing?

- the plywood is divided into decorative plywood (for the surface needs to paint transparent paint Furniture, sewing machines and all kinds of electrical appliances and other products)

- Q: What are the key points for plywood selection?

- may be damp the hidden parts and high demand for waterproof occasions should consider the use of Class I or II plywood, outdoor use of plywood should be used Ⅰ class plywood.

- Q: What is medium density fiberboard

- Plywood commonly known as three plywood, five plywood, nine PCT board, twelve PCT board and so on

- Q: Decorative veneer veneer plywood features

- Decorative veneer veneer plywood is made of natural wood decorative veneer affixed to the plywood made of wood-based panels.

Send your message to us

Painted Plywood Flooring - Finger Jointed Core Melamine Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords