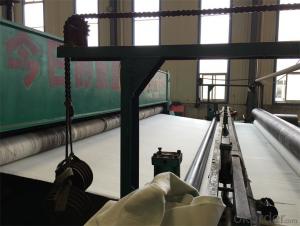

Fibra Geotextil Polypropylene Filter Non-Woven Geotextile for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

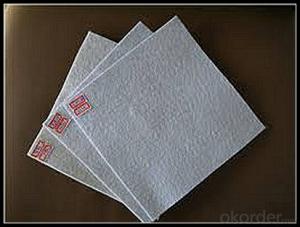

Specification

Product Features

Can self-seal small cracks while forming watertight laps at the seams.

Provides a strong mechanical bond to poured concrete.

Proven effective in structures under continuous or intermittent hydrostatic pressure-up to 70m (231 ft).

Can be installed in virtually any weather condition, including freezing temperatures and damp conditions. Can be installed on green concrete without primers or adhesives.

Proven effective in both vertical and horizontal applications-i.e., backfilled and property-line walls.

Filament Spunbond Nonwoven Geotextile Property:

Good creep property and hydraulics property,resistance to corrosion,

excellent anti-aging and heat-resistance quality.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the cost considerations for geotextile applications?

- Some cost considerations for geotextile applications include the initial purchase cost of the geotextile material, the cost of installation, and any additional costs associated with site preparation and maintenance. Other factors such as the size and complexity of the project, the type and quality of the geotextile material, and the expected longevity of the application also contribute to the overall cost. Additionally, the potential cost savings from using geotextiles, such as reduced construction time and improved long-term performance, should also be taken into account.

- Q: 300g / m2 geotextile package is what it means

- 300g / m2 Geotextile: refers to the weight of 300g per square meter (model) 300g / m2 geotextile package: refers to the outsourcing; with 300g of geotextile to wrap something; for example: With 300g / m2 geotextile wrapped gravel. The

- Q: How do geotextiles contribute to climate change adaptation?

- Geotextiles contribute to climate change adaptation by providing effective erosion control and soil stabilization measures. They help prevent soil erosion, which reduces the risk of landslides and other natural disasters caused by heavy rainfall and erosion. Geotextiles also improve water infiltration and drainage, leading to better water management in areas prone to flooding or droughts. Additionally, they promote vegetation growth, which aids in carbon sequestration and reduces greenhouse gas emissions. Overall, geotextiles play a crucial role in mitigating the impacts of climate change and enhancing the resilience of landscapes and infrastructure.

- Q: What are the different geotextile installation techniques for steep slopes?

- There are several geotextile installation techniques that can be used for steep slopes. These include anchoring the geotextile with soil nails or rock bolts, using geotextile wraps or sleeves around soil or rock slopes, and installing geotextile mats or grids on the slope surface. These techniques help to stabilize the slope, prevent erosion, and improve overall slope stability.

- Q: What are the factors to consider when selecting geotextiles for embankment stabilization?

- When selecting geotextiles for embankment stabilization, there are several important factors to consider. These include the strength and durability of the geotextile, its filtration and drainage properties, its compatibility with the soil and other materials, and its ability to withstand environmental conditions such as UV exposure and chemical exposure. Additionally, factors such as cost, installation requirements, and project-specific needs should also be taken into account.

- Q: What is the place of attention for the laying of geotextiles?

- (1) the use of the use of buried type: cover the thickness should not be less than 30cm (2) refurbishment system should be: cushion, impermeable layer, transition layer, protective layer composition. (3) soil to be solid, to avoid uneven subsidence, cracks, anti-seepage within the turf, root to clear. And the surface of the membrane with a small particle size of sand or clay as a protective layer. (4) laying the geomembrane do not pull too tight, both ends of the soil into the corrugated part of the soil is better, especially with the rigid material anchoring, should leave a certain amount of expansion and contraction. (5) construction, should avoid stones,

- Q: Can geotextiles be used in retaining wall drainage systems?

- Yes, geotextiles can be used in retaining wall drainage systems. Geotextiles are commonly used as a filter fabric to prevent the migration of fine particles into the drainage system, while allowing water to flow through. By placing geotextiles behind the retaining wall, they help to enhance the drainage efficiency and overall stability of the system.

- Q: 800g / m2 non-woven geotextile vertical permeability coefficient is generally how much

- 800g / m2 non-woven geotextile vertical permeability coefficient is: 6.1 × 10-2

- Q: Do you need to use geotextile for construction site? Mainly used where?

- Underground garage roof green

- Q: Are geotextiles resistant to fungal growth?

- Yes, geotextiles are generally resistant to fungal growth due to their synthetic nature and the materials they are made from.

Send your message to us

Fibra Geotextil Polypropylene Filter Non-Woven Geotextile for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords