Fiberglass Mat Tissue - Cheap E-Glass Roving Price Fiberglass Roving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Roving Price Cheap E-glass Roving Price

Introduction:

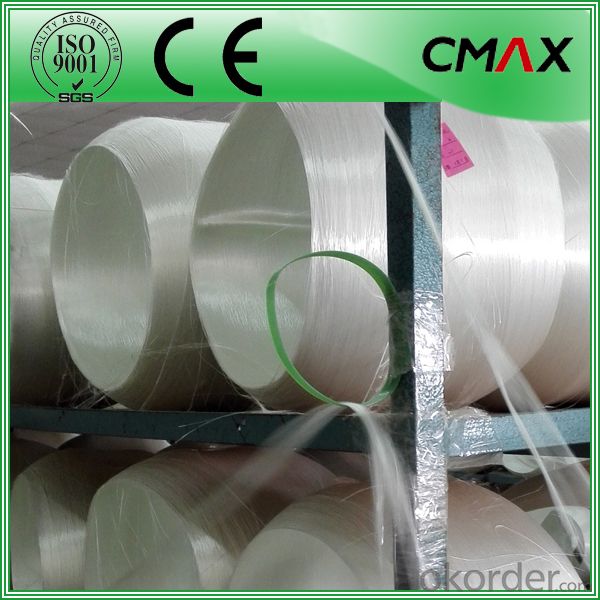

E-glass sprary-up roving, fiberglass gun roving, fiberglass roving is coated with a silance-based sizing, compatible with unsaturated polyester, vinyl ester and polyurethane resins.

It is a versatile general purpose spray-up roving used to manufacture boats, bathroom sinks ,yacht, sanitary ware, swimming pool and automotive parts and also pipe by centrifugal casting process.

Product Features:

1)Silane based coupling agent which delivers most balanced sizing properties.

2)Special sizing formulation which delivers good compatibility with martix resin.

3)Consistent fiber linear density,good mold ability and dispersion

4)Excellent mechanical properties of composite products

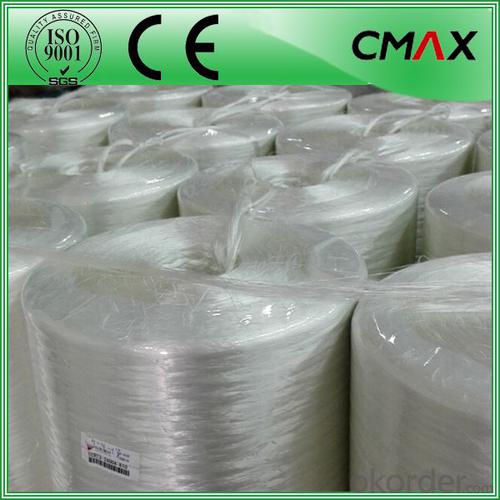

Packaging:

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Can fiberglass mat tissue be used for architectural sculptures?

- Certainly! Fiberglass mat tissue is an ideal choice for architectural sculptures. This versatile material finds extensive use across various applications, including the creation of architectural sculptures. Renowned for its lightweight nature, flexibility, and exceptional strength and durability properties, it proves itself as an excellent option for crafting intricate and detailed sculptures. The beauty of fiberglass mat tissue lies in its ability to be molded and shaped into various forms, enabling artists and sculptors to transform their creative visions into reality. Regardless of the sculpture's size or shape, this material allows for utmost creativity, whether it be a small decorative piece or a large-scale installation. Moreover, fiberglass mat tissue boasts resistance against adverse weather conditions and environmental elements, rendering it suitable for outdoor sculptures. Its capacity to withstand extreme temperature fluctuations, UV radiation, and moisture ensures the sculptures' integrity and aesthetic appeal remain unscathed for an extended period. To further enhance the desired aesthetic appearance, fiberglass mat tissue can be effortlessly painted and finished. The material readily accepts various paints, varnishes, or finishes, providing artists with the means to elevate the visual appeal and safeguard the sculpture's surface against potential damage. All in all, fiberglass mat tissue serves as a reliable and versatile medium for artists and sculptors alike to create architectural sculptures. Its robustness, durability, and adaptability make it an exceptional choice for translating artistic visions into tangible masterpieces within the realm of architecture.

- Q: How does fiberglass mat tissue perform in terms of UV resistance?

- Fiberglass mat tissue generally has good UV resistance. UV resistance refers to the ability of a material to withstand the harmful effects of ultraviolet radiation from the sun without degrading or deteriorating. Fiberglass mat tissue is usually manufactured using a combination of fiberglass and a binder material, which provides strength and integrity to the tissue. The fiberglass component in the mat tissue provides inherent UV resistance. Fiberglass is known for its durability and ability to resist degradation from UV exposure. It is a non-porous material that does not absorb UV radiation, making it less susceptible to damage caused by the sun's rays. Additionally, some manufacturers may apply a UV-resistant coating or treatment to the fiberglass mat tissue to enhance its UV resistance. This coating or treatment can further protect the tissue from the damaging effects of prolonged exposure to UV radiation. Overall, fiberglass mat tissue performs well in terms of UV resistance. It is a durable material that can withstand the harmful effects of UV radiation, making it suitable for applications where prolonged exposure to sunlight is expected. However, it is important to note that the specific UV resistance of fiberglass mat tissue may vary depending on the manufacturing process, quality of materials used, and any additional coatings or treatments applied.

- Q: What is the thickness range of fiberglass mat tissue?

- The thickness of fiberglass mat tissue may vary depending on the product and manufacturer at hand. Generally, one can find fiberglass mat tissues in thicknesses that span from 0.1mm to 1mm. It is worth emphasizing that the thickness of the fiberglass mat tissue plays a significant role in determining its strength, flexibility, and various other qualities. Therefore, it is imperative to carefully choose the suitable thickness that aligns with the intended application.

- Q: How does fiberglass mat tissue perform in terms of moisture absorption?

- Fiberglass mat tissue boasts exceptional moisture absorption capabilities. Its composition of fine fibers grants it a large surface area, allowing for swift moisture absorption. Moreover, fiberglass mat tissue exhibits hydrophobic properties, repelling water and preventing prolonged moisture retention. This attribute renders it an optimal material for moisture-resistant applications, including the construction of waterproofing membranes or the production of boats and water tanks. In sum, fiberglass mat tissue showcases remarkable performance in averting moisture absorption and upholding its structural integrity, even within damp surroundings.

- Q: Are there any environmental considerations when using fiberglass mat tissue?

- There are numerous factors to consider in terms of the environment when utilizing fiberglass mat tissue. First and foremost, the production process for fiberglass mat tissue necessitates the consumption of energy and resources. This involves extracting non-renewable raw materials like silica sand, limestone, and soda ash. Furthermore, the energy-intensive procedure of melting these materials at high temperatures contributes to greenhouse gas emissions. In addition, the manufacturing of fiberglass entails the utilization of chemicals such as resins and binders, which can be environmentally harmful if not properly managed. If these chemicals are not handled and disposed of correctly, there is a potential risk of them seeping into water bodies or soil. Moreover, fiberglass mat tissue is not capable of biodegradation. It can take hundreds of years for it to decompose in a landfill. Inadequate disposal of fiberglass mat tissue can lead to environmental pollution and contribute to the ongoing waste management issue. Lastly, the use of fiberglass mat tissue in certain applications, such as insulation or construction, can have implications on energy efficiency. While fiberglass is an effective insulator, its production and installation may require additional energy inputs, such as the use of fossil fuels for transportation or heating during installation. To address these environmental considerations, it is crucial to promote sustainable practices in the production and use of fiberglass mat tissue. This can involve implementing energy-efficient manufacturing processes, reducing the utilization of harmful chemicals, encouraging the recycling or reuse of fiberglass materials, and exploring alternative materials with lower environmental impacts.

- Q: What is the expected lifespan of fiberglass mat tissue in residential applications?

- The expected lifespan of fiberglass mat tissue in residential applications can vary depending on various factors such as the quality of the material, the installation process, and the environmental conditions it is exposed to. However, on average, fiberglass mat tissues are designed to have a lifespan of around 20 to 30 years. Fiberglass mat tissues are commonly used in residential applications for reinforcing and strengthening purposes, particularly in areas prone to moisture and water damage such as bathrooms, kitchens, and basements. They are known for their excellent resistance to mold, mildew, and rot, making them a popular choice in these areas. With proper installation and maintenance, fiberglass mat tissues can provide long-lasting support and protection to the underlying surfaces. However, it is important to note that they can be susceptible to damage if not handled or installed correctly. Any improper installation or exposure to extreme conditions such as excessive heat or direct sunlight can significantly reduce their lifespan. Regular inspection and maintenance of fiberglass mat tissues are essential to ensure their optimal performance and longevity. This may include checking for any signs of wear, tear, or water damage, and promptly addressing any issues that arise. Additionally, periodic cleaning and sealing can help prolong the lifespan of the material. In summary, while the expected lifespan of fiberglass mat tissue in residential applications is typically around 20 to 30 years, it is crucial to consider factors such as quality, installation, and maintenance to ensure its durability and longevity.

- Q: How does fiberglass mat tissue perform in terms of moisture resistance?

- Fiberglass mat tissue performs excellently in terms of moisture resistance. Its dense structure and composition make it highly resistant to water absorption, preventing moisture from seeping through and causing damage to the underlying material. This property makes fiberglass mat tissue an ideal choice for various applications where moisture protection is crucial, such as in the construction of roofs, walls, and insulation.

- Q: How does the surface finish of fiberglass mat tissue affect its adhesion to resin?

- The adhesion of resin to fiberglass mat tissue can be significantly influenced by its surface finish. The surface finish pertains to the texture or smoothness of the fiberglass mat tissue. In general, a rough surface finish tends to promote better adhesion to resin. This is because a rough surface provides a larger area for the resin to adhere to, resulting in a stronger bond. Rough surface finishes can be achieved through different manufacturing techniques, such as using coarser fibers or incorporating texturizing agents during production. On the contrary, a smoother surface finish may lead to weaker adhesion. A smooth surface does not offer as much area for the resin to bond with, resulting in a weaker and less durable bond. Smoother surface finishes can be attained by using finer fibers or through additional processing steps to smoothen the surface. When selecting the surface finish of fiberglass mat tissue, it is crucial to consider the specific application and requirements. For applications that necessitate high strength and durability, a rougher surface finish may be preferable to ensure optimal adhesion to the resin. Conversely, for applications where a weaker bond is acceptable or where a smoother surface finish is desired for aesthetic reasons, a smoother surface finish may be chosen. Ultimately, the surface finish of fiberglass mat tissue plays a vital role in determining the adhesion to resin. It is essential to choose the appropriate surface finish to achieve the desired strength, durability, and performance in various applications.

- Q: Can fiberglass mat tissue be used for reinforcing concrete structures?

- Yes, fiberglass mat tissue can be used for reinforcing concrete structures. It provides additional strength and durability to the concrete, enhancing its resistance to cracking and improving its overall structural integrity.

- Q: What are the potential health and safety concerns associated with working with fiberglass mat tissue?

- Working with fiberglass mat tissue can pose potential health and safety concerns. The fine fiberglass particles present in the air during handling and cutting can be inhaled, leading to respiratory issues such as irritation, coughing, and difficulty breathing. Prolonged exposure to these particles may also result in long-term lung damage. Additionally, direct skin contact with the fiberglass can cause skin irritation and allergic reactions. Hence, it is important to use appropriate personal protective equipment, such as gloves, masks, and goggles, to minimize these risks and ensure a safe working environment.

Send your message to us

Fiberglass Mat Tissue - Cheap E-Glass Roving Price Fiberglass Roving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords