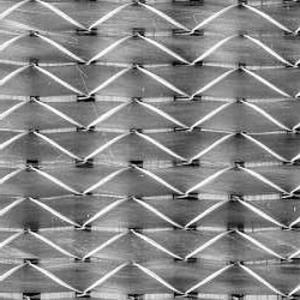

Fiberglass Mat Tissue - Multiaxial Fabric-UD, 950gsm, 0°:750g Chopping:200g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

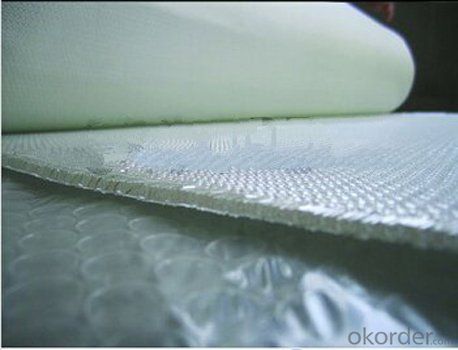

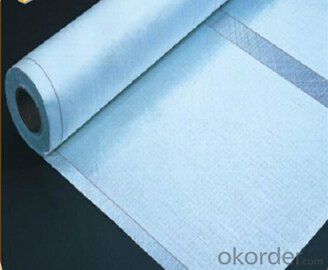

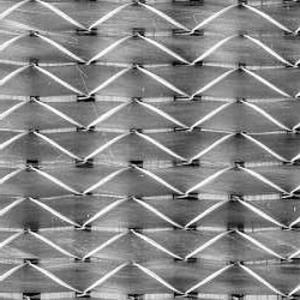

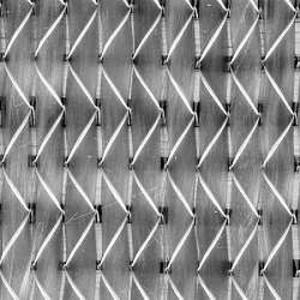

◎ This fabric is made of fiberglass roving which are aligned at 0° or 90° into one layer of roving by stitching together with or without one layer of chopped strand. It is mainly applied in the hand lay up, RTM and other close molding processes.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mainly be used as reinforced materials in the composite material industry: engine room casing, wind deflector, boat, auto frame and pultrusion profiles,etc.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ Small gap between fibers, Increased strength, reduced product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

A:Are you a manufacturer or trading company?

Q:Low price can be offered to you because we are not only a trade company but a manufacturer.We have our factory.

A: How Long have you been in this line for fiberglass?

Q: 10 years working experiences specializing in the production and sale of Fiberglass and other related products.

- Q: Can fiberglass mat tissue be used for soundproofing?

- Indeed, soundproofing can be achieved with the utilization of fiberglass mat tissue. Renowned for its remarkable sound absorption capabilities, fiberglass proves to be an exceptional choice. Whether employed as a mat or tissue, it effectively diminishes noise transmission by absorbing and attenuating sound waves. The porous composition of fiberglass enables it to capture and disperse sound energy, rendering it a perfect material for soundproofing purposes. Furthermore, fiberglass possesses the advantages of being lightweight, flexible, and straightforward to install, thus making it an exceedingly convenient option for soundproofing endeavors.

- Q: Is fiberglass mat tissue suitable for insulation in wastewater treatment plants?

- Yes, fiberglass mat tissue is suitable for insulation in wastewater treatment plants. It is a commonly used material for insulation due to its excellent thermal resistance, resistance to moisture and chemicals, and its ability to withstand high temperatures. Additionally, fiberglass mat tissue is lightweight and easy to install, making it an efficient choice for insulation in wastewater treatment plants.

- Q: Is fiberglass mat tissue suitable for wastewater treatment applications?

- Yes, fiberglass mat tissue is suitable for wastewater treatment applications. Fiberglass mat tissue is a material that is resistant to chemicals, corrosion, and degradation, making it an ideal choice for various industrial applications, including wastewater treatment. It can be used as a filtration media to separate solid particles from wastewater, as a lining material to prevent corrosion in tanks and pipes, and as a reinforcement material for concrete structures used in wastewater treatment plants. Additionally, fiberglass mat tissue has excellent mechanical strength, dimensional stability, and thermal resistance, which further enhance its suitability for wastewater treatment applications. Overall, fiberglass mat tissue is a reliable and effective material for use in wastewater treatment processes.

- Q: How does fiberglass mat tissue perform in terms of moisture absorption?

- Fiberglass mat tissue boasts exceptional moisture absorption capabilities. Its composition of fine fibers grants it a large surface area, allowing for swift moisture absorption. Moreover, fiberglass mat tissue exhibits hydrophobic properties, repelling water and preventing prolonged moisture retention. This attribute renders it an optimal material for moisture-resistant applications, including the construction of waterproofing membranes or the production of boats and water tanks. In sum, fiberglass mat tissue showcases remarkable performance in averting moisture absorption and upholding its structural integrity, even within damp surroundings.

- Q: How does the roll weight of fiberglass mat tissue affect its transportation?

- The roll weight of fiberglass mat tissue directly affects its transportation in terms of the ease and cost. Heavier rolls will require more effort and resources for handling, loading, and unloading. They may also require specialized equipment for transportation, leading to higher shipping costs. On the other hand, lighter rolls are easier to handle and transport, reducing the overall logistical challenges and expenses.

- Q: Does fiberglass mat tissue provide any UV resistance?

- Yes, fiberglass mat tissue does provide some level of UV resistance. The resin used to bind the fibers in the fiberglass mat tissue helps protect it from the harmful effects of UV radiation. However, prolonged exposure to sunlight can still cause some degradation over time, so additional UV protection measures may be necessary for long-term durability.

- Q: Can fiberglass mat tissue be used for making furniture?

- No, fiberglass mat tissue is not suitable for making furniture. It is primarily used in composite materials and construction applications, not for furniture manufacturing.

- Q: Is fiberglass mat tissue resistant to mold and mildew?

- Yes, fiberglass mat tissue is resistant to mold and mildew due to its non-porous and moisture-resistant properties.

- Q: What are the properties of fiberglass mat tissue?

- Fiberglass mat tissue, also referred to as fiberglass mat or fiberglass matting, is a non-woven material made from glass fibers, possessing numerous properties that render it suitable for diverse applications. 1. With regards to strength and durability, fiberglass mat tissue is renowned for its high tensile strength, enabling it to endure substantial stress without fracturing. This quality makes it ideal for fortifying and reinforcing various materials and structures. 2. Despite its strength, fiberglass mat tissue remains relatively lightweight, facilitating easy handling and transportation. This characteristic proves particularly advantageous in industries where weight reduction plays a crucial role, such as aerospace and automotive. 3. The flexibility of fiberglass mat tissue allows it to conform to curved surfaces and intricate shapes. Consequently, it proves versatile and appropriate for applications requiring the material to be molded or shaped into specific designs. 4. Fiberglass mat tissue exhibits excellent resistance to various chemicals, including acids, alkalis, and most solvents. This attribute renders it suitable for use in corrosive environments, such as chemical processing plants or storage tanks. 5. Fiberglass mat tissue possesses commendable thermal insulation properties, effectively reducing heat transfer. Consequently, it proves valuable in applications necessitating heat insulation, such as the construction of walls, roofs, or insulation boards. 6. Inherently fire-resistant, fiberglass mat tissue does not contribute to the propagation of flames. As a result, it finds extensive use in applications where fire safety is paramount, such as the production of fire-resistant doors, panels, or insulation materials. 7. Furthermore, fiberglass mat tissue offers excellent sound insulation properties, diminishing the transmission of noise through walls or other structures. This characteristic renders it suitable for implementation in soundproofing applications, such as recording studios or automotive interior panels. Overall, the properties exhibited by fiberglass mat tissue endow it with versatility, allowing for a wide range of applications across various industries, including construction, automotive, aerospace, and marine. Its strength, flexibility, lightweight nature, chemical resistance, thermal and sound insulation properties, as well as its fire resistance, contribute to its popularity and usefulness in numerous applications.

- Q: Is fiberglass mat tissue compatible with different types of resins?

- Yes, fiberglass mat tissue is compatible with different types of resins. It is commonly used in the construction industry as a reinforcement material for various resin systems, including polyester, epoxy, and vinyl ester resins. The compatibility of fiberglass mat tissue with different resins makes it versatile and suitable for a wide range of applications.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD, 950gsm, 0°:750g Chopping:200g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords