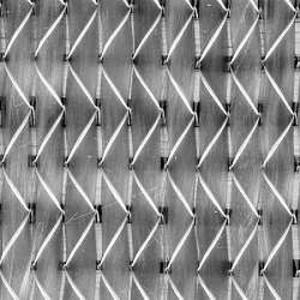

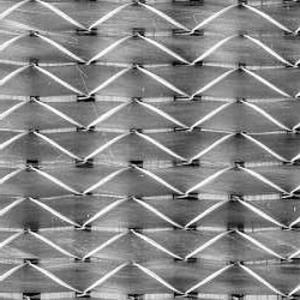

Fiberglass Mat Tissue - Multiaxial Fabric-UD (0°:700g, 90°:50g, Chopping:200g)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ This fabric is made of fiberglass roving which are aligned at 0° or 90° into one layer of roving by stitching together with or without one layer of chopped strand. It is mainly applied in the hand lay up, RTM and other close molding processes.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ Small gap between fibers, Increased strength, reduced product weight and better surface finish. ◎ Mechanical property of different directions is adjustable. ◎The multi-layers structure could simplify forming process, improve operation efficiency. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. Can you provide sample?

Yes, we can offer free sample for you.

- Q: Can fiberglass mat tissue be used for repairing fiberglass structures?

- Yes, fiberglass mat tissue can be used for repairing fiberglass structures. Fiberglass mat tissue is a versatile material that is commonly used in the construction and repair of fiberglass structures. It is designed to provide strength, stability, and reinforcement to the damaged areas of the structure. The mat tissue is typically applied with resin, which helps to bond the fibers together and create a durable repair. It is especially effective for repairing cracks, holes, and other types of damage in fiberglass surfaces. Overall, fiberglass mat tissue is an excellent choice for repairing fiberglass structures due to its strength, flexibility, and ability to conform to various shapes and sizes.

- Q: Does fiberglass mat tissue absorb water?

- Yes, fiberglass mat tissue does absorb water.

- Q: Does fiberglass mat tissue require any special curing conditions?

- Yes, fiberglass mat tissue does require special curing conditions. It typically needs to be cured at specific temperature and humidity levels for a specific duration of time in order to achieve optimal strength and performance.

- Q: How is fiberglass mat tissue used in the production of composite panels?

- Due to its unique properties and versatility, fiberglass mat tissue is commonly utilized in the manufacturing of composite panels. Its role as a reinforcement material contributes to the enhancement of strength, durability, and overall performance of these panels. In the production process, a sandwich structure is typically formed by incorporating fiberglass mat tissue between layers of resin. This tissue serves as a reinforcing layer, providing added strength and stability to the panels. It effectively distributes applied stress evenly across the panel, thereby reducing the likelihood of cracks or fractures. One notable advantage of fiberglass mat tissue is its ability to enhance the impact resistance of composite panels. By absorbing and dispersing energy when subjected to external forces, it diminishes the risk of damage or breakage. This characteristic makes it a highly suitable choice for applications that necessitate high impact resistance, such as automotive parts, boat hulls, or aircraft components. Furthermore, fiberglass mat tissue exhibits excellent resistance to corrosion, making it appropriate for usage in environments with high humidity or exposure to chemicals. It acts as a protective barrier, shielding the composite panels from moisture and corrosive substances. As a result, the panels enjoy an extended lifespan and sustained performance. Moreover, fiberglass mat tissue possesses exceptional moldability, which facilitates the creation of intricate shapes and designs. It can be effortlessly molded into various forms, thus offering flexibility in the production process and enabling the fabrication of customized composite panels tailored for specific applications. In summary, fiberglass mat tissue is a vital component in the manufacturing of composite panels. It reinforces the structure, enhances impact resistance, improves corrosion resistance, and enables design flexibility. Its unique properties have made it a favored choice in industries such as construction, transportation, aerospace, and marine, where the demand for high-performance and long-lasting composite panels is prevalent.

- Q: What are the different thickness tolerances for fiberglass mat tissue?

- The thickness tolerances for fiberglass mat tissue can differ depending on the manufacturer and product specifications. Generally, fiberglass mat tissue is offered in a range of thickness tolerances from 0.5 millimeters (mm) to 3 mm. The tolerance represents the acceptable range of thickness variation within a product. For instance, a fiberglass mat tissue with a thickness tolerance of +/- 0.5 mm means that the actual thickness can deviate by up to 0.5 mm in either direction from the specified thickness. The required tolerance for a specific application depends on the intended use and desired precision. Thicker fiberglass mat tissues with smaller tolerances are commonly utilized in applications that demand greater strength and durability, like reinforcing concrete in the construction industry or manufacturing composite materials. Conversely, thinner fiberglass mat tissues with larger tolerances may be employed in applications where flexibility and conformability take precedence, such as insulation or soundproofing in the automotive industry. To obtain accurate information regarding available thickness tolerances for fiberglass mat tissue, it is crucial to refer to the manufacturer's specifications or contact a supplier. These tolerances can significantly vary based on the specific product and supplier.

- Q: How is fiberglass mat tissue used in the production of water tanks?

- Fiberglass mat tissue is used in the production of water tanks to provide reinforcement and durability. It is applied as a layer between the inner and outer walls of the tank to enhance its structural integrity and prevent leakage. The fiberglass mat tissue acts as a barrier against corrosion, increases the tank's resistance to external factors such as temperature changes and chemicals, and improves its overall strength.

- Q: How does fiberglass mat tissue compare to other types of reinforcement materials?

- Fiberglass mat tissue is a versatile reinforcement material that offers several advantages over other types of reinforcement materials. Firstly, it has excellent strength and stiffness properties, providing superior load-bearing capabilities compared to other materials. Secondly, fiberglass mat tissue is lightweight, making it easier to handle and install. Additionally, it is highly resistant to corrosion, chemicals, and moisture, ensuring long-term durability. Lastly, fiberglass mat tissue has excellent dimensional stability and is not prone to warping or shrinking, making it a reliable choice for various applications. Overall, its combination of strength, lightweight nature, durability, and dimensional stability sets fiberglass mat tissue apart from other reinforcement materials.

- Q: How does the fiber orientation of fiberglass mat tissue affect its strength?

- The fiber orientation of fiberglass mat tissue plays a significant role in determining its strength. Fiberglass mat tissue is a composite material made up of randomly distributed glass fibers held together by a binder material. The strength of this material is highly influenced by the orientation of these fibers. When the fibers in fiberglass mat tissue are randomly oriented, it results in a material with isotropic strength properties. This means that the material exhibits similar mechanical properties, such as tensile strength and stiffness, in all directions. Random fiber orientation provides a balanced distribution of load-bearing capability throughout the material, making it resistant to both tensile and compressive forces from any direction. On the other hand, if the fibers in fiberglass mat tissue are oriented in a specific direction, it creates an anisotropic material with directional strength properties. In this case, the material becomes stronger and stiffer along the direction of the fibers, while its strength decreases in other directions perpendicular to the fiber orientation. This anisotropic behavior is due to the fact that the fibers primarily carry the load, while the binder material acts as a support and provides cohesion between the fibers. By manipulating the fiber orientation during the manufacturing process, it is possible to tailor the strength and performance characteristics of fiberglass mat tissue to specific applications. For example, in applications where strength is required in a particular direction, such as in the construction industry for reinforcing concrete or in the aerospace industry for structural components, the fibers can be aligned to provide maximum strength along the desired load path. In summary, the fiber orientation of fiberglass mat tissue directly affects its strength. Random fiber orientation results in isotropic strength properties, providing balanced strength in all directions. Conversely, specific fiber alignment creates anisotropic strength properties, enabling enhanced strength along the direction of the fibers. This ability to control the fiber orientation allows for the customization of fiberglass mat tissue to meet the specific strength requirements of various industries and applications.

- Q: Can fiberglass mat tissue be used for insulation in cleanrooms?

- Fiberglass mat tissue can indeed be used for insulation in cleanrooms. It offers several advantages that make it a suitable choice for such applications. Firstly, fiberglass mat tissue has excellent thermal insulation properties, which helps to maintain the desired temperature and prevent heat transfer in cleanrooms. This is crucial in environments where temperature control is essential for processes or equipment. Additionally, fiberglass mat tissue has good acoustic insulation capabilities, which can help in reducing noise levels within cleanrooms. This is particularly important in cleanrooms where sensitive equipment or experiments are conducted, as minimizing noise disturbances can ensure accurate and reliable results. Furthermore, fiberglass mat tissue is non-combustible, meaning it does not catch fire easily. This adds an extra layer of safety in cleanrooms where flammable materials or volatile substances may be present. The non-combustible nature of fiberglass mat tissue also contributes to its overall durability and longevity. Lastly, fiberglass mat tissue is resistant to moisture, making it suitable for cleanrooms where humidity control is crucial. It does not absorb moisture, preventing the growth of mold or mildew, which can be detrimental to cleanroom environments. Overall, fiberglass mat tissue is a viable option for insulation in cleanrooms due to its thermal and acoustic insulation properties, non-combustible nature, and resistance to moisture. Its use can contribute to maintaining the desired conditions within cleanrooms and ensuring the integrity of processes and equipment.

- Q: Can fiberglass mat tissue be used for repairing fiberglass canoes?

- Yes, fiberglass mat tissue can be used for repairing fiberglass canoes. It is commonly used to reinforce and strengthen the damaged areas of the canoe by providing additional structural support.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD (0°:700g, 90°:50g, Chopping:200g)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords