Fiberglass Mat Tissue C-Glass Woven Roving for Pultrusion

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

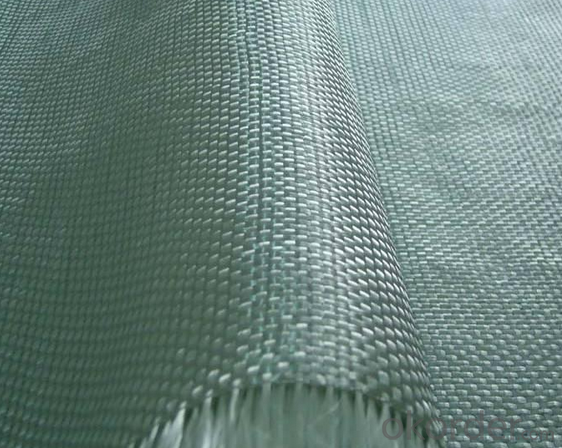

Structure of Woven Roving

1)Low Fuzz

2)Fast Wet-out&Impregnation

3)Easy Lay-up&Air Release

4)Excellent Mechanical Strength

5)Good Wet Strength Retension

6)Good Laminate Transparency

Main Features of Woven Roving

1.CWR400

2.360-380g/m2

3.77.5px or 2250px width

4.plastic woven bag

Application of Woven Roving

Unit | Product No. | Weight(gsm) | Technique | Moisture content | combustible matter content(%) |

M | EWR260 | 264±13 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR270 | 261±13.5 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR360 | 354±18 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR500 | 504±25 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR580 | 576±29 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR600 | 622±30 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR800 | 850±40 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR200 | 200±15 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR400 | 385±30 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR600 | 600±45 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR800 | 810±40 | Plain | ≤0.15 | 0.40-0.80 |

Images:

FAQ of Woven Roving

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: Is fiberglass mat tissue chemically resistant?

- Yes, fiberglass mat tissue is chemically resistant.

- Q: What are the different reinforcement orientations available for fiberglass mat tissue?

- Fiberglass mat tissue offers several reinforcement orientations, each intended for specific purposes in different applications. One common orientation is unidirectional reinforcement, where fibers align in one direction. This orientation provides great strength and stiffness in that alignment, making it suitable for applications requiring resistance to tension or bending forces in a single direction. Another orientation is bidirectional reinforcement, where fibers align in two perpendicular directions. This orientation provides equal strength and stiffness in both directions, making it ideal for applications needing resistance to tension and compression forces. Structural components like panels, pipes, and tanks commonly employ bidirectional reinforcement. A third orientation is randomly oriented reinforcement, where fibers distribute randomly. This orientation offers isotropic properties, meaning it provides similar strength and stiffness in all directions. Random reinforcement is often used in applications requiring uniform strength and flexibility, like automotive parts, boat hulls, and sporting goods. Furthermore, hybrid reinforcement orientations are available, combining different fibers or orientations to meet specific performance requirements. These hybrids offer a combination of strength, stiffness, flexibility, and other desired properties, making them suitable for a wide range of applications. Overall, the choice of reinforcement orientation for fiberglass mat tissue depends on the application's specific requirements, including desired mechanical properties, forces to be resisted, and other performance considerations.

- Q: Is fiberglass mat tissue suitable for insulation in hospitals?

- Yes, fiberglass mat tissue is suitable for insulation in hospitals. Fiberglass mat tissue is a lightweight and cost-effective material that offers excellent thermal insulation properties. It can effectively regulate temperature and reduce heat loss, making it an ideal choice for hospitals where maintaining a comfortable and controlled environment is crucial. Additionally, fiberglass mat tissue is non-combustible and resistant to mold, ensuring a safe and hygienic environment in hospitals. Its durability and ease of installation also make it a practical choice for insulation in healthcare facilities.

- Q: Is fiberglass mat tissue compatible with different resin systems?

- Fiberglass mat tissue is indeed compatible with different resin systems. This versatile material can be utilized with a variety of resin systems, such as polyester, epoxy, and vinyl ester resins. Its exceptional wet-out properties enable the resin to be absorbed and distributed evenly throughout the mat. Consequently, this compatibility facilitates the fabrication of robust and long-lasting composite structures for numerous industries, including automotive, marine, construction, and aerospace. Nevertheless, it is crucial to carefully assess the unique properties and characteristics of the resin system employed to guarantee optimal performance and compatibility with the fiberglass mat tissue.

- Q: How does the strength of fiberglass mat tissue compare to other reinforcement materials?

- The strength of fiberglass mat tissue is comparable, if not superior, to other reinforcement materials. It offers excellent tensile strength, high resistance to corrosion, and good thermal insulation properties. Additionally, it is lightweight, flexible, and cost-effective, making it a popular choice in various industries such as construction, automotive, and aerospace.

- Q: Can fiberglass mat tissue be used for making surfboards?

- Surfboards can indeed be made using fiberglass mat tissue. This material, known for its lightweight yet robust properties, is commonly utilized in constructing surfboards. Typically, it is combined with epoxy resin to form a sturdy and durable surface. By incorporating fiberglass mat tissue, surfboards gain the strength and flexibility necessary to endure the demanding conditions encountered while riding waves. Moreover, the smooth and sleek texture of the material enhances the surfboard's performance and speed. In summary, fiberglass mat tissue is a favored option for constructing high-performance surfboards due to its exceptional strength-to-weight ratio.

- Q: What is the delamination strength of fiberglass mat tissue?

- The delamination strength of fiberglass mat tissue refers to its ability to resist the separation or detachment of layers within the material. This strength is dependent on various factors such as the quality of the resin used, the thickness and density of the mat, and the manufacturing process. Fiberglass mat tissue is typically designed to have a high delamination strength to ensure its durability and structural integrity. The mat is composed of multiple layers of glass fibers held together by a binder or resin. The bonding between these layers is crucial in preventing delamination. The delamination strength of fiberglass mat tissue can be determined through various testing methods, such as the peel test, where the force required to separate the layers is measured. This test provides valuable information about the adhesive strength between the layers and helps in assessing the overall quality of the material. The delamination strength can vary depending on the specific application and requirements. For example, fiberglass mat tissue used in construction or automotive industries may have different delamination strength specifications compared to those used in marine or aerospace applications. Manufacturers typically provide technical data or specifications indicating the delamination strength of their fiberglass mat tissue products. It is important to note that the delamination strength of fiberglass mat tissue can be influenced by external factors such as exposure to extreme temperatures, moisture, or chemical substances. Therefore, proper installation, maintenance, and adherence to recommended usage guidelines are essential to maintaining the desired delamination strength and overall performance of the material.

- Q: How does fiberglass mat tissue perform in terms of dimensional stability?

- The dimensional stability of fiberglass mat tissue is exceptional. This is due to its unique composition and manufacturing process, which result in minimal shrinkage or expansion when exposed to temperature variations or moisture. As a result, fiberglass mat tissue is an ideal material for various applications in the construction industry, where dimensional stability is crucial. It is commonly used to reinforce walls, roofs, and floors. The consistent size and shape of fiberglass mat tissue ensure that it maintains its original dimensions over time, providing long-lasting durability and reliability. Furthermore, its dimensional stability allows for precise cutting, shaping, and installation, reducing waste and increasing efficiency in manufacturing processes. Overall, the excellent dimensional stability of fiberglass mat tissue makes it a preferred choice in industries where accurate and stable dimensions are essential.

- Q: Does fiberglass mat tissue require any surface preparation before application?

- Yes, fiberglass mat tissue typically requires some surface preparation before application. This is to ensure proper adhesion and bonding between the fiberglass mat tissue and the surface it is being applied to. The exact surface preparation required may vary depending on the specific application and the condition of the surface. However, some common steps in surface preparation for fiberglass mat tissue include cleaning the surface to remove any dirt, grease, or other contaminants, sanding or roughening the surface to create a better bonding surface, and applying a primer or other bonding agent if necessary. It is important to carefully follow the manufacturer's instructions and recommendations for surface preparation to ensure the best results and optimal performance of the fiberglass mat tissue.

- Q: What are the potential health and safety concerns associated with working with fiberglass mat tissue?

- Working with fiberglass mat tissue can pose potential health and safety concerns. The fine fiberglass particles present in the air during handling and cutting can be inhaled, leading to respiratory issues such as irritation, coughing, and difficulty breathing. Prolonged exposure to these particles may also result in long-term lung damage. Additionally, direct skin contact with the fiberglass can cause skin irritation and allergic reactions. Hence, it is important to use appropriate personal protective equipment, such as gloves, masks, and goggles, to minimize these risks and ensure a safe working environment.

Send your message to us

Fiberglass Mat Tissue C-Glass Woven Roving for Pultrusion

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords