Fiberglass Facing Chopped Strand Mat / Fiberglass Mat Roll Fabric CSM Factory in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Chopped Strand Mat /Fiberglass Mat Roll Fabric CSM Factory in China

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Technical Data:

| PRODUCT | TYPE | WEIGHT (G/M2) | WIDTH(MM) | ROLL WIEHGT (KG) | MOISTURE CONTENT(%) | BREAKAGE STRENGTH (N) | BINDER CONTENT(%) |

| EMC100 | E/C-GLASS | 100±30 | 200-3300 | 30-90 | < 0.2 | 170 | 8-13 |

| EMC150 | E/C-GLASS | 150±30 | 200-3300 | 30-90 | < 0.2 | 40 | 5-8 |

| EMC225 | E/C-GLASS | 225±30 | 200-3300 | 30-90 | < 0.2 | 60 | 4-7 |

| EMC300 | E/C-GLASS | 300±30 | 200-3300 | 30-90 | < 0.2 | 90 | 3-6 |

| EMC450 | E/C-GLASS | 450±30 | 200-3300 | 30-90 | < 0.2 | 120 | 2-5 |

| EMC600 | E/C-GLASS | 600±30 | 200-3300 | 30-90 | < 0.2 | 150 | 2-5 |

| EMC900 | E/C-GLASS | 900±30 | 200-3300 | 30-90 | < 0.2 | 180 | 2-5 |

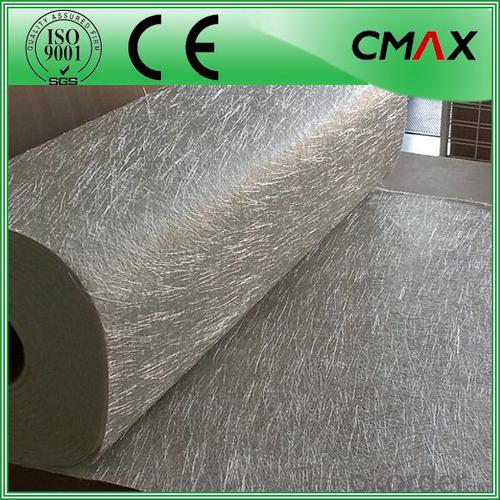

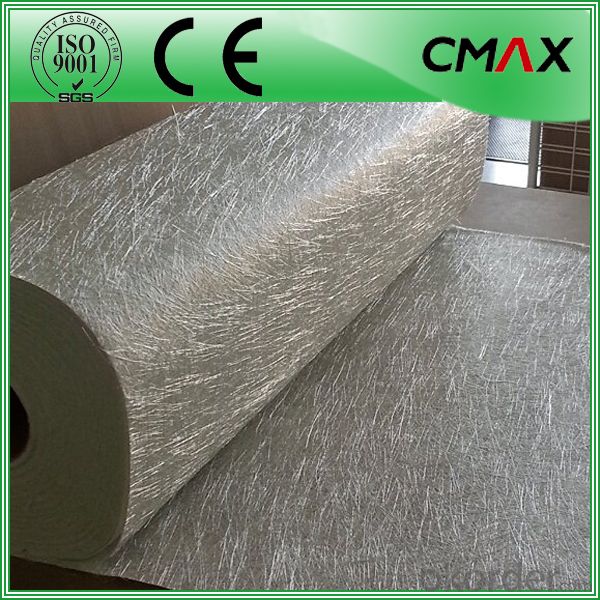

Products Shows:

Certificates:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton.

- Q: How is fiberglass facing used in construction?

- Fiberglass facing is commonly used in construction as a protective layer for insulation materials. It is applied on walls, roofs, and other surfaces to enhance energy efficiency, prevent moisture penetration, and provide thermal insulation. The fiberglass facing acts as a barrier, reflecting heat and reducing heat transfer. Additionally, it adds strength and durability to the insulation material, making it suitable for various construction applications.

- Q: Is it possible to use black fiberglass tissue as a flooring material for a garden or patio?

- <p>Yes, you can use black fiberglass tissue to make flooring for your garden or patio. Fiberglass is known for its durability and resistance to weather, making it a suitable choice for outdoor applications. It's lightweight, easy to install, and can be used in combination with other materials like resin for a more solid and stable surface. However, it's important to ensure that the fiberglass is treated to be resistant to UV rays to prevent degradation over time. Always follow the manufacturer's guidelines for installation and maintenance to ensure the longevity and safety of your flooring.</p>

- Q: This question asks for a comparison between two types of insulation materials: glass fiber and ceramic fiber, highlighting their distinct characteristics and differences.

- <p>Glass fiber and ceramic fiber insulation materials differ in composition, properties, and applications. Glass fiber is made from glass and is known for its high tensile strength, flexibility, and resistance to moisture. It's commonly used in construction and automotive industries. Ceramic fiber, on the other hand, is made from ceramic materials and is characterized by high-temperature resistance, low thermal conductivity, and excellent chemical stability. It's often used in high-temperature industrial applications and aerospace. Additionally, ceramic fiber is generally more expensive than glass fiber due to its superior heat resistance and durability.</p>

- Q: Is it possible to use black fiberglass tissue in the construction or decoration of furniture?

- <p>Yes, black fiberglass tissue can be used for furniture. It is known for its strength, durability, and resistance to corrosion, making it suitable for various applications in furniture design. Fiberglass is often used in outdoor furniture, such as patio sets, due to its weather-resistant properties. It can also be used in modern and contemporary furniture designs for its sleek, matte finish and ability to be molded into various shapes. However, it's important to ensure that the fiberglass is properly treated and finished to avoid any health or safety concerns related to its raw form.</p>

- Q: How should one properly store black fiberglass tissue to maintain its quality and integrity?

- <p>The best way to store black fiberglass tissue is in a cool, dry place, away from direct sunlight and moisture. Store it in a sealed, airtight container to prevent contamination and degradation. Ensure the storage area is well-ventilated to avoid the accumulation of moisture and to protect the tissue from any chemical fumes. Keep it away from heat sources and sharp objects that could cause damage. If possible, label the container with the type of fiberglass and any relevant handling instructions for easy identification and safe handling.</p>

- Q: What is the typical thickness of fiberglass facing?

- The typical thickness of fiberglass facing can vary depending on the specific application and requirements. In general, fiberglass facing is available in thicknesses ranging from 0.5 millimeters to 2 millimeters. Thinner fiberglass facing, around 0.5 to 1 millimeter, is commonly used for lightweight and flexible applications such as insulation and acoustic panels. Thicker fiberglass facing, around 1.5 to 2 millimeters, is often used for more heavy-duty applications where higher strength and durability are required, such as in construction and industrial settings. It is important to consider the specific needs and specifications of a project to determine the appropriate thickness of fiberglass facing to ensure optimal performance and functionality.

- Q: This question asks for the typical cost range of high-quality black fiberglass tissues, which are materials used in various industries.

- <p>The price range for high-quality black fiberglass tissues can vary significantly based on factors such as the manufacturer, thickness, and specific application requirements. Generally, the cost can range from $1 to $10 per square meter for standard grades, while more specialized or high-performance grades may cost between $10 to $50 per square meter. It's important to note that these prices are approximate and can fluctuate due to market conditions, availability, and the quantity purchased. For precise pricing, it's best to contact suppliers directly or check current market listings.</p>

- Q: This question asks about the proper storage methods for black fiberglass paper.

- <p>To store black fiberglass paper, follow these guidelines: Keep it in a cool, dry place away from direct sunlight and moisture. Ensure the storage area is well-ventilated to prevent the buildup of humidity. Store the paper on flat surfaces to avoid bending or creasing. Use protective coverings like plastic sheets to shield the paper from dust and contaminants. If stacking, do not overload as it may cause the bottom layers to compress and damage. Label the storage area clearly to indicate the contents and check regularly for any signs of deterioration.</p>

- Q: What benefits does black fiberglass tissue offer compared to other types of tissues?

- <p>Black fiberglass tissues offer several advantages over other types. They have excellent resistance to high temperatures, making them suitable for use in high-heat environments. They also provide superior electrical insulation properties, which is crucial in electrical applications. Additionally, black fiberglass tissues are known for their chemical resistance, which protects against various chemicals that could degrade other materials. Their strength and durability make them ideal for applications requiring long-lasting performance. Lastly, the black color can provide a more aesthetically pleasing appearance in certain industrial settings.</p>

- Q: What distinguishes different grades of black fiberglass tissues in terms of their properties and applications?

- <p>The differences between various grades of black fiberglass tissues primarily lie in their fiber diameter, weight per unit area, tensile strength, and chemical resistance. Lower grades typically have coarser fibers and lower tensile strength, suitable for general applications like insulation. Higher grades feature finer fibers, higher tensile strength, and better chemical resistance, making them ideal for more demanding applications such as high-temperature environments or chemically aggressive settings. Each grade's specific properties determine its suitability for particular industrial uses.</p>

Send your message to us

Fiberglass Facing Chopped Strand Mat / Fiberglass Mat Roll Fabric CSM Factory in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords