Ferro Silicon Origin Inner Mongolia Province CMBN Fortune500

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

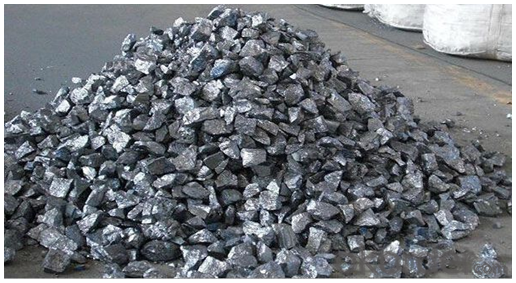

Ferro Silicon Description

Ferro Silicon is a kind of ferroalloy which is composed of ferrum and silicon. Ferro Silicon uses coke, quartz

(or silica) as raw materials and is made by electric furnace. Because silicon and oxygen are easily compound

into SiO2, the ferrosilicon is often used as deoxidizer in steelmaking.

Ferro Silicon Application

1. Fesi 75% is often used as deoxidizer in steel- making.

2. Ferrosilicon also can be used as alloy elements join agent, which is widely used in low alloy steel, non-ferrous metal, bearing steel, heat-resistant steels and electrician silicon-steel.

3. It can be used as a reductant in ferroalloy production and chemical industry.

4. In iron industry it can be used as inoculant and nodulizer.

Specification

Brand | Chemical Composition (%) | ||||||||||

Si | Al | Ca | P | S | C | Fe | |||||

<= | |||||||||||

FeSi75-A | 74.0-80.0 | 1.5 | 1 | 0.035 | 0.02 | 0.2 | Balance | ||||

FeSi75-B | 72.0-80.0 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi72 | 72 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi70 | 70 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi65 | 65.0-72.0 | 2 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi45 | 40.0-47.0 | 2 | 2 | 0.04 | 0.02 | 0.2 | Balance | ||||

Packaging & Shipping

1. Plastic bag(antiproof) +Iron barrel, all adjustable to customer's specific demands.

2. Shipment within 3 working days after production.

Ferro Silicon Size

0-3mm,3-10mm,10-100mm or as the customers’ requirements

Packing

25Kg/bag, 1MT/bag or as your requirements.

Picture

- Q: Carbide blade domestic that tricky point?

- China's carbide cutting tools must be the best cemented carbide in Zhuzhou.

- Q: What is the difference between tungsten cobalt alloy and YG8 and YG6 series cemented carbide?

- YG6, YG6X, YG8, YG8C, YG11C, and so on,YG6 hardness and wear resistance are slightly higher than that of YG8, but strength and toughness are not as good as YG8

- Q: I would like to solder a carbide tool now, what materials do you need to ask for specific methods?

- You need to use the Ya alloy electrode and welding tool first articles to be heated to red (a temperature of about 800~1000 degrees) and then stained with borax flux (in the electrode when need to add) and then work hard alloy or welded tungsten steel tools a turning tool on the lathe tool holder can be cut off in the car turning bracket that is the

- Q: the blade is hard alloy, the processing material is QT600, the plane lower tool margin is 4mm, the speed and the knife

- This belongs to the category of ductile iron, more difficult to process, because the material is hard particles, it is recommended around S=1200 F=400

- Q: What kind of industry can use carbide?

- Blade material used in mechanical processing

- Q: What type of emery grinding machine is 3000/min for grinding carbide turning tools (e.g., YG8.YS8.YT15.YW1, etc.)?

- Diamond grinding wheel, green carborundum wheel can be used. Two, choose one, or choose the former good. Diamond grinding wheel has the advantages of less wear, long life, high productivity and good processing quality, that is, the price is a little more expensive.Grinding wheel: grinding wheel is also called consolidation grinding tool. It is a kind of consolidation grinding tool, which is bonded by the bond agent into a certain shape (most round, central through hole) and has a certain strength. It is generally made up of abrasives, binders and pores. These three parts are often called the three elements of the bonded abrasives. In accordance with the different classification of binders, there are common ceramic (bond) grinding wheel, resin (bond) grinding wheel, rubber (bond) grinding wheel. The grinding wheel is one of the largest amount of abrasives, widely used, when using high-speed rotation can be cylindrical, metal or nonmetal workpiece inner circle, plane and various surface of rough grinding, semi fine grinding and fine grinding and notching and cutting etc.. The characteristics of grinding wheel are mainly determined by abrasive, particle size, bond, hardness, microstructure, shape and size.

- Q: Carbide and carbon steel

- Hard alloy knife, cutting knife, carbon steel is the food, so simple.

- Q: How hard metal is welded with stainless steel?

- Braze welding can be used.Carbide containing tungsten, vanadium and other metals, melting point higher than stainless steel, can be considered

- Q: Several hard alloy cutter lathe with?

- 2 kinds! They are clamp type and welding type.

- Q: The difference between cemented carbide and tungsten.

- The market is usually called tungsten carbide, the two are the same, and the high speed steel called high speed steel. This is the old habit of name of state owned enterprises.

Send your message to us

Ferro Silicon Origin Inner Mongolia Province CMBN Fortune500

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches