Ferro Silicon Popular In Iron Casting CNBM Fortune500

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ferro Silicon Description

Ferro Silicon is a kind of ferroalloy which is composed of ferrum and silicon. Ferro Silicon uses coke, quartz

(or silica) as raw materials and is made by electric furnace. Because silicon and oxygen are easily compound

into SiO2, the ferrosilicon is often used as deoxidizer in steelmaking.

Ferro Silicon Application

1. Fesi 75% is often used as deoxidizer in steel- making.

2. Ferrosilicon also can be used as alloy elements join agent, which is widely used in low alloy steel, non-ferrous metal, bearing steel, heat-resistant steels and electrician silicon-steel.

3. It can be used as a reductant in ferroalloy production and chemical industry.

4. In iron industry it can be used as inoculant and nodulizer.

Specification

Brand | Chemical Composition (%) | ||||||||||

Si | Al | Ca | P | S | C | Fe | |||||

<= | |||||||||||

FeSi75-A | 74.0-80.0 | 1.5 | 1 | 0.035 | 0.02 | 0.2 | Balance | ||||

FeSi75-B | 72.0-80.0 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi72 | 72 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi70 | 70 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi65 | 65.0-72.0 | 2 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi45 | 40.0-47.0 | 2 | 2 | 0.04 | 0.02 | 0.2 | Balance | ||||

Packaging & Shipping

1. Plastic bag(antiproof) +Iron barrel, all adjustable to customer's specific demands.

2. Shipment within 3 working days after production.

Ferro Silicon Size

0-3mm,3-10mm,10-100mm or as the customers’ requirements

Packing

25Kg/bag, 1MT/bag or as your requirements.

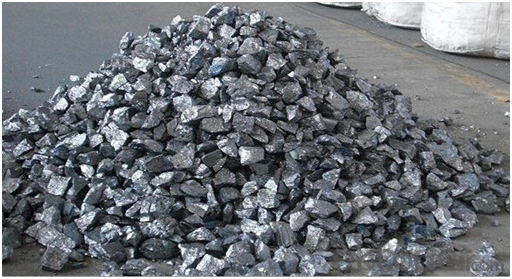

Picture

- Q:What is the difference between the raw and recycled materials of cemented carbides? The more specific, the better

- Raw raw materials are raw materials, recycled materials have been used, and then recycled and re produced, raw materials than recycled materials used, and more pure materials.

- Q:What does P stand for and what is 30? What are its advantages and disadvantages? What is suitable for processing?

- ISO (International Organization for Standardization) will be divided into carbide alloy P, M, K three categories, P class equivalent to China's YT class, the main ingredient is WC-TiC-Co;In order to be processed in different cutting conditions of material grade, in the P class with 01-50 number between that from the highest hardness to a series of alloys for maximum toughness between P30, roughly equivalent to the YT5 of our country;This kind of cemented carbide has the highest strength and best impact resistance in YT (P), but it has poor wear resistance. It is suitable for intermittent roughing of general carbon steel and alloy steel.

- Q:What alloy tool can be used as hard alloy?

- Wire cutting can be cut open. As for what knife car?... I said, man, you have a technical problem

- Q:What are the main causes of wear of high speed steel cutting tools and carbide cutting tools?

- Basically the same, such as plastic wear, flank wear, crater wear, chipping... And so on, each kind of wear phenomenon has the reason, also has some remedial or the improvement measure....High speed steel has lower hardness and abrasion resistance ability is not high, but good toughness, high precision of complex cutting tools, such as broach, gear cutter or the use of high speed steel more, while the standard NC tool are used in a lot of hard alloy or indexable tool..

- Q:Can YG813 carbide cutters be used for cutting stainless steel intermittently? How much is the cutting speed?

- YG type alloy has good impact resistance, can be used to cut stainless steel, cutting speed 80m/min, heightening the concentration of emulsion about 8%, of course, if there is YW alloy better, wear-resistant, heat hardness and hardness are higher

- Q:What are the differences in performance between cemented carbide cutting tools and PCD cutters (polycrystalline diamond)?

- Different cutting objects, PCD cutter durable, but cutting some materials may not be good on the PCD

- Q:The difference between cemented carbide YG 15 and yg12

- K30 YG8N YG8 14.5-14.9 160089.5 is suitable for cast iron, nonferrous metals and their alloys and non-metallic materials processing, not smooth, rough and discontinuous cutting section of rough planing, rough milling, drilling, reaming hole and deep hole. K30 YG8 YG10X 14.3-14.7 220089.5 is suitable for the production of small diameter micro drill, milling cutter, rotary file etc.. K35 YG10X YS2T 14.4-14.6 220091.5 is an ultrafine particle alloy, suitable for low speed rough turning, milling of heat-resistant alloy and titanium alloy, as cutting knives and taps, saw blades, milling cutters are preferred. K30 YS2T YL10.1 14.91900 91.5 has better wear resistance and bending strength, mainly used for the production of extruded bars, suitable for general drills, cutting tools and other wear-resistant parts. K15-K25 YL10.1 14.52200 YL10.2 91.5 has good abrasion resistance and bending strength, mainly used in the production of extruded rods, made of small diameter micro drill tool, watch the whole processing, and other cutting tools and wear parts reamer. K25-K35, YL10.2, YG15, 13.9-14.2 210087 are suitable for high tensile steel bars and steel tubes under high compression, for upsetting, piercing and stamping tools under larger stresses. YG15 YG20 13.4-13.7 250085 is suitable for production of stamping die, stamping parts, such as watch spring plates of musical instruments; die punching battery shell, toothpaste tubes; stamping die small size steel balls, screws, nuts etc; twist drill bits.

- Q:What are the features of cemented carbide YG8 knives?

- So professional, do not understand the normal, YG8 are used for processing pig iron and other artifacts

- Q:CNC alloy milling cutter how to produce?What is the cutting edge of the machine tool?What is the surface coating?What is the cost of plating?Prawns talk about it in detail, I do alloy accessories, I would like to learn some processing methods ~ ~!

- CNC carbide cutter is used to hard alloy powder and powder metallurgy mould after sintering, the hard alloy blade (blank, can not be directly used), then after grinding the surface and edge (this can be installed on the cutter head, and also can be used) in coating the surface to improve its wear resistance, have finished milling blade.The blade is machined with a special blade grinder.

- Q:I'm going to sell carbide cutters. Which industry do you want to sell?

- Don't know whether you go to Suzhou haokai steel metal material limited company to see through

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ferro Silicon Popular In Iron Casting CNBM Fortune500

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords