EXCELLENT HOT-DIP GALVANIZED/ ALUZINC STEEL in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

THICKNESS:0.18mm-1.5mm

WIDTH:900mm-1250mm

COATING MASS:AZ30-AZ150

SPANGLE:Minimized Spangle,Zero Spangle

SURFACE TREATMENT:N0on or Chromated,Non or Oiled,Non or Anti Finger Print

COIL INNER DIAMETER:508mm/610mm

COIL WEIGHT:3mt-7m

Applications of our Galvalume Coil:

Galvalume Coil widely used for roofing products, It is also the ideal base material for Prepainted Steel Coil.

1. roofing

2. gutters

3. unexposed automotive parts

4. appliances

5. furniture

6. outdoor cabinetry

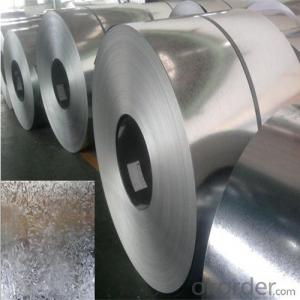

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

- Q: How are steel coils used in the manufacturing of shock absorbers?

- Steel coils are commonly used in the manufacturing of shock absorbers as they provide the necessary strength and flexibility to absorb and dampen shocks and vibrations. These coils are typically placed inside the shock absorber to support the weight of the vehicle and absorb the impact caused by uneven road surfaces. The coiled steel springs compress and expand to absorb the energy from the shocks, ensuring a smoother and more comfortable ride for the vehicle occupants.

- Q: What are the main characteristics of galvanized steel coils?

- The main characteristics of galvanized steel coils include their high corrosion resistance, durability, and ability to withstand extreme weather conditions. They are also known for their excellent formability, making them suitable for various applications in construction, automotive, and manufacturing industries. Additionally, galvanized steel coils have a smooth and shiny appearance due to the zinc coating, which provides aesthetic appeal along with enhanced protection against rust and other damages.

- Q: What are the applications of steel coils?

- Steel coils are utilized across a wide array of industries due to their versatility and durability. The construction industry, in particular, heavily relies on steel coils for structural purposes. These coils can be shaped and molded into different sizes and forms to create essential components like beams, columns, and other structural elements needed in buildings, bridges, and infrastructure projects. Another significant field that benefits from steel coils is the automobile manufacturing industry. Steel coils are instrumental in producing various parts and components of vehicles, including body panels, chassis, frames, and engine parts. The exceptional strength and durability of steel make it an ideal material for ensuring the safety and longevity of automobiles. Moreover, steel coils play a crucial role in the production of household appliances such as refrigerators, washing machines, and stoves. Steel's versatility allows it to be easily molded and shaped into different configurations, making it suitable for various appliance components. In the energy sector, steel coils find extensive use in the manufacturing of power generation equipment and pipelines. Turbines, generators, and other equipment used in power plants are made from steel coils. Additionally, steel coils are employed in constructing pipelines for the transportation of oil, gas, and other fluids. Furthermore, steel coils are widely employed in the fabrication of storage tanks, industrial machinery, and agricultural equipment. They are also utilized in the production of furniture, shelving units, and various metal products. In summary, steel coils play a vital role in numerous industries, including construction, automotive, appliance manufacturing, energy, and others. The strength, durability, and versatility of steel make it an indispensable material for both structural and functional purposes.

- Q: I'm planning to buy a pair of Doc Marten boots but I want some steel toed ones. I don't know if all of them are steel toed, or only some of them, or what?

- Steel Toe Doc Martens

- Q: How are steel coils handled during loading and unloading?

- Steel coils are typically handled using cranes, forklifts, or coil hooks during loading and unloading. The coils are carefully lifted, secured, and transported to their respective destinations. Special attention is paid to ensure proper balance, stability, and safety measures are followed to prevent any damage or accidents during the process.

- Q: i see a lot of connexes say repair only with corten steel. what is the difference between corten steel and regular steel. and if i was going to stick weld it what type of electrode would i use?and while i'm at it what is the best electrode to use when welding galvenized steel?

- 6010 and 6011 Electrodes for welding galvenized steel. Weathering steel, best-known under the trademark COR-TEN steel and sometimes written without the hyphen as Corten steel, is a group of steel alloys which were developed to obviate the need for painting, and form a stable rust-like appearance if exposed to the weather for several years. The corrosion-retarding effect of the protective layer is produced by the particular distribution and concentration of alloying elements in it. The layer protecting the surface develops and regenerates continuously when subjected to the influence of the weather. In other words, the steel is allowed to rust in order to form the 'protective' coating. For welding corten steel: 1A.W.S ClassificationE 7018 - 1AWS A 5 - 1 - 78 2IS classificationE 5424 JXIS 814 (Part I II)H 3BS classificationE 51.54 B 12 17HBs 639 - 1976

- Q: Can you weld copper or brass to steel?

- GTAW,Weld Copper to steel, RN-60. Silver Braze Copper to Steel, Grade 4 Silver.

- Q: Can steel coils be used in the production of consumer goods?

- Yes, steel coils can be used in the production of consumer goods. Steel coils are versatile and commonly used in various industries, including consumer goods manufacturing. They are often used as raw materials in the production of appliances, automotive parts, construction materials, furniture, and packaging. The durability and strength of steel coils make them suitable for these applications, ensuring the quality and longevity of the consumer goods produced.

- Q: What are the dimensions of steel coils used in the mining equipment industry?

- The dimensions of steel coils utilized in the mining equipment sector may differ depending on the particular application and demands. Nevertheless, there are frequently employed standard dimensions. Typically, the width of steel coils used in the mining equipment industry can range from 600mm to over 2000mm. This allows for adaptability in the manufacturing process and guarantees that the coils can be customized to fit different equipment sizes and specifications. Regarding thickness, steel coils employed in mining equipment can range from 1.5mm to 20mm or more. The specific thickness is determined by factors such as equipment type, intended usage, and required durability level. The length of steel coils used in the mining equipment industry can also vary, but usually falls within the range of 1000mm to 6000mm. Once again, this offers flexibility in the manufacturing process and ensures that the coils can be cut to suit the exact requirements of the equipment being produced. It is essential to acknowledge that these dimensions are not fixed and can be tailored to meet the specific needs of the mining equipment sector. Manufacturers and suppliers in the industry can often provide coils in different sizes and dimensions to accommodate the wide array of equipment used in mining operations.

- Q: What are the different grades of steel used in coil production?

- There are various grades of steel used in coil production, including low carbon steel, high carbon steel, stainless steel, and advanced high-strength steel. These grades are chosen based on the specific requirements of the application, such as strength, corrosion resistance, and formability.

Send your message to us

EXCELLENT HOT-DIP GALVANIZED/ ALUZINC STEEL in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords