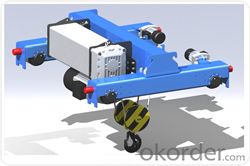

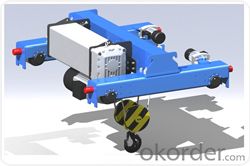

Europe style double rail electric hoist

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Based on bring in and assimilating foreign advanced technology, this type of electric hoist trolley takes modular design theories as guidance, uses modern computer technology as means, introduces optimized and reliable design method, which is new type of hoist made by employing inport configuration, new material and technology and has features in light-weight, generalizing, energy-conservation and environmental protection, maintenance free and high technology content.

This type Europe standard electric hoist applied in industry of machinery production, assembling, petrochemicals, warehouse logistics, electric power construction, papermaking and railways.

Design, production and inspection carry out the last issued relevant national standard,equivalently adopts some foreign criteria including FEM, DIN and IEC . As the core component of driving mechanism, reducer gear pair with hard tooth surface and high accuracy, together with steel reel, forged wheel and variable-frequency speed regulating system , which makes this type of crane become renewal product of traditional .

Features:

1.High Efficiency and Make the Most of space

2.Accurate orientation,highly-efficient operation,improved logistics efficiency.

3.Safe and reliable,monitored operation,easy maintenance.

4.Modularized desigh,low maintenance cost,perfect spare parts and components services

Product Features:Job level is high,can be applied to all kinds of bad place,and the price is good. Note: can be according to your request make non-standard products.

Technical Data:

S.W.L (kg) | FEM | ISO | Hoisting height(m) | Hoisting Speed(m/min) | Traveling Speed(m/min) | Size H (mm) | Size C (mm) |

2000 | 3M | M6 | 6/9/12/18 | 0.8/5.0 | 5~20 | 463 | 350 |

3200 | 2M | M5 | 6/9/12/18 | 0.8/5.0 | 5~20 | 463 | 350 |

5000 | 2M | M5 | 6/9/12/18 | 0.8/5.0 | 5~20 | 463 | 350 |

6300 | 1AM | M4 | 6/9/12/18 | 0.8/5.0 | 5~20 | 463 | 350 |

8000 | 3M | M6 | 6/9/12/18 | 0.8/5.0 | 5~20 | 580 | 563 |

10000 | 1AM | M4 | 6/9/12/18 | 1.0/6.3 | 5~20 | 580 | 563 |

10000 | 2M | M5 | 6/9/12/18 | 0.8/5.0 | 5~20 | 580 | 563 |

10000 | 3M | M6 | 6/9/12/18 | 0.66/4.0 | 5~20 | 580 | 563 |

12500 | 1AM | M4 | 6/9/12/18 | 0.8/5.0 | 5~20 | 580 | 563 |

12500 | 1AM | M4 | 6/9/12/18 | 1.0/6.3 | 5~20 | 679 | 700 |

12500 | 2M | M5 | 6/9/12/18 | 0.6/4.0 | 5~20 | 679 | 700 |

16000 | 2M | M5 | 6/9/12/18 | 0.66/4.0 | 5~20 | 679 | 700 |

20000 | 1AM | M4 | 6/9/12/18 | 0.66/4.0 | 5~20 | 679 | 700 |

20000 | 2M | M5 | 6/9/12/18 | 0.53/3.4 | 5~20 | 679 | 700 |

20000 | 3M | M6 | 6/9/12/18 | 1.0/4.2 | 5~20 | 864 | 1000 |

25000 | 1AM | M4 | 6/9/12/18 | 0.53/3.4 | 5~20 | 864 | 1000 |

25000 | 3M | M6 | 6/9/12/18 | 0.8/3.3 | 5~20 | 864 | 1000 |

25000 | 2M | M5 | 6/9/12/18 | 1.0/4.2 | 5~20 | 864 | 1000 |

32000 | 2M | M5 | 6/9/12/18 | 0.8/3.3 | 5~20 | 864 | 1000 |

32000 | 2M | M5 | 6/9/12/18 | 0~4.9 | 5~20 | 1023 | 950 |

40000 | 1AM | M4 | 6/9/12/18 | 0~4.9 | 5~20 | 1023 | 950 |

50000 | 2M | M5 | 6/9/12/18 | 0~3.2 | 5~20 | 1023 | 950 |

50000 | 1AM | M4 | 6/9/12/18 | 0~4.1 | 5~20 | 1023 | 950 |

63000 | 1AM | M4 | 6/9/12/18 | 0~3.2 | 5~20 | 1023 | 950 |

63000 | 2M | M5 | 6/9/12/18 | 0~2.4 | 5~20 | 1023 | 1110 |

80000 | 1AM | M4 | 6/9/12/18 | 0~2.4 | 5~20 | 1023 | 1110 |

- Q: This question asks for a list of various types of lifting equipment commonly used in the construction industry.

- <p>In construction, various types of lifting equipment are utilized to move heavy materials and structures. These include cranes such as tower cranes, mobile cranes, and crawler cranes, which are versatile and can lift heavy loads to significant heights. Forklifts are used for lifting and moving materials over short distances. Telescopic handlers, also known as cherry pickers, provide both lifting and access capabilities. Hoists are used for lifting smaller loads and are often found in workshops or on construction sites. Derricks are fixed structures used for lifting heavy loads in a specific area. Lifting slings and shackles are used in conjunction with cranes and hoists to secure loads. Finally, aerial work platforms, like scissor lifts and boom lifts, provide elevated access for workers and materials. Each type of lifting equipment serves a specific purpose and is chosen based on the nature of the construction project and the weight and size of the loads to be moved.</p>

- Q: Safe use of construction elevator

- 1. Construction enterprises must establish and improve the construction lifter of all kinds of management system, the implementation of the professional institutions and management personnel, clear the safe use and management responsibility system at various levels. The driver of the elevator should be trained by the competent department of the relevant administrative department for the training of qualified personnel. The driver should do the routine inspection, namely, when the elevator is first run, each class should be free and full of trial operation. 4. Establish and implement the system of regular inspection and maintenance, each week or each ten-day of elevator to conduct a comprehensive inspection, to find out the hidden dangers in accordance with the "armed" principle to carry out the rectification. After the rectification must be checked and confirmed by the relevant personnel, the safety requirement will be used.

- Q: This question asks for the steps or procedures to keep a building hoist in good working condition.

- <p>Maintaining a building hoist involves regular inspections, lubrication, and repairs. Ensure all safety features are operational and that the hoist is clean and free of debris. Check cables for wear and replace them if necessary. Lubricate moving parts as per the manufacturer's recommendations. Inspect the electrical system for any signs of damage or wear. Regularly test the hoist's load capacity and emergency stop functions. Keep a maintenance log to track all inspections and repairs. If any issues are identified, address them promptly to prevent accidents and ensure the hoist operates safely and efficiently.</p>

- Q: Why is the construction elevator not up to the roof

- Construction elevators are often called construction elevators, but construction lifts include a broader definition, and construction platforms are part of the construction elevator series. Simple construction elevator is by car, driving mechanism, standard section, attached to the wall, chassis, fence, electrical system and so on several parts, manned cargo construction machinery is a frequently used in construction, because of its unique enclosure structure make it take up both comfort and safety, construction elevator is usually used with tower crane on the construction site, the average load in 1-3 tons, running speed is 1 to 60 m/min. The construction elevator of our country is more and more mature, and gradually goes to the international.

- Q: What's going on with the decline in construction lift

- Check whether the brake contactor and normal, contactor adhesion conditions will decline, brake pads have the problem not only rise to fall, fall in the same slide. If the contactor is ok, you can see that there is a groove on the brake pad, and it is only replaced if the brake is not damaged, such as cracking. If it's a frequency conversion elevator, if you're down, see if the converter has any fault code, if you have a consulting manufacturer. The assumption is that the anchuan frequency converter, which may be a real SE failure, means that the timing error is not normal for controlling the contact of the receiver.

- Q: Is it possible for a building hoist to lift more than one object simultaneously?

- <p>Yes, a building hoist can lift multiple objects at once, provided the combined weight does not exceed the hoist's maximum load capacity. The hoist's design and specifications will dictate how many and what types of objects can be lifted simultaneously. It's crucial to follow the manufacturer's guidelines to ensure safety and prevent damage to the hoist or the objects being lifted.</p>

- Q: The maximum allowable deviation of the vertical is the vertical degree when the construction elevator is installed

- 5 kinds of circumstances. 1: the height of the elevator guide frame is less than 70 meters, and the vertical deviation should not be greater than one in 1000 of the height of the guide frame. (assuming the rail frame is 70 meters high, the deviation cannot be greater than 70mm) 2: the rail frame is greater than 70 meters and is less than 100 meters, and the deviation is less than or equal to 70 mm. 3: the guide frame is larger than 100 meters and is less than 150 meters. The deviation is less than or equal to 90 mm. 4: the guide frame is larger than 150 meters is less than or equal to 200 meters. The deviation is less than or equal to 110 mm. 5: the guide frame is greater than 200 meters, and the deviation is less than 130 mm. This is based on the requirement of 5.2.2.1 from GB10054 to 2005. (it used to be a direct copy.)

- Q: This question asks for a comparison of the benefits and drawbacks of employing lifting equipment in the construction industry.

- <p>Advantages of using lifting equipment in construction include increased efficiency, reduced manual labor, and the ability to handle heavy loads safely. It can also improve safety by reducing the risk of injury from lifting heavy objects manually. Additionally, it allows for faster construction times and can access hard-to-reach areas. Disadvantages include high initial costs for purchasing or renting the equipment, potential for mechanical failure, and the need for skilled operators. There is also a risk of accidents if the equipment is not used properly, and it may require more maintenance and training for staff.</p>

- Q: The tower crane is on a surface with the construction elevator, and only 2 or 3 meters away. Is that allowed

- There are no rules for the distance between tower crane and construction elevator, but note the following points: (1) the foundation of the tower crane and the construction elevator cannot affect each other; (2) the construction elevator shall not be higher than the tower crane. (3) the location of the elevator shall not be blocked by the position of the construction elevator; (4) the use of the same circuit and the same distribution box with the construction elevator shall not be used by the tower crane. The distance between the tower crane and the construction elevator can be anywhere, as long as the above aspects are met.

- Q: The elevator is banned from using elevators for more than a class of high winds

- According to the safety requirement is level 6, please adopt!

Send your message to us

Europe style double rail electric hoist

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords