ERW steel pipe with high quality and cerficate

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 watt

- Supply Capability:

- 8000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Welded Steel Tube:

Welded Steel Tube is formed by drawing a solid billet over a piercing rod to create the hollow shell. We are company that have many years experience and professional manager team and engineer team and sales team, sure we will provide you high quality of welded pipe and professioanl service.

2、Main Features of the Welded Steel Tube:

• High manufacturing accuracy

• The higher strength

• The small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Satisfy price

3、Welded Steel Tube Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Welded Steel Tube:

①How is the quality of your products?

Our products are strictly in accordance with international and domestic standard. We test on every pipe before delivery. Any quality certification or testing report you want to see, please tell us.

Guaranteed: If products’ quality is not in accordance with description as we provide or the promise before you place order, we promise 100% refund.

②How about the price?

Yes, we are factory and be capable of offering you the lowest price. One of our policy is that “ to save time and be absolutely honest with our business relationship, we quote as low as possible for every client, and discount can be given according to the quantity”, if you are interested in bargain and dissatisfy our factory price, just don’t waste your time. Our quotation is professional.

③Why should you choose us?

Choice happens because of our quality and price. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), fast goods delivery, outstanding customer solution proposals. Our service formula: good quality + good price + good service=customer’s trust.

SGS test is available. Customer inspection before shipping is welcome. Third party inspection is OK.

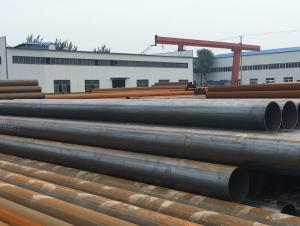

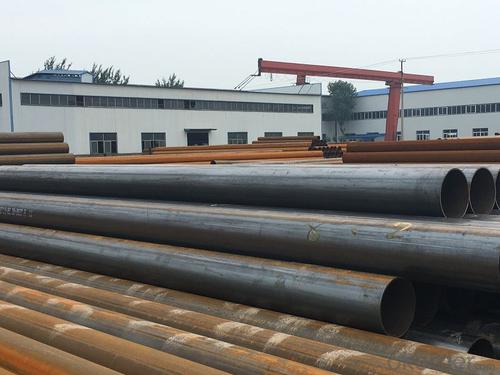

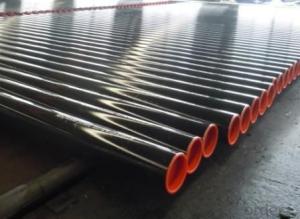

6、 Welded Steel Tube Images:

- Q: Can steel pipes be used for the construction of high-rise buildings?

- Yes, steel pipes can be used for the construction of high-rise buildings. Steel pipes are commonly used in the construction industry due to their strength, durability, and ability to withstand high pressure and heavy loads. They are often used in the structural framework of high-rise buildings to provide structural support and stability. Additionally, steel pipes can be easily fabricated and installed, making them a suitable choice for constructing tall and complex structures.

- Q: What are the different methods of joining steel pipes for steam applications?

- There are several methods of joining steel pipes for steam applications, including threading, welding, and using mechanical couplings. Threading involves screwing the pipes together using male and female threads, which provides a secure connection. Welding involves fusing the ends of the pipes together using heat, creating a strong and permanent bond. Mechanical couplings use a mechanical device to join the pipes, such as a clamp or compression fitting, which allows for easy disassembly and reassembly if needed. Each method has its advantages and is chosen based on the specific requirements of the steam application.

- Q: How are steel pipes used in the oil and gas industry?

- Steel pipes are widely used in the oil and gas industry for various purposes. They are primarily used for transporting and distributing oil and gas from extraction sites to refineries and end consumers. Steel pipes are also used in drilling operations, where they are utilized as casing and tubing to extract oil and gas from wells. Additionally, steel pipes are employed in the construction of storage tanks, pipelines, and other infrastructure required for the production, processing, and transportation of oil and gas. Overall, steel pipes play a crucial role in ensuring the efficient and safe operation of the oil and gas industry.

- Q: What is the difference between steel pipes and HDPE pipes?

- Steel pipes are made from a durable alloy of iron and carbon, while HDPE pipes are made from high-density polyethylene, a strong and flexible plastic material. Steel pipes are generally heavier and more rigid, making them suitable for high-pressure applications and structural support. HDPE pipes, on the other hand, are lighter, more flexible, and resistant to corrosion, making them ideal for underground and aboveground installations in various industries including water supply, gas distribution, and sewage systems.

- Q: Can steel pipes be used for underground sewage treatment plants?

- Yes, steel pipes can indeed be used for underground sewage treatment plants. Steel pipes are commonly used in underground applications due to their durability, strength, and resistance to corrosion. They are capable of withstanding the harsh underground environment and can efficiently transport sewage from one area to another within the treatment plant. Moreover, steel pipes can be customized to meet the specific requirements of the sewage treatment plant, such as different diameters and wall thicknesses, ensuring proper flow and drainage. Additionally, steel pipes can be coated or lined with protective materials to enhance corrosion resistance, further extending their lifespan. Overall, steel pipes are a reliable and suitable choice for underground sewage treatment plants.

- Q: Why should the weak electricity be pre buried with galvanized steel pipe?

- Galvanized steel pipe with hot-dip galvanizing or galvanized coating on it. Galvanizing can increase the corrosion resistance and prolong the service life of the steel pipe. The use of galvanized pipe is very wide, except for water, gas, oil and other general low pressure fluid pipeline, is used in petroleum industry especially offshore oil well pipe and oil pipe, chemical coking equipment oil heater, cooler, oil pipe exchanger for coal distillation, and support piles, Zhanqiao mine tunnel the tubes.

- Q: How are steel pipes used in underground drainage systems?

- Steel pipes are commonly used in underground drainage systems due to their durability and strength. They are used to transport wastewater, stormwater, and other liquids away from buildings and infrastructure to a designated discharge point. The steel pipes provide a reliable and long-lasting solution, ensuring the efficient flow of water and preventing any potential leaks or damage to the surrounding environment.

- Q: What are the different methods of cutting steel pipes?

- The different methods of cutting steel pipes include using a hacksaw, pipe cutter, angle grinder with a cutting disc, reciprocating saw, plasma cutter, or oxy-fuel torch.

- Q: How are steel pipes protected against ultraviolet radiation?

- Steel pipes are typically protected against ultraviolet radiation through the application of specialized coatings or paints that contain UV inhibitors. These coatings create a barrier between the steel surface and the harmful UV rays, preventing the degradation and discoloration of the pipes. Additionally, some steel pipes may be wrapped with UV-resistant tape or sleeves for added protection against prolonged exposure to sunlight.

- Q: How are steel pipes used in HVAC systems?

- Steel pipes are commonly used in HVAC systems for various purposes. They are used for transporting fluids such as water, steam, and refrigerant throughout the system. These pipes are durable and resistant to high temperatures and pressures, making them suitable for the demanding conditions of HVAC applications. They are used for distributing and circulating the heated or cooled air, as well as for connecting different components of the system, including boilers, chillers, heat exchangers, and air handlers. Additionally, steel pipes are often used for ventilation and exhaust purposes in HVAC systems.

Send your message to us

ERW steel pipe with high quality and cerficate

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 watt

- Supply Capability:

- 8000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords