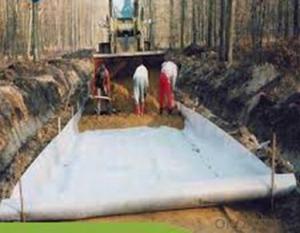

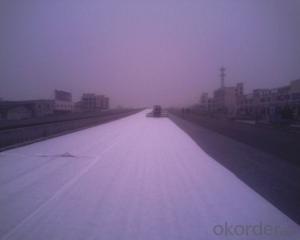

Non Woven Geotextile Membrane for Engineering in Road, Railway, Highway, and Tunnel Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Engineering Fiber for Road Railway Highway Tunnel

Made from polypropylene or polyester fiber by melting, spinning and anti-static treatment.

Specification of Engineering Fiber for Road Railway Highway Tunnel

I. Cement concrete fiber-PP net fiber

2. Cement mortar fiber-PP single fiber

3. Asphalt concrete fiber-PET fiber

Property of Engineering Fiber for Road Railway Highway Tunnel

I. High binding force with concrete

2. Prevent sedimentation and cracks

3. High tensile strength

4. High safety factor

Application of Engineering Fiber for Road Railway Highway Tunnel

I. Anti-crack in industrial and civil buildings

2. Basement and underground works, which require high waterproof and anti-crack performance

Seawalls dam and other salt water projects

3. AlI kinds of precast concrete products

4. Concrete in highway, bridge, tunnel, airport ground

5. Chemical plants which require high anti-alkaline and chemical resistance

Production Standard:

JT/T 525-2004

- Q: Production of geomembrane equipment which are such as the production of geotextile need to press machine, open charter, carding machine, etc.

- Mixing machine, screw extruder, heating die, circulating fan, traction machine, into a roll machine.

- Q: How is this set of water quotas? More

- Hello, I am specializing in the production of geotextiles and other geotextile materials,

- Q: What are the factors that affect the effectiveness of geotextiles in erosion control?

- The effectiveness of geotextiles in erosion control is influenced by several factors. Firstly, the material and quality of the geotextile itself play a significant role. Geotextiles with higher tensile strength and durability are more effective in preventing erosion. Secondly, the design and installation of the geotextile are crucial. Proper placement and anchoring techniques ensure that the geotextile remains in place and functions effectively. The type and intensity of the erosive forces also impact the effectiveness of geotextiles. Factors such as water flow rate, soil type, slope gradient, and vegetation cover can affect how well the geotextile mitigates erosion. Additionally, the maintenance and regular inspection of the geotextile are important for its long-term effectiveness. Overall, a combination of material quality, proper installation, and consideration of site-specific conditions contribute to the effectiveness of geotextiles in erosion control.

- Q: How do geotextiles affect soil settlement?

- Geotextiles can significantly affect soil settlement by providing reinforcement and stabilization. These synthetic materials help distribute the loads applied to the soil, reducing settlement and preventing soil movement. They also improve drainage and filtration, allowing water to pass through the soil more easily, minimizing the potential for settlement due to water accumulation. Overall, geotextiles play a crucial role in controlling soil settlement and maintaining the stability of various structures.

- Q: Sponge city sunken green land in the drilling drainage jacket how to set the amount of geotextile

- Need plastic blind ditch, complete specifications, collar Xiang new materials for your answer

- Q: What are the geotechnical test test items for highway engineering? The

- Unit area weight or tensile strength, CBR burst strength, these two are the most basic, the other is not too important

- Q: Can geotextiles be used in coastal erosion control in beach nourishment projects?

- Yes, geotextiles can be used in coastal erosion control in beach nourishment projects. Geotextiles are permeable fabrics that can act as a filter and reinforcement, helping to stabilize the sand and prevent erosion. They can be used as a protective layer between the beach sediment and the underlying soil, preventing sand washout and promoting beach stability. Geotextiles are commonly employed in beach nourishment projects to enhance coastal resilience and mitigate erosion.

- Q: How do geotextiles improve the performance of foundations?

- Geotextiles improve the performance of foundations by providing reinforcement, filtration, and separation. They help distribute loads more evenly, increase the load-bearing capacity, and reduce settlement. Additionally, geotextiles prevent the mixing of different soil layers, control erosion, and enhance drainage, ultimately increasing the stability and longevity of the foundation.

- Q: How do geotextiles improve the performance of geomembranes?

- Geotextiles improve the performance of geomembranes by providing separation, filtration, and reinforcement functions. They prevent the mixing of different soil layers, enhance drainage, and distribute loads more evenly. Additionally, geotextiles protect the geomembranes from punctures and abrasions, thereby increasing their durability and lifespan.

- Q: Do you need to use geotextile for construction site? Mainly used where?

- Underground garage roof green

Send your message to us

Non Woven Geotextile Membrane for Engineering in Road, Railway, Highway, and Tunnel Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords