Electrolytic Tinplate Coils or Sheets for Metal Tin Cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Electrolytic Tinplate Coils or Sheets for Metal Tin Cans Description

Tinplate is a thin steel sheet coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solderability, and weldability.

2.Main Features of the Electrolytic Tinplate Coils or Sheets for Metal Tin Cans

Tinplate is used for making all types of containers such as food cans, beverage cans, 18-liter cans, and artistic cans. Its applications are not limited to containers; recently, tinplate has also been used for making electrical machinery parts and many other products.

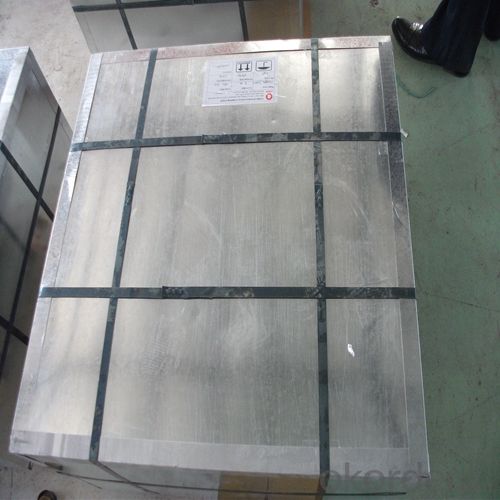

3.Electrolytic Tinplate Coils or Sheets for Metal Tin Cans Images

4.Electrolytic Tinplate Coils or Sheets for Metal Tin Cans Specification

Specification of :

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Electrolytic Tinplate Coils or Sheets for Metal Tin Cans

- How are the tinplates specified?

The tinplates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q: How thick is tinplate?

- Tinplate typically has a thickness ranging from 0.13 to 0.49 millimeters.

- Q: Can tinplate be customized with different designs or logos?

- Yes, tinplate can be easily customized with different designs or logos. Its smooth surface allows for high-quality printing, making it an ideal choice for branding and promotional purposes.

- Q: What are the welding methods used for tinplate?

- The welding methods commonly used for tinplate include spot welding, seam welding, and resistance welding.

- Q: What kind of metal material is tinplate? How much is the current price per ton?

- Tinplate originated in Bohemia (now Czech and Slovakia). The land has been rich in metal technology since ancient times, and know how to use water power in the manufacture of machinery, from fourteenth Century onwards began to produce tinplate. For a long, long time, it has been the main source of tinplate in the world. Tin was mainly used for making tableware and drinking utensils.

- Q: What are the main competitors of tinplate in the packaging industry?

- The main competitors of tinplate in the packaging industry are aluminum, glass, and plastic.

- Q: Can tinplate be used for packaging wine or spirits?

- Yes, tinplate can be used for packaging wine or spirits. Tinplate is a durable and corrosion-resistant material that provides excellent protection against light, oxygen, and moisture. It also offers a classic and premium appearance, making it a popular choice for wine and spirits packaging.

- Q: What are the different testing methods for tinplate packaging?

- Some of the different testing methods for tinplate packaging include visual inspection, leak testing, drop testing, compression testing, and corrosion resistance testing.

- Q: What are the main challenges in the disposal of tinplate products?

- The main challenges in the disposal of tinplate products include the separation of tin from steel during recycling, as well as the proper handling and disposal of hazardous materials such as coatings or residual contents that may be present on the tinplate. Additionally, ensuring effective collection and recycling systems, as well as promoting consumer awareness and participation in recycling programs, pose significant challenges in the disposal of tinplate products.

- Q: What is the purpose of tinplate coating?

- The purpose of tinplate coating is to provide a protective layer of tin on the surface of steel, preventing corrosion and enhancing the durability and longevity of the metal.

- Q: Can tinplate be used for energy storage applications?

- Yes, tinplate can be used for energy storage applications. Tinplate, which is a thin steel sheet coated with a layer of tin, offers good corrosion resistance and durability, making it suitable for various energy storage purposes. It can be used in the construction of batteries, capacitors, and other energy storage devices. Additionally, tinplate's ability to maintain airtightness and prevent moisture penetration makes it a reliable choice for storing and preserving energy.

Send your message to us

Electrolytic Tinplate Coils or Sheets for Metal Tin Cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords