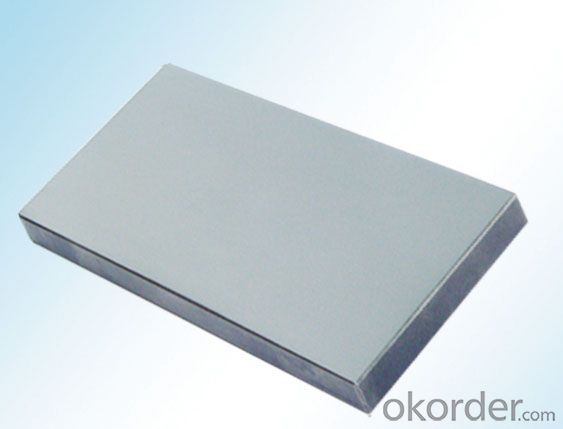

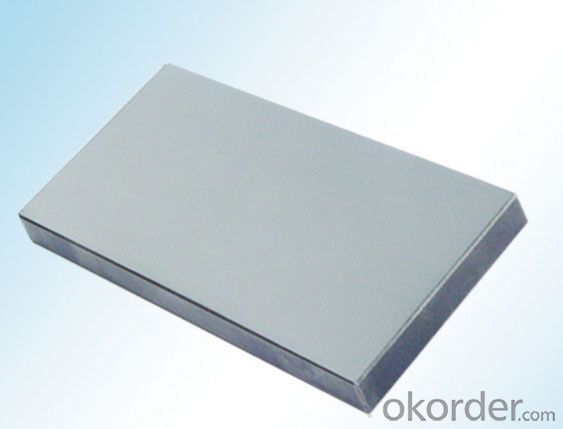

Electrical Cabinet Making Aluzinc 1.5mm Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Electrical Cabinet Making Aluzinc 1.5mm Steel Sheet

Quick Details

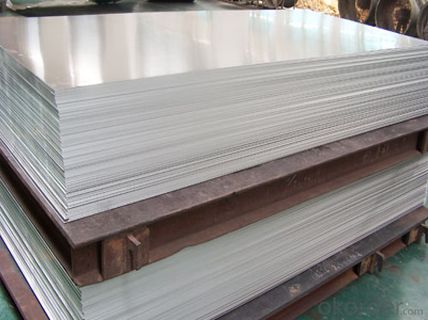

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DC51D+AZ,DX51D+AZ,SGLCC

Thickness: 0.13mm--3.0mm

Model Number:DC51D+AZ,DX51D+AZ,SGLCC

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Galvanized, Chromated, Oiled, Anti-finger Print

Application: Architecture,Auto Industry,Appliances Industry,Industrial Instruments

Width: 600mm--1250mm

Length: Any Length Based on Coil Weight or by Required

Product Name: Electrical Cabinet Making Aluzinc 1.5mm Steel Sheet

Key Word: Aluzinc 1.5mm

Spangle: Mini Spangle

Thickness of coating: AZ30--AZ150

Coil I.D.: 508/610mm

Coil Weight: 3--10MT

Supply Ability: 700,000 MT per Year

Substrate Steel: Cold Rolled

Steel Grade:DC51D+AZ,DX51D+AZ,SGLCC

Pack and Delivery

| Packaging Details: | Mill's Standard Export Sea-worthy Packing for Electrical Cabinet Making Aluzinc 1.5mm Steel Sheet |

|---|---|

| Delivery Detail: | 15~30 Days for Electrical Cabinet Making Aluzinc 1.5mm Steel |

FAQ

1.Q: Do you have the Galvalume Steel Coils in stock?

A: We have Galvalume Steel Coils in stock ,also can produce according to your order.

2.Q: Are you professional at your products?

A: have over 10-year experience on service end-user and knows well about characters and usage of material, professional suggestion about products can be offered when you needed.

Picture

- Q: How are steel coils welded together?

- Different methods can be employed to weld steel coils together, depending on the specific requirements and the type of steel being used. Electric resistance welding (ERW) is a common method where an electric current is utilized to generate heat in the coils, melting their edges. Pressure is then applied to join them together. ERW is a cost-effective and speedy technique for welding steel coils. Thinner steel coils are often welded using high-frequency induction welding (HFIW). This involves the use of an induction coil to produce an alternating magnetic field, inducing an electric current in the coils. The resistance of the coils to this current generates heat, causing the edges to melt and form a weld. For thicker and heavier steel coils, submerged arc welding (SAW) is commonly employed. This technique utilizes a granular flux and a continuous electrode that is fed into the weld area. The flux melts, creating a protective shield for the weld pool, while the electrode melts to form the weld. SAW is a robust and efficient method for welding steel coils. In addition to these methods, laser welding and gas metal arc welding (GMAW) can also be utilized for welding steel coils. Laser welding offers high precision and speed, while GMAW, also known as MIG welding, utilizes an electric arc between a consumable wire electrode and the steel coils to create a weld. Irrespective of the welding method employed, successful welding of steel coils hinges on proper edge preparation, maintenance of appropriate heat and pressure levels, and the use of correct welding techniques.

- Q: If needed for Defence could a stainless steel sword kill someone my buddy wanted this sword for Defece after it is sharpend here is a picture

- Ya it could kill someone if it was sharpened enough but from experience stainless steel swords don't get as sharp as Carbon or higher grade steel. Not to mention it would probably bend if you hit someone with it all the way. Hell the one I let some people who were chopping a bush ( just a normal bush ) they were playing around and it got bent. I'm going to say I can't suggest a stainless steel sword for anything other then handing on your wall. Not even going into the whole If you use a sword for self defense is it considered self defense? debate. It's a sketchy situation not to mention you would need training with a sword to actually use it without it just getting brushed off.

- Q: How are steel coils inspected for oil or rust residues using chemical analysis?

- Steel coils can be inspected for oil or rust residues using chemical analysis techniques. One of the commonly used methods is Fourier transform infrared spectroscopy (FTIR). In this technique, a small sample of the steel coil is taken and subjected to infrared radiation. The infrared spectrum obtained is then analyzed to identify the presence of specific chemical bonds that are characteristic of oil or rust residues. For detecting oil residues, a common approach is to use the peak at around 2920 cm-1 in the FTIR spectrum, which corresponds to the C-H stretching vibration in hydrocarbon chains. If this peak is observed, it indicates the presence of oil residues on the steel coil. To identify rust residues, the FTIR spectrum is analyzed for the presence of characteristic peaks corresponding to iron oxide or hydroxide compounds. For example, the presence of a peak at around 560 cm-1 suggests the presence of iron oxide (FeO) or iron hydroxide (Fe(OH)3). In addition to FTIR analysis, other chemical analysis techniques can also be utilized, such as X-ray fluorescence spectroscopy (XRF) or energy-dispersive X-ray spectroscopy (EDX). These techniques can provide elemental composition information, allowing for the identification of specific elements associated with oil or rust residues, such as carbon or iron. Overall, the chemical analysis of steel coils for oil or rust residues provides a reliable and accurate method to ensure the quality and cleanliness of the coils before further processing or usage.

- Q: How are steel coils shipped internationally?

- Steel coils are typically shipped internationally using cargo ships or freight trains. The coils are securely loaded onto flatbed or container vessels, ensuring they are properly secured to prevent any damage during transportation. This method allows for efficient and cost-effective transportation of large quantities of steel coils across the globe.

- Q: How are steel coils inspected for surface defects?

- Steel coils are inspected for surface defects using various methods such as visual inspection, magnetic particle inspection, eddy current testing, and ultrasonic testing. These techniques allow for a thorough examination of the coil's surface, identifying any cracks, scratches, dents, or other imperfections that may affect the quality of the steel.

- Q: Steel Strings on your guitar or nylons? Why?

- Kind of a silly question. I use steel strings on my steel string guitars and nylon strings on my classical guitar. It's not something you have any choice in; steel string guitars must use steel strings and classical guitar must use nylon strings.

- Q: How are steel coils inspected for surface finish after processing?

- Steel coils are inspected for surface finish after processing through visual inspection techniques such as using specialized lighting and magnification tools to detect any imperfections, scratches, or blemishes on the coil's surface.

- Q: LIke a steel building conversion into a residental building??? Thanks.

- Right here. Steel Homes, Steel House, Steel Buildings, Steel Home Plans, ... Steel Homes, Steel House, Steel Buildings, Steel Home Plans, Steel Houses, ... Steel Homes and Buildings · Steel Office Buildings and Construction sites ... www.karmod.eu/steel-structures - 18k - Similar pages www.karmod.eu/steel-structures steel buildings metal buildings modular homes steel building ... ... log homes photographs, log homes construction, sales agents, log homes financing, ... Easy online pricing

- Q: What are the common problems encountered with steel coils during production?

- Some common problems encountered with steel coils during production include surface defects such as scratches, rust, and scale formation, dimensional deviations, coil breaks or tears, edge defects, and coil slippage. Other issues may include coil handling and storage problems, coil winding or coiling defects, and quality control problems such as inconsistent chemical composition or mechanical properties.

- Q: I've been looking into battle-ready katanas a lot lately. And I've come across some debates between the best forges and steels to be used for them. The functional katanas I use now are Musashi brand katanas, using 1045 carbon steel. They each cost roughly $200-$250. The straight carbon steels are mentioned in the debates, but they aren't very sophisticated in their design. Now the higher end of this middle class of katana ($250-$1000) uses higher carbon. spring, damascus, and other various steels and combinations. I've heard a lot about the strength of damascus steel and it's cutting power. But I look for more than that. I've also been looking at (and for) durability, flexibility, and how well it stands up to contact. So I guess what I'm asking is for the opinion of people who have used these steels, and an answer on what the community thinks is the best steel for a mid range ($250-$1000) battle-ready katana. Looking forward to some good answers.

- This Site Might Help You. RE: Best battle-ready katana steel? I've been looking into battle-ready katanas a lot lately. And I've come across some debates between the best forges and steels to be used for them. The functional katanas I use now are Musashi brand katanas, using 1045 carbon steel. They each cost roughly $200-$250. The straight carbon...

Send your message to us

Electrical Cabinet Making Aluzinc 1.5mm Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords