Economy Grade Applications Masking Tape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 roll

- Supply Capability:

- 300000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General purpose of Economy Grade Applications Masking Tape

1) good adhesive

2) good flexibility

3) No residual left

4) Different sizes are available

Feature of Economy Grade Applications Masking Tape

general purpose masking tape, adhesive tape, paper tape.

1) good adhesion. 2) good flexibility.

-General purpose masking tape is made of crepe paper coated with natural rubber adhesives.

-It is designed for interior paint masking, light-duty packaging, holding, bundling, splicing and packaging.

-Practical for construction, building, home, office or industrial applications.

-Jumbo roll, log roll and cut roll are available.

-The width of jumbo roll is from 980mm - 1250mm

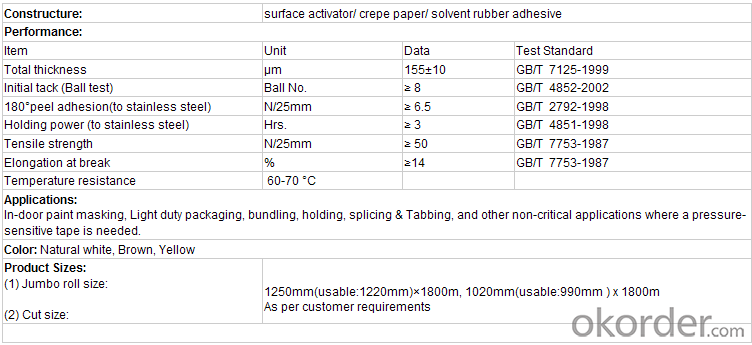

Specifications of Economy Grade Applications Masking Tape

Advantages of Economy Grade Applications Masking Tape

Different temperature resistance with good adhesion

High tensile strength, good resistance of damage, no residue, eco-friendly

Accept custom design

SGS, ISO, BV, CTI certificates approved

Professional teamwork for orders

No.267 on the 2014 Fortune Global 500

Professional manufacturer with 31 years experiences of adhesive tapes

Special size, color can be made according to customer's requirement.

Our Services

Your inquiry related to our product & price will be replied within 24 hours.

Well-trained & experienced staff can answer all your inquiries in English or other language

Your business relationship wit us will be confidential to any third party

Good after-sale service offered please free feel to contact us for more information

FAQ

Q 1: Do you have any MOQ of Wonder Masking Tape?

A: Yes, according to the size you need.

Q 2: What is the delivery time?

A: Sample time 7 days, 30 days for the mass production.

Q 3: Can we put our logo on the products?

A: Yes, welcome.

Q 4: How should I pay for you if I place order to you?

A: Usually, 30% T/T deposit in advance, 70% balance against the copy of B/L.

- Q: Can packaging tape be used for other purposes?

- Packaging tape has a wide range of uses beyond its intended purpose of sealing packages. Its strong adhesive properties and durability make it suitable for various applications. One popular alternative use for packaging tape is organizing and bundling items together. It can be used to sort and secure cables, cords, loose items, or similar objects, effectively keeping them organized. Additionally, it can be used to temporarily attach items like posters or decorations to walls or surfaces without causing any damage. Furthermore, packaging tape is great for crafting and DIY projects. Its adhesive nature allows it to create both temporary and permanent bonds between different materials. It can repair torn papers, create labels or tabs, or even make personalized stickers. Its versatility, available in different widths and lengths, makes it a valuable tool for creative endeavors. Moreover, packaging tape can be used for household fixes and repairs. Its strong adhesive properties can temporarily mend broken items or reinforce weak joints. It can also provide a temporary seal for minor leaks or cracks until a proper repair can be done. In conclusion, packaging tape's strong adhesive properties and versatility make it suitable for various purposes beyond sealing packages. Whether for organizing, crafting, or quick fixes, having packaging tape on hand can be highly useful.

- Q: Can packaging tape be used for outdoor applications?

- Yes, packaging tape can be used for outdoor applications. However, it is important to choose a tape specifically designed for outdoor use, as it needs to be weather-resistant and durable to withstand various environmental conditions such as rain, sunlight, and temperature fluctuations.

- Q: Is packaging tape transparent?

- Yes, packaging tape is usually transparent.

- Q: Are there different colors of packaging tape?

- In the market, one can find various colors of packaging tape. Although clear is the most commonly used color, there are also options like brown, white, black, and even vibrant choices such as red, blue, green, and yellow. The multiple colors of packaging tape serve different purposes. For instance, brown tape is frequently employed for sealing boxes and packages, white tape is commonly used for labeling or writing on, and colored tapes can be utilized for color-coding or enhancing the appearance of packages. The presence of diverse colors enables individuals and businesses to select the tape that best suits their specific requirements.

- Q: Can packaging tape be used for sealing plastic garment bags?

- Yes, packaging tape can be used for sealing plastic garment bags. Packaging tape is designed to provide a secure and durable seal on various materials, including plastic. It can help keep the plastic garment bag tightly sealed, preventing dust, moisture, and other contaminants from entering the bag and potentially damaging or dirtying the garments inside. Additionally, packaging tape is typically easy to use, as it can be easily cut with a dispenser or a pair of scissors, making it convenient for sealing plastic garment bags.

- Q: Is packaging tape resistant to oil or grease?

- Yes, packaging tape is generally resistant to oil or grease. Packaging tapes are designed to securely seal boxes and packages, ensuring that the contents inside are protected during transportation. These tapes are typically made of materials such as polypropylene or PVC, which have properties that make them resistant to various substances including oil and grease. This resistance helps to prevent the tape from deteriorating or losing its adhesion when it comes into contact with oils or greases commonly found in industrial or commercial settings. However, it is important to note that the level of resistance may vary depending on the specific type and quality of packaging tape used.

- Q: Does packaging tape come in different finishes or textures for aesthetic purposes?

- Yes, packaging tape does come in different finishes or textures for aesthetic purposes. Some examples include glossy, matte, clear, colored, patterned, and even customizable options. These variations allow individuals and businesses to choose packaging tape that aligns with their branding or personal preferences.

- Q: Can packaging tape be used for sealing cardboard boxes?

- Yes, packaging tape is commonly used for sealing cardboard boxes as it provides a strong and secure bond.

- Q: Can packaging tape be used for sealing gardening or outdoor equipment?

- Yes, packaging tape can be used for sealing gardening or outdoor equipment. It provides a strong adhesive bond and can effectively seal boxes or other packaging materials used for storing or transporting gardening or outdoor equipment. However, it is important to consider the durability and weather resistance of the tape to ensure it withstands outdoor conditions.

- Q: What are the common color options for packaging tape?

- The common color options for packaging tape vary depending on the manufacturer and the intended use. However, some of the most commonly available colors for packaging tape include clear, brown, white, and tan. Clear packaging tape is transparent and allows the content of the package to be visible. Brown packaging tape, often referred to as brown or tan tape, is a popular choice for sealing boxes and packages as it provides a strong and secure hold. White packaging tape is another option that is often used for labeling purposes, as it allows for easy writing or printing of information on the tape. Additionally, there are various other colors available for packaging tape, such as red, blue, green, and yellow, which can be useful for color-coding or for adding visual appeal to packages. Ultimately, the choice of color for packaging tape depends on personal preference, branding requirements, or specific organizational needs.

Send your message to us

Economy Grade Applications Masking Tape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 roll

- Supply Capability:

- 300000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords