Eco-friendly 100pp nonwoven polyester spunbond non woven fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

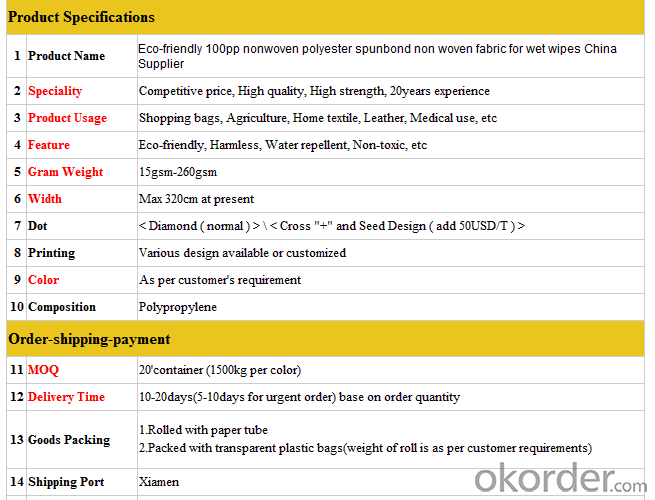

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: Application of Biological Enzyme in Textile Processing

- The application of new enzymes in textile processing: the position of chemical synthetic fibers and slurries in the textile is obvious, these polymer can not be biodegradable and degraded, causing environmental pollution, the current researchers are studying the new enzyme

- Q: The weight of the textile fabric

- Fabric cost = raw material cost + weaving costs + dyeing after finishing processing fees + test volume packaging costs + tax + loss of all links

- Q: How can paint points be removed during textile processing?

- So, if it is a slight, a small amount of paint points, you can use butyl acetate rubbed, and then through the conventional pre-treatment process to remove it

- Q: What is the difference between the nonwovens industry and the textile industry?

- Nonwovens finished low, to replace the traditional textiles, of course, is able to replace the place

- Q: Textile industry belongs to the first few industries

- The first industry in the "classification of national economic industry" (GB / T 4754-2002), a category that is Class A, including agriculture, forestry, animal husbandry, fisheries and agriculture, forestry, animal husbandry, fishing services a total of five categories; Mining and salt industry into the secondary industry.

- Q: What is the purpose of using detergent in the textile industry?

- For the woven fabric, the desizing process can also add some detergent to improve the effect.

- Q: The difference between double distribution and processing in textile fabrics

- Distribution - that is, you buy fabrics, only the money on the line, all of them will give you a good job.

- Q: tera textile processing where to learn

- TERA in the textile is to collect the fiber obtained by processing can be made of clothing materials technology, with the increase in proficiency can produce high-quality silk.

- Q: Analysis of import and export of textile

- In recent years, China's textile industry, the overall size of the overall growth rate showed a gradual slowdown trend. In 2013, China's fiber processing volume reached 48.5 million tons, compared with 2010 increased by 17.4%, an average annual growth of 5.5%, while the first decade of the century, that is, 2001 to 2010, the average annual growth rate of 11.7%

- Q: What is the earliest textile raw material?

- The ancient Roman Empire was first through the "Silk Road" on the spread of silk, said China as "silk country"

Send your message to us

Eco-friendly 100pp nonwoven polyester spunbond non woven fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords