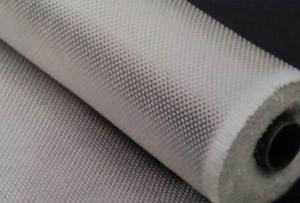

E Glass Woven Roving Fiberglass Mat Tissue

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction

E-Glass Woven Rovings are compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

E-Glass Woven Rovings are a high-performance reinforcement widely used in hand lay up and robot processes to manufacture boats, vessels, plane and automotive parts, furniture and sports facilities.

Characteristics

Warp and weft rovings aligned in a parallel and flat manner, resulting in uniform tension

Densely aligned fibers, resulting in high dimensional stability and making handling easy

Product Specifications

Property | Area Weight | Moisture Content | Size Content | Width |

(%) | (%) | (%) | (mm) | |

Test Method | IS03374 | ISO3344 | ISO1887 | |

EWR200 | ±7.5 | ≤0.15 | 0.4-0.8 | 20-3000 |

EWR270 | ||||

EWR300 | ||||

EWR360 | ||||

EWR400 | ||||

EWR500 | ||||

EWR600 | ||||

EWR800 |

Special specification can be produce according to customer requirements.

FAQ

Packaging:Each woven roving is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 220mm. The woven roving roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:Unless otherwise specified,It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: What is the dimensional stability of fiberglass mat tissue?

- The dimensional stability of fiberglass mat tissue refers to its ability to maintain its size and shape under various conditions. Fiberglass mat tissue is known for its excellent dimensional stability, making it highly resistant to shrinking, expanding, or warping. This stability is achieved through the manufacturing process, which involves bonding glass fibers together using a binder material. This binder not only ensures the integrity of the mat tissue but also helps it maintain its dimensional stability over time. Additionally, the inherent properties of fiberglass, such as its high strength and stiffness, contribute to its exceptional dimensional stability. These characteristics make fiberglass mat tissue a popular choice in various applications, including construction, automotive, and aerospace industries, where consistent dimensions are crucial for optimal performance and durability.

- Q: Can fiberglass mat tissue be used for HVAC insulation?

- No, fiberglass mat tissue is not typically used for HVAC insulation. HVAC insulation usually requires materials that are specifically designed to have high thermal resistance and to prevent the transfer of heat or cold air. Fiberglass mat tissue is commonly used as a reinforcement material in the fabrication of composite materials, such as fiberglass panels or structures, rather than as insulation. Insulation materials for HVAC systems are typically made from materials like fiberglass insulation boards, foam insulation, or mineral wool, which have better thermal resistance properties and are specifically designed for HVAC applications.

- Q: What are the different weights available for fiberglass mat tissue?

- Various industries, including construction, automotive, and marine, utilize fiberglass mat tissue extensively. This versatile material is available in different weights or thicknesses to meet various applications and specifications. The weight of fiberglass mat tissue is typically measured in grams per square meter (gsm) or ounces per square yard (oz/yd²). Typically, the available weights for fiberglass mat tissue range from approximately 30 gsm (1 oz/yd²) to 150 gsm (5 oz/yd²) or higher. The weight of the tissue directly affects its strength, rigidity, and durability. For applications that require a high degree of flexibility and conformability, lightweight fiberglass mat tissue weighing around 30-50 gsm (1-1.5 oz/yd²) is commonly used. These lighter weight tissues are often employed in the production of laminates, reinforcing materials, and lightweight composites. Medium weight fiberglass mat tissue, typically falling within the range of 70 gsm (2 oz/yd²) to 100 gsm (3 oz/yd²), strikes a balance between flexibility and strength. It finds frequent use in applications such as roofing, insulation, and wall panels, where structural integrity and thermal insulation properties are of utmost importance. For applications that demand exceptional strength and rigidity, heavyweight fiberglass mat tissue weighing between 120 gsm (4 oz/yd²) and 150 gsm (5 oz/yd²) or more is ideal. This type of tissue is commonly employed in demanding applications like boat hulls, automotive body parts, and industrial equipment, where durability and resistance to impact and stress are critical. It is important to recognize that the availability of different weights of fiberglass mat tissue may vary depending on the manufacturer and the specific requirements of the application. In certain cases, custom weights can be manufactured to meet unique project needs. In summary, fiberglass mat tissue is available in a range of weights to accommodate diverse applications. Selecting the appropriate weight is essential to ensuring optimal performance and long-term durability in various industries.

- Q: How is fiberglass mat tissue used in the production of shower enclosures?

- The production of shower enclosures commonly utilizes fiberglass mat tissue due to its exceptional properties and advantages. This thin and flexible material consists of fine glass fibers that are randomly distributed and bonded together with a resin binder. To strengthen and enhance the shower enclosure, fiberglass mat tissue is primarily used as a reinforcement material. It is applied to the enclosure's surface to improve its strength, durability, and resistance to cracking or breaking. Initially, the fiberglass mat tissue is cut and sized according to the specific dimensions of the shower enclosure. It is then carefully placed or applied onto the enclosure's surface, typically through a process known as hand lay-up or spray-up. The mat tissue is strategically positioned to cover critical areas requiring reinforcement, such as corners, edges, and joints. Once the mat tissue is in position, a resin, usually polyester or epoxy, is applied over it. The resin penetrates the fiberglass mat tissue and bonds with the fibers, creating a solid and sturdy composite structure. This combination of resin and fiberglass provides additional strength and stability to the shower enclosure, making it more resistant to impact, stress, and water or humidity. Additionally, fiberglass mat tissue also contributes to the overall appearance of the shower enclosure. It helps achieve a smooth and uniform surface finish, eliminating imperfections and creating an aesthetically pleasing look. The mat tissue can be easily molded or shaped to match different designs and styles, enabling manufacturers to produce shower enclosures of various shapes, sizes, and patterns. In conclusion, fiberglass mat tissue plays a crucial role in the production of shower enclosures by offering reinforcement, strength, durability, and aesthetic benefits. This versatile material enhances the overall performance and visual appeal of the enclosures, ensuring they can withstand daily use and maintain their quality over time.

- Q: What are the typical mechanical properties of fiberglass mat tissue?

- The typical mechanical properties of fiberglass mat tissue include high strength, excellent tensile and tear resistance, good dimensional stability, and low elongation. Additionally, it has a high modulus of elasticity and is resistant to corrosion, chemicals, and moisture.

- Q: Can fiberglass mat tissue be used for reinforcing wind turbine blades?

- Yes, fiberglass mat tissue can be used for reinforcing wind turbine blades. Fiberglass mat tissue is a lightweight and flexible material made from thin glass fibers bonded together with a resin. It is commonly used in various applications where strength and durability are required, including the construction of wind turbine blades. Wind turbine blades need to be strong yet lightweight to efficiently harness the power of the wind. They are exposed to various forces such as wind loads, vibrations, and extreme weather conditions. Fiberglass mat tissue is an ideal choice for reinforcing these blades due to its excellent mechanical properties. It provides high tensile strength and stiffness, which helps the blades withstand the stress and strain they experience during operation. Additionally, fiberglass mat tissue has good resistance to corrosion and fatigue, which are important factors for the long-term performance of wind turbine blades. It also offers good dimensional stability, ensuring that the shape and integrity of the blades are maintained over time. Furthermore, fiberglass mat tissue can be easily molded and shaped, allowing for complex and aerodynamic blade designs. It can be layered and combined with other materials, such as epoxy resin, to create a composite structure that maximizes the strength and performance of the wind turbine blades. In conclusion, fiberglass mat tissue is a suitable and commonly used material for reinforcing wind turbine blades. Its lightweight, high strength, corrosion resistance, and moldability make it an excellent choice for ensuring the structural integrity and efficiency of wind turbines.

- Q: How does fiberglass mat tissue enhance the strength of composite materials?

- The enhancement of composite material strength is greatly influenced by fiberglass mat tissue. Made up of thin fiberglass strands woven together, the tissue possesses a distinctive structure, with the strands randomly oriented and bonded by a resin binder. This unique structure offers several advantages to composite materials. Firstly, the random orientation of the fiberglass strands within the tissue aids in the even distribution of stress and load across the composite material. Consequently, when a force is exerted on the composite, the tissue prevents localized stress concentrations that could result in cracks or failure. By distributing stress, the fiberglass mat tissue enhances the overall strength and durability of the composite material. Secondly, the resin binder utilized in the fiberglass mat tissue serves as both a reinforcement and bonding agent. During the manufacturing process of the composite material, the resin binder infiltrates the fibers of the tissue, creating a robust and cohesive structure. This not only enhances the overall strength of the composite material but also improves its resistance to impact and fatigue. Moreover, the presence of fiberglass strands within the tissue augments the stiffness of the composite material. When combined with the resin binder, these strands establish a rigid framework that enhances the structural integrity of the composite. This increased stiffness renders the material more resistant to deformation and improves its load-bearing capabilities. Additionally, fiberglass mat tissue offers thermal and electrical insulation properties to composite materials. The fiberglass strands act as a barrier, minimizing heat transfer and preventing electrical conductivity. Consequently, the composite material becomes suitable for applications that require insulation, such as in electrical enclosures or thermal insulation panels. In conclusion, fiberglass mat tissue plays a critical role in enhancing the strength of composite materials by distributing stress, reinforcing the structure, increasing stiffness, and providing additional insulation properties. With its random orientation, resin binder, and unique characteristics, it is an indispensable component in the production of high-performance composites utilized across various industries, including aerospace, automotive, construction, and marine.

- Q: Can fiberglass mat tissue be used for insulation in research laboratories?

- Indeed, insulation in research laboratories can utilize fiberglass mat tissue. This material, widely employed for thermal and acoustic insulation, boasts exceptional insulating qualities. Its resistance to heat, moisture, and chemicals renders it ideal for laboratory environments. Moreover, fiberglass mat tissue's lightweight nature and effortless installation enable swift and efficient insulation in research laboratories. Its low thermal conductivity further aids in maintaining stable temperature conditions, guaranteeing optimal experiment conditions while curbing energy consumption. In conclusion, fiberglass mat tissue presents itself as a practical option for insulating research laboratories.

- Q: What is the weight of fiberglass mat tissue per square meter?

- The weight per square meter of fiberglass mat tissue may differ based on the particular product and manufacturer. Typically, the weight of fiberglass mat tissues can range from 100 grams per square meter (gsm) to 900 gsm. Nevertheless, it should be noted that in certain instances, the weight may also be expressed in ounces per square yard (oz/yd²). To ascertain the precise weight of a particular fiberglass mat tissue, it is advisable to consult the manufacturer's provided product specifications.

- Q: Is fiberglass mat tissue suitable for automotive applications?

- Yes, fiberglass mat tissue is suitable for automotive applications. Fiberglass mat tissue is a versatile material that offers numerous benefits when used in automotive applications. It provides excellent strength and durability, which is essential for automotive parts that need to withstand harsh conditions and heavy usage. Fiberglass mat tissue also has good thermal and electrical insulation properties, making it suitable for applications where temperature resistance and electrical insulation are required. Additionally, fiberglass mat tissue is lightweight, which can help improve fuel efficiency and overall vehicle performance. It is also easy to mold and shape, allowing manufacturers to create complex automotive parts with precision. Furthermore, fiberglass mat tissue is resistant to corrosion, chemicals, and UV radiation, ensuring the longevity and reliability of automotive components. Overall, the unique properties of fiberglass mat tissue make it an ideal choice for various automotive applications, including but not limited to body panels, interior components, structural reinforcements, and sound insulation. Its strength, durability, insulation properties, lightweight nature, and resistance to corrosion and chemicals make it a reliable and cost-effective material for the automotive industry.

Send your message to us

E Glass Woven Roving Fiberglass Mat Tissue

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords