Fiberglass Mat Tissue E Glass Fiber Woven Roving for Boat Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

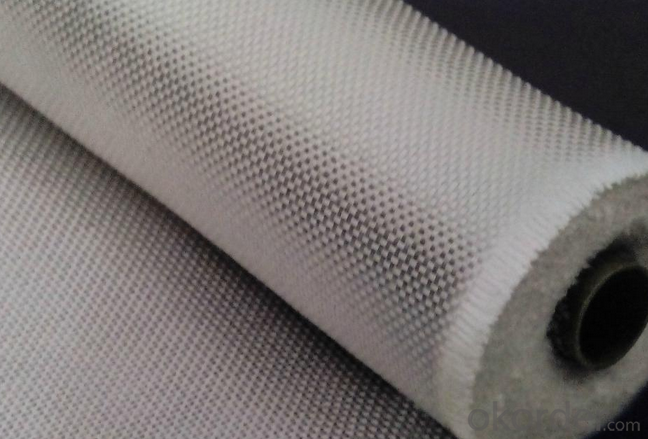

Structure of woven roving Description

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

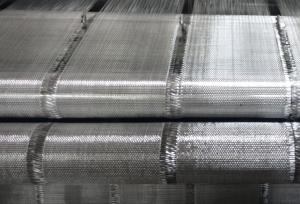

Main Features of the woven roving

1) Woven roving is a kind of evenly distributed material which owns high strength on both side with high intensity, the fiber content and strength is even higher during the production of FRP products.

2) Benefit from the production procedure and the material itself, the fabric maintains high percentage of its material strength, and also very easy for the resin to penetrate.

Woven roving Images

Woven roving Specification:

Normal type | EWR800 | EWR400 | EWR300 | EWR500 | EWR600 |

Thickness (mm) | 0.8 | 0.4 | 0.3 | 0.5 | 0.6 |

Density(warpxweft) (end/cm) | 1.8x1.5+/-10% | 3.6x3.2+/-10% | 4.6x4.1+/-10% | 2.2X2.0+/-10% | 2.6X2.4+/-10% |

Tex (warpxweft) | 2400x2400 | 600X600 | 300x400 | 1200x1200 | 1200X1200 |

Moisture content(%) | <0.2% | <0.2% | <0.2% | <0.2% | <0.2% |

Loss on ignition(%) | 0.4 – 0.8 | 0.4-0.8 | 0.4-0.8 | 0.4-08 | 0.4-0.8 |

Width(cm) | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 |

Weight (g/m2) | 816+/-41 | 408+/-32 | 300+/-15 | 500+/-25 | 600+/-30 |

Weight per roll(kg) | 45 | 46 | 50 | 45 | 45 |

Glass | E-glass | E-glass | E-glass | E-glass | E-glass |

FAQ of woven roving:

1. Your inquiry will be replied within 24hours

2. Well-trained and experienced staffs will answer all your inquiries at first time..

3. All our products have warranties.

4. Offering the support to solve the problem during the application or selling period.

5. Good quality with competitive price.

6. The same quality of samples and mass products is granted.

- Q: Is fiberglass mat tissue fire-resistant?

- Yes, fiberglass mat tissue is fire-resistant.

- Q: Is fiberglass mat tissue suitable for marine repairs?

- Yes, fiberglass mat tissue is suitable for marine repairs. It is commonly used in boat and yacht repairs due to its excellent strength, durability, and resistance to water and corrosion. Additionally, fiberglass mat tissue is easy to work with and can be used for various applications such as hull, deck, and structural repairs in marine environments.

- Q: How does the density of fiberglass mat tissue affect its performance?

- The density of fiberglass mat tissue significantly affects its performance. Fiberglass mat tissue is typically used in various applications, such as insulation, construction materials, and composite materials. The density of the fiberglass mat tissue determines its strength, durability, flexibility, and thermal insulation properties. A higher density fiberglass mat tissue generally offers better strength and durability. This is because a higher density implies more fiberglass strands are packed closely together, resulting in a denser and stronger material. It can withstand higher loads and impacts, making it suitable for applications requiring structural integrity, such as in construction or automotive industries. Moreover, the density of fiberglass mat tissue also influences its flexibility. A lower density fiberglass mat tissue tends to be more pliable and easier to shape. It can be molded into intricate shapes and contours, making it suitable for applications where flexibility is essential, such as in boat manufacturing or automotive body parts. The density also affects the thermal insulation properties of fiberglass mat tissue. Higher density fiberglass mat tissue offers better insulation against heat transfer. It effectively prevents the transfer of heat through conduction, making it ideal for insulation purposes, such as in buildings or piping systems. However, it is important to note that the density of fiberglass mat tissue should be chosen based on the specific requirements of the application. While higher density may provide better strength and durability, it also increases the weight and cost of the material. Therefore, a balance needs to be struck between the desired performance characteristics and the practicality of the specific application.

- Q: Can fiberglass mat tissue be used for insulating concrete forms (ICFs)?

- Yes, fiberglass mat tissue can be used for insulating concrete forms (ICFs). It is commonly used as a reinforcement material in ICF construction due to its excellent insulation properties and ability to improve the overall strength and durability of the concrete structure.

- Q: Can fiberglass mat tissue be used for aerospace applications?

- Yes, fiberglass mat tissue can be used for aerospace applications. It is commonly used as a reinforcing material in the aerospace industry due to its excellent mechanical properties, such as high strength-to-weight ratio and resistance to corrosion. Additionally, fiberglass mat tissue can provide thermal insulation and fire resistance, making it suitable for various aerospace components, including aircraft interiors, panels, and structural parts.

- Q: Can fiberglass mat tissue be used for architectural applications?

- Certainly! Fiberglass mat tissue is applicable for architectural purposes. This versatile material offers numerous advantages when utilized in architectural undertakings. It functions predominantly as a reinforcement material for the construction of architectural components such as roofs, facades, and walls. The principal benefit of fiberglass mat tissue for architectural use lies in its exceptional strength-to-weight ratio. It provides outstanding structural integrity while remaining lightweight, rendering it highly suitable for extensive architectural ventures. Moreover, fiberglass mat tissue exhibits durability and resistance against severe weather conditions, enabling its application both indoors and outdoors. Furthermore, fiberglass mat tissue possesses commendable fire resistance attributes, a vital aspect in adhering to architectural safety standards. With a high melting point and the absence of flame propagation, it proves to be a dependable choice for fire-resistant applications. In terms of aesthetics, fiberglass mat tissue can be effortlessly molded into various shapes and designs, granting architects the freedom to explore creative possibilities. It can be painted or coated to achieve the desired visual appearance, thus establishing its versatility as an architectural finishing material. In conclusion, fiberglass mat tissue emerges as a trustworthy and adaptable material suitable for diverse architectural projects. Its strength, durability, fire resistance, and aesthetic flexibility make it an ideal choice for a wide spectrum of architectural applications.

- Q: What is the tensile strength of fiberglass mat tissue?

- Fiberglass mat tissue usually has a tensile strength ranging from 30 to 150 pounds per inch (lb/in). Nevertheless, it is crucial to bear in mind that the precise tensile strength may differ based on the particular type and quality of fiberglass mat tissue utilized.

- Q: How does fiberglass mat tissue compare to mineral wool insulation?

- Fiberglass mat tissue and mineral wool insulation are two common types of insulation materials used in construction and other industries. While both materials serve the purpose of providing thermal insulation, there are some differences between the two. Fiberglass mat tissue is made from fine glass fibers that are bonded together to form a mat. It is lightweight and flexible, making it easy to handle and install. Fiberglass mat tissue is also resistant to moisture, mold, and pests, making it a durable option for insulation. It has a high R-value, which measures the material's ability to resist heat flow, making it an effective insulator. On the other hand, mineral wool insulation is made from natural minerals such as basalt, diabase, or slag. It is typically denser and heavier than fiberglass mat tissue. Mineral wool insulation is known for its excellent fire resistance properties, as it is non-combustible and can withstand high temperatures. It also provides sound insulation, reducing noise transmission. However, mineral wool insulation can absorb moisture, which can reduce its effectiveness over time. In terms of thermal performance, both materials offer similar levels of insulation. However, fiberglass mat tissue tends to be slightly more efficient due to its higher R-value. Additionally, fiberglass mat tissue is generally more affordable compared to mineral wool insulation. In conclusion, fiberglass mat tissue and mineral wool insulation are both effective insulation materials. The choice between the two will depend on specific project requirements, such as fire resistance, sound insulation, cost, and moisture resistance. It is important to consider these factors and consult with professionals to determine the most suitable insulation material for a particular application.

- Q: Can fiberglass mat tissue be used for reinforcing wind turbine blades?

- Yes, fiberglass mat tissue can be used for reinforcing wind turbine blades. It is commonly utilized in the manufacturing process as it provides strength, durability, and flexibility to the blades, making them more capable of withstanding the forces and stresses experienced during operation.

- Q: Can fiberglass mat tissue be used for making boat hulls?

- Yes, fiberglass mat tissue can be used for making boat hulls. Fiberglass mat tissue is a lightweight and strong material that is commonly used in boat building and repair. It is made by bonding strands of fiberglass together with a binder, resulting in a flexible mat that can be easily formed and molded into various shapes. Boat hulls require a material that is durable, water-resistant, and has good structural integrity, all of which fiberglass mat tissue provides. Additionally, fiberglass mat tissue is relatively easy to work with and can be layered to increase its strength as needed. Therefore, it is a popular choice for constructing boat hulls.

Send your message to us

Fiberglass Mat Tissue E Glass Fiber Woven Roving for Boat Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords