Fiberglass Mat Tissue - E-Glass Fiberglass Type Jushi Fiberglass Chopped Strand Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

E-Glass Fiberglass Type Jushi Fiberglass Chopped Strand Mat

Introduction:

Chopped Strand Mat is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the application by hand lay-up FRP moldings, such as, various sheets and panels, boat hulls, boat tubs, cooling towers, corrosion resistant, vehicles, etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

Consistent thickness and stiffness;

Rapid impregnating and good compatibility with resin;

Superior wet through with less air trap;

Good mechanical properties and high strength of parts.

Superior acid corrosion resistance

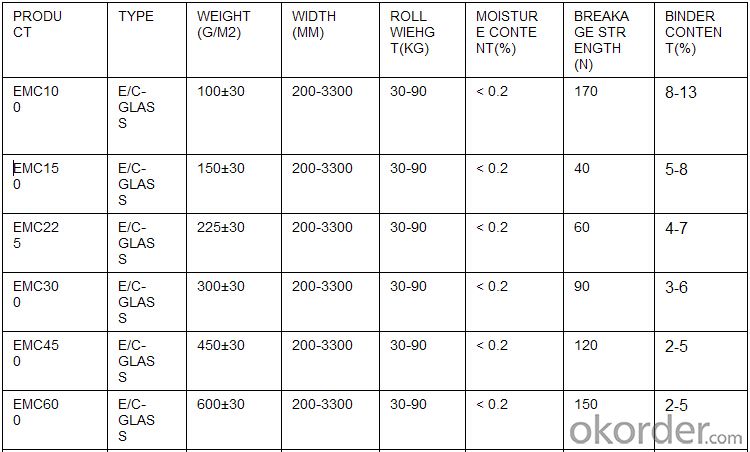

Technical Data:

Packaging:

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Is fiberglass mat tissue suitable for wind energy applications?

- Indeed, fiberglass mat tissue proves to be a fitting choice for wind energy applications. This lightweight and resilient material is often employed in the fabrication of wind turbine blades. It possesses remarkable strength and rigidity, rendering it well-suited to endure the formidable strains and pressures exerted on wind turbines. Furthermore, fiberglass mat tissue exhibits resistance against corrosion and deterioration caused by UV radiation, thereby guaranteeing the durability and functionality of wind turbine blades. In summary, the integration of fiberglass mat tissue into wind energy applications enables the creation of efficient and dependable wind turbines capable of generating clean and sustainable energy.

- Q: How does the roll length of fiberglass mat tissue affect its handling?

- The roll length of fiberglass mat tissue can have an impact on its handling in several ways. Firstly, a longer roll length means that the roll will be heavier and larger in size. This can make it more challenging to handle and maneuver, especially if the roll needs to be transported or lifted to different areas. It may require additional manpower or equipment to safely handle and move the roll. Secondly, the length of the roll can also affect how easily the fiberglass mat tissue can be unrolled and cut to size. Longer rolls may be more prone to tangling or becoming tangled, which can make it more difficult to unroll the tissue smoothly and evenly. This can result in wasted material or uneven application. Additionally, the length of the roll can also impact the storage and space requirements. Longer rolls may take up more space and require larger storage areas. This can be a consideration for manufacturers or distributors who need to store large quantities of fiberglass mat tissue. In summary, the roll length of fiberglass mat tissue can affect its handling by making it heavier and more difficult to maneuver, potentially leading to tangling or uneven unrolling, and requiring larger storage space.

- Q: Does fiberglass mat tissue provide good acoustical performance?

- Fiberglass mat tissue does provide good acoustical performance. Due to its composition, which includes fine glass fibers, this material is effective in absorbing sound waves and reducing echo and reverberation in a space. Fiberglass mat tissue has excellent sound absorption properties, making it suitable for applications in various industries such as construction, automotive, and aerospace. Its ability to dampen sound and improve acoustics makes it a popular choice for soundproofing walls, ceilings, and floors in buildings. Additionally, fiberglass mat tissue is lightweight and easy to install, further enhancing its appeal for acoustical applications.

- Q: What is the expected lifespan of fiberglass mat tissue?

- The expected lifespan of fiberglass mat tissue can vary depending on several factors such as the quality of the material, the conditions it is exposed to, and the specific application it is used for. However, on average, fiberglass mat tissue is known for its durability and long lifespan. When properly manufactured and installed, fiberglass mat tissue can last for several decades. It is resistant to rot, corrosion, and many chemicals, making it suitable for various industries and applications. Additionally, fiberglass mat tissue is known for its strength and ability to withstand high temperatures. However, it is important to note that exposure to harsh environmental conditions, such as extreme temperatures, UV radiation, and moisture, can potentially degrade the material over time. Regular maintenance and proper care can help extend the lifespan of fiberglass mat tissue. Overall, while it is challenging to determine an exact expected lifespan for fiberglass mat tissue, it is generally considered to be a long-lasting material when used and maintained correctly.

- Q: How does the roll weight of fiberglass mat tissue affect its transportation?

- The roll weight of fiberglass mat tissue can have a significant impact on its transportation process. The weight of the roll determines the ease of handling and the logistics required for transportation. Firstly, a heavier roll weight can make it more challenging to move and handle the fiberglass mat tissue. If the roll is too heavy, it may require specialized equipment or machinery for loading and unloading, such as forklifts or cranes. This can add complexity and cost to the transportation process. Moreover, the weight of the roll also affects the packaging and storage requirements during transportation. Heavier rolls may require sturdier packaging materials and additional precautions to ensure their stability and prevent any damage during transit. This can include using pallets, strapping, or other securing methods to prevent the roll from shifting or falling during transportation. The weight of the roll also impacts the overall cost of transportation. Heavier rolls can increase shipping costs, as carriers often charge based on weight. Additionally, the weight of the roll can affect the number of rolls that can be transported in a single shipment, which can impact the efficiency and cost-effectiveness of the transportation process. In summary, the roll weight of fiberglass mat tissue plays a crucial role in its transportation. It affects the ease of handling, packaging requirements, and overall cost of transportation. Therefore, it is essential to consider the roll weight when planning and organizing the logistics for transporting fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for bridge construction?

- Yes, fiberglass mat tissue can be used for bridge construction. It is often used as a reinforcement material in the construction of bridges due to its high strength, durability, and resistance to corrosion. It helps to improve the overall structural integrity and longevity of the bridge.

- Q: Does anyone know the hardness value of the heat conductive gasket? Does it contain the hardness of the carrier (glass fiber)?

- SHORE hardness is only for the hardness of the heat conductive gasket itself

- Q: How does fiberglass mat tissue compare to other types of reinforcement materials?

- Fiberglass mat tissue is a versatile reinforcement material that offers several advantages over other types of reinforcement materials. Firstly, it has excellent strength and stiffness properties, providing superior load-bearing capabilities compared to other materials. Secondly, fiberglass mat tissue is lightweight, making it easier to handle and install. Additionally, it is highly resistant to corrosion, chemicals, and moisture, ensuring long-term durability. Lastly, fiberglass mat tissue has excellent dimensional stability and is not prone to warping or shrinking, making it a reliable choice for various applications. Overall, its combination of strength, lightweight nature, durability, and dimensional stability sets fiberglass mat tissue apart from other reinforcement materials.

- Q: Can fiberglass mat tissue be used for repairing fiberglass tanks?

- Yes, fiberglass mat tissue can be used for repairing fiberglass tanks. Fiberglass mat tissue is a thin, flexible material that is commonly used in the construction and repair of fiberglass products. It is designed to provide reinforcement and strength to the repaired areas. When applied with an appropriate resin, fiberglass mat tissue can effectively repair cracks, holes, or damaged sections of fiberglass tanks. However, it is important to ensure that the repair is done in a proper and professional manner, following the manufacturer's instructions and guidelines. Additionally, it is recommended to consult with an expert or specialist in fiberglass repair to ensure the best possible outcome for the repair.

- Q: How does the thickness of fiberglass mat tissue affect its performance?

- The thickness of fiberglass mat tissue directly affects its performance. A thicker tissue provides increased strength, durability, and insulation properties. It also enhances the material's ability to absorb impact and resist damage. Thinner tissues, on the other hand, offer greater flexibility and easier handling. Therefore, choosing the appropriate thickness of fiberglass mat tissue is crucial to achieve desired performance characteristics in various applications.

Send your message to us

Fiberglass Mat Tissue - E-Glass Fiberglass Type Jushi Fiberglass Chopped Strand Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords