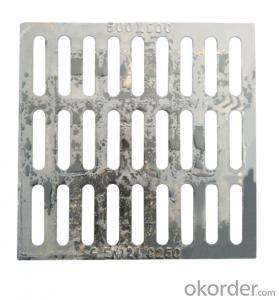

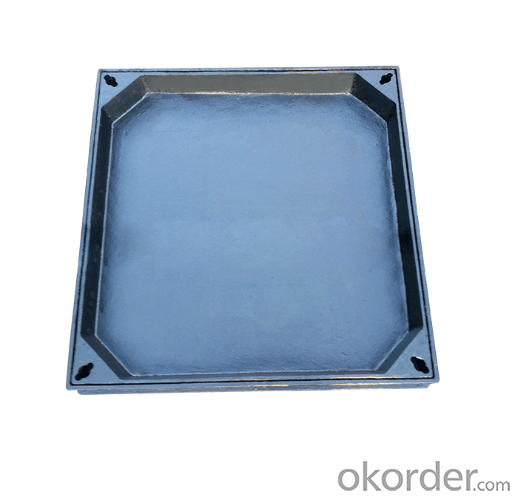

Ductile Cast Iron Square Double Seal Manhole Cover & Frame

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 set

- Supply Capability:

- 4100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron,

3) Type:round type and Square type,triangle

4) Sand casting

5)We can produce as per customers' drawings.

6)ISO9001:2008

Specification

| No. | Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Unit Weight (kg/set) |

| 1 | CHB40 | B125 | 310×310 | 400×400 | 18 |

| 2 | CHB50 | B125 | 400×400 | 500×500 | 17 |

| 3 | CHB60 | B125 | 500×500 | 600×600 | 26 |

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years). The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than. Contain no metal and no recovery value, anti-theft.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet

Delivery Detail: 8 days if your order is 20"container

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our products: produced by the hydraulic Press. Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

FAQ

1.Q: Are you factory ?

YES! We are a professional ductile iron & grey iron casting Factory inChina.

2.Q: How long can you make your quotation:

Within 3 workdays after received your detailed product information

3.Q: Do you provide OEM Service?

Yes, we provide OEM Service.

4.Q: What 's your quotation element?

Drawing, material, weight and quantity.

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- The aim is to make the grain fine and distribute the carbide evenly. The difference between normalizing and annealing is that normalizing cooling rate is slightly faster than annealing cooling rate, so normalizing structure is finer than annealing structure, and its mechanical properties are also improved. In addition, normalizing furnace cooling does not occupy equipment and has higher productivity. Therefore, normalizing may be used instead of annealing as much as possible. The main application areas of normalizing are as follows: for low carbon steel, after normalizing, the hardness is slightly higher than that of annealing, and the toughness is better. It can be used as the pretreatment of cutting. Used for medium carbon steel, instead of quenching and tempering, as the final heat treatment, or as an induction heating method before surface hardening. Used for tool steel, bearing steel, carburizing steel, etc., it can eliminate or restrain the formation of network carbide, so as to obtain the good organization of spheroidizing annealing. For cast steel, the microstructure can be refined and the machinability can be improved. Used for large forgings, which can be used as final heat treatment, so as to avoid larger cracking tendency during quenching.

- Q: What's the effect of casting copper?

- In general cast iron, the mass fraction of copper below 3% - 3.5% can increase the hardness; but when the cast iron has a tendency to chill, or when there is a hard point of free carbides, the addition of copper decreases the hardness.Copper can be used to improve the wear resistance, abrasion resistance, and shock absorption of cast iron, so it is often used in the manufacture of sliding friction iron castings, such as drilling machine spindle, automobile and tractor, valve tappet, etc.. But in white cast iron or chilled cast iron, adding copper does not make any improvement in its abrasion resistance.Copper for certain heat resistant cast iron and austenitic cast iron can increase the heat resistance and corrosion resistance, copper - chromium composite alloy to prevent oxidation under high temperature in the atmosphere from the skin effect is particularly effective, heat resistance and corrosion resistance of austenitic cast iron containing many mass fraction of 4% ~ 7% copper.

- Q: What are the requirements for casting steel castings?

- 4 thickness, most should be placed above the.5 and try to reduce the number of.6, the sand core should be used in classification of flat surface

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angle

- Q: For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- For example, the castings shall be in accordance with the requirements of the second types of castings in the technical requirements for aluminum alloy castings of GB/T9438-1999;

- Q: What are the causes of pitting on the surface of a precision casting?

- The quality of the shell surface is out of order. Or shot blasting out of question.

- Q: How to distinguish the forging parts and casting parts accurately

- Distinguish from performance:The processing performance of forged parts is higher than that of the same material. The forging parts are compact and have good mechanical properties, but the casting parts may have sand holes, holes, shrinkage holes and other defects, and their mechanical properties are inferior to those of forgings. At the same time, forging processing can ensure the continuity of the metal fibrous tissue, fibrous tissue to forging and forging shape consistency, metal streamline integrity, can ensure the parts with mechanical properties and long service life good.

- Q: What kind of flaw detector is better for casting parts?

- If you want to detect internal defects, you can use ultrasonic flaw detector, ray flaw detector can also, but the ray of the safety protection level is too high, not recommended priorityMacro Xu flaw detector answered, such as the magnetic particle inspection machine has the demand can contact us, Baidu "macro Xu flaw detection""

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Proofing? In the casting industry is not called proofing, proofing is generally used in the printing industry, that is, according to the customer's drawings or samples, to do a first piece, to provide customers with the inspection process to meet their requirements;In the foundry industry, providing prototypes is sometimes difficult:1, customers if the provision of mold, it would be best, at this time, sample costs are very low, and almost the same as your regular products;2, the customer does not provide the mold, but in business relationships, your factory and not very sure must take this one, it requires your leadership decision-making, is free or low cost, or by a strict process offer (of course sample);3, not all of the casting process to provide samples are difficult, like lost foam can directly make a white NC prototype, and then assembled pouring, this is her unique advantages, first cost less than the opening process and so on;If you don't understand, you can continue to question me

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- If is casting, internal shell mold may be not completely dry, strength is not enough, resulting in shell mold collapse into molten steel.It is also possible that the refractory is not refractory enough.

Send your message to us

Ductile Cast Iron Square Double Seal Manhole Cover & Frame

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 set

- Supply Capability:

- 4100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords