Drop Forged Half Coupler for Scaffolding Q235 Q345 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Drop Forged Half Coupler for Scaffolding

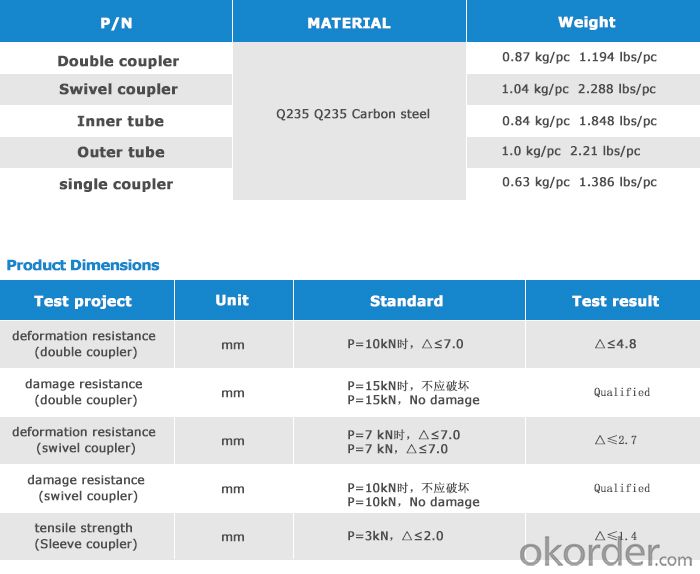

Material :Q235 carbon steel

Production Standard :BS1139 EN74

Applications :Construction

Package :In bag and pallet

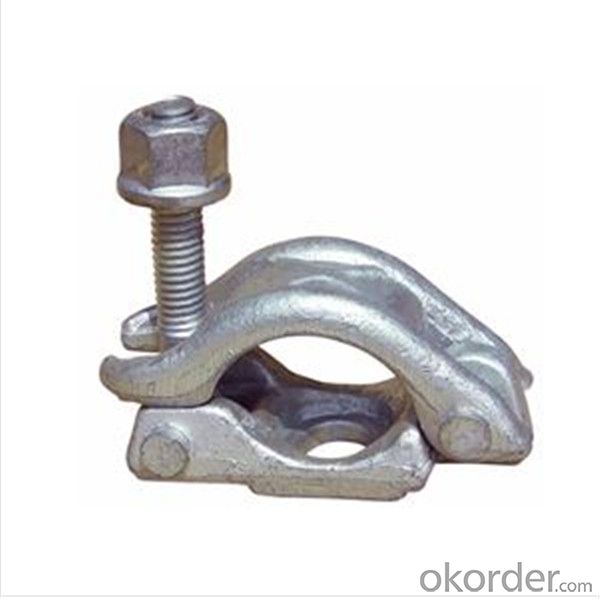

Futures of Drop Forged Half Coupler for Scaffolding

Our forged couplers are with superior abrasive resistance/ deformation resistance/anti-fatigue capacity/anti break capacity/ tensile property.

Especially adapting the 8.8 grade high strength screw & surface galvanized de-rusting process, the forged scaffolding couplers greatly reinforced the firmness & deformation resistance & corrosion resistance.

Our scaffolding couplers contributed to keep the scaffolding system reliability and safety and hardly cause the slippage accidents.

All galvanized scaffolding couplers with anti-rust processing are designed for a longer lifespan and strictly manufactured according to National standards.

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: I would like a scaffold piercing, but my parents aren't going to let me have two cartilage piercings at once. So, can they be done separately, as in weeks apart?

- Technically yes but it is better to have them done at the same time so the holes are aligned properly. It is better to get them done at the same time, as the second piercing will be less painful because you are all adrenalin-ed up! Probably cheaper too.

- Q: Key points for safety of portal scaffolding

- 2, take off the scaffolding workers must wear a helmet, wearing a seat belt, wear non slip shoes.3, the construction load should meet the design requirements, shall not overload; shall not be stacked on the scaffolding template, steel and other objects. Prohibited in the scaffolding on the pull cable wind rope or fixed, erection of concrete pump, pump and lifting equipment etc..

- Q: Im hoping to get an industrial/scaffold piercing done at the very beginning of the summer holidays.Is it possible that they can be pierced with 2 separate pieces of jewellery rather than one bar.Also would it be healed in time to take it out once the holidays are over (6 weeks)??Please help??!?Thanks x

- Yep, some piercers prefer to do it that way. Just make sure you let them know that that's what you want when you go into the shop and they can accommodate you. No cartilage piercing is healed enough to remove in 6 weeks. Cartilage piercings can take anywhere from 6-12 MONTHS to fully heal.

- Q: I plan to have a scaffolding or industrial piercing soon, but don't know where to go.Any suggestions and could you include the prices?x

- Cost depends on the studio. It ranges from 20 to 45 pounds for each piercing, most common price is 25 pounds for each piercing, high quality titanium or stainless steel jewelry included. The industrial is 2 piercings in one so : 25 + 25 = 50 pounds, jewelry included.

- Q: What are the main safety problems when dismantling the scaffold

- 5, all construction materials must be set according to the material classification management requirements must be neatly stacked, "work finished, as material, the site is clean before work".6, on-site construction waste in a timely manner to clean up and deal with the designated place.7, scaffolding workers must be trained and qualified, safety examination, hold certificate to posts jiazigong.

- Q: Im thinking of getting a scaffold piercing when i am old enough to and ive seen videos of people who have one but it cause bacteria in their ear and if they take it out their ears swell. I want to know if this is a bad piercing to get. Also i have had an allergic reaction to an earring before and im not sure what type of earring it was. Can that affect it as well.

- It shouldn't be dangerous if you go to a good piercer (mine pierced mine funny) and clean it regularly. and it should be fine, Just learn which type of earring you;re allergic to and make sure they dont pierce it with that kind of metal.

- Q: What are the common rules for calculating the amount of scaffolding works

- According to the wall masonry scaffolding (single) vertical projection area calculation with square metre.Scaffolding, without deduction of door and window opening, air ring, vehicle channel, deformation joint area. At the same time, the height of the same building is different, according to the vertical height of the building.

- Q: So, 12 Days Ago I Went To Blue Banana To Get Scaffolding On My Right Ear. Everything Went Fine And They Did A Brilliant Job. I Clean It With Sea Salt Soaks 2-3 Times A Day And Use A Bit Of Tea Tree Oil After To Help Sooth. I Was Just Wondering From People Who've Experienced This Piercing How Long It Took For Yours To Stop Hurting And The Time It Took For The Swelling To Go Down (: Thank You lt;3

- It only really hurt for the first month-ish but was really tender for the first 3 months. After that, I barely noticed it was there. Goodluck :]

- Q: Can anybody provide me the formula for calculating scaffold volume on circular tank?

- Step 1. Measure the diameter of the tank (D). Step 2. Measure the height (h) for a vertical tank or length (l) of a horizontal tank. Step 3. Calculate the cross-sectional area of the tank using Equation 1. Equation 1: Cross-sectional Area, A = 3.14 x D x D/4 Step 4. Calculate the volume of the tank in cubic feet using Equation 2. Equation 2: Volume in cubic feet = A x h [for a vertical tank] Volume in cubic feet = A x l [for a horizontal tank] Step 5. Convert the volume of the tank from cubic feet to gallons using Equation 3. Equation 3: Volume in gallons = (Volume in cubic feet) x 7.48

- Q: So im a guyAnd I might get oneAnyone had one before/got one?Any advice?How much do they normaly cost?if you answer this i will love you forever :)

- okay, if you do end up getting it, make sure you get it on the side you DONT sleep on. dont let shampoo get on it. be really careful with it. if you have longer hair dont let your hair get caught in it cause it'll get tangled on it and it'll hurt and tug on the bar. it's usually around 40 dollars for it. this piercing requires a long time to heal and it has a high risk of infection. but if you take good care of it, you'll be good (: hope this helpedd.

Send your message to us

Drop Forged Half Coupler for Scaffolding Q235 Q345 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords