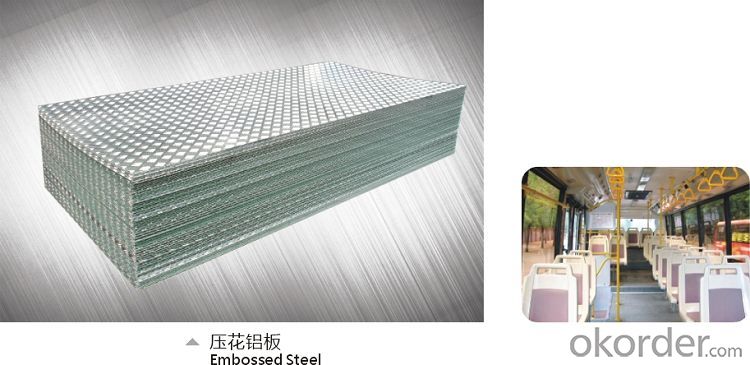

Dollar Tree Aluminum Foil Sheets - Aluminum Figured Sheet for Various Uses

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

Aluminium foil acts as a total barrier to light and oxygen (which cause fats to oxidise or become rancid), odours and flavours, moistness, and germs, it is used broadly in food and pharmaceutical packaging. The purpose of aluminium is to make long-life packs (aseptic processing|aseptic packaging) for drinks and dairy goods, which allows storing without refrigeration. Aluminium foil containers and trays are used to bake pies and to pack takeaway meals, ready snacks and long life pet foods.

Aluminium foil is widely sold into the consumer market, often in rolls of 500 mm (20 in) width and several metres in length.It is used for wrapping food in order to preserve it, for example, when storing leftover food in a refrigerator (where it serves the additional purpose of preventing odour exchange), when taking sandwiches on a journey, or when selling some kinds of take-away or fast food. Tex-Mex restaurants in the United States, for example, typically provide take-away burritos wrapped in aluminium foil.

Aluminium foils thicker than 25 μm (1 mil) are impermeable to oxygen and water. Foils thinner than this become slightly permeable due to minute pinholes caused by the production process.

- Q: What is an aluminium plate? What is the difference between carbon steel sheet, galvanized sheet and stainless steel plate?What is the order of the price? Thank you

- Aluminized sheet, the full name of aluminum plating, also known as aluminized steel plate, also known as hot dipped aluminum plate.Aluminized steel plate is an aluminum silicon alloy coating steel plate, in which the aluminum content is 90%, silicon 10%. The aluminized steel plate has good heat resistance, heat reflection and corrosion resistance. Its mechanical and physical properties are better than those of cold-rolled steel sheet. Because of the superior performance of aluminized steel sheet, it has been widely used in our daily necessities. Such as car muffler, household appliances and so on.

- Q: Explain the similarities and differences in the properties of aluminum metal, Al(s) and aluminum oxide (a salt) Al203(s) in terms of the particles and forces present.. thanks doods!

- Aluminum metal is not found in nature, only aluminum oxide is in the mine or ground and they have to separate it from the oxidation to make a useful metal.

- Q: How does the thickness tolerance of aluminum sheet affect its usability?

- The thickness tolerance of aluminum sheet plays a significant role in its usability. A narrow thickness tolerance ensures uniformity and precision in the sheet's dimensions, allowing for consistent performance and ease of fabrication. It enables seamless integration into various applications, including construction, automotive, aerospace, and manufacturing industries. On the other hand, a wider thickness tolerance can limit its usability as it may result in irregularities, difficulty in fitting, and potential performance issues. Therefore, a tight thickness tolerance is crucial for ensuring optimal functionality and versatility of aluminum sheets.

- Q: What are the different grades of aluminum sheets?

- There are several different grades of aluminum sheets available in the market, each with its own unique properties and uses. The most commonly used grades include 3003, 5052, and 6061. - Grade 3003: This is a non-heat treatable alloy that is highly resistant to corrosion. It is often used in applications where corrosion resistance is essential, such as in packaging, cooking utensils, and chemical equipment. - Grade 5052: This grade is also non-heat treatable and offers excellent corrosion resistance. It is known for its strength and durability, making it suitable for marine applications, transportation equipment, and architectural purposes. - Grade 6061: This is a heat treatable alloy that combines good corrosion resistance with high strength. It is widely used in structural applications, such as in aircraft components, automotive parts, and construction materials. Apart from these grades, there are also other specialized aluminum alloys available, such as 2024, 7075, and 5083, which offer specific properties for particular industries or applications. It is important to consider the specific requirements of your project before choosing a grade of aluminum sheet, as each grade has its own strengths and limitations. Consulting with a knowledgeable supplier or expert can help you determine the most suitable grade for your needs.

- Q: Are the aluminum sheets suitable for manufacturing aircraft interiors?

- Yes, aluminum sheets are highly suitable for manufacturing aircraft interiors. Aluminum is a lightweight, yet strong and durable material, making it ideal for aerospace applications. Its high strength-to-weight ratio allows for the construction of lightweight and fuel-efficient aircraft. Aluminum sheets are also highly corrosion-resistant, which is crucial in the aerospace industry where aircraft interiors are exposed to various environmental factors such as humidity and temperature changes. This corrosion resistance ensures the longevity and reliability of the aircraft interior components, reducing maintenance and replacement costs. Furthermore, aluminum sheets can be easily fabricated and formed into various shapes, allowing for the production of complex and customized aircraft interior components. They can be easily cut, bent, and welded, offering design flexibility and enabling manufacturers to create sleek and aesthetically pleasing interior designs. In addition to these technical advantages, aluminum is also a sustainable material. It is 100% recyclable, making it an environmentally friendly choice for aircraft interiors. The recycling process requires significantly less energy compared to primary aluminum production, reducing the carbon footprint associated with manufacturing. Overall, the combination of its lightweight properties, corrosion resistance, ease of fabrication, and sustainability make aluminum sheets highly suitable for manufacturing aircraft interiors.

- Q: I'd like to have the aluminum on the etching front white. Do any of the experts know that?

- After anodizing, it turns white. If not, the aluminum plate should be white and spray polyester or fluorocarbon paint,

- Q: What is the weight per square foot of 101 aluminum sheets?

- The weight per square foot of 101 aluminum sheets varies depending on the thickness of the sheets. Please provide the thickness of the aluminum sheets to determine the weight per square foot accurately.

- Q: Where else besides deodorant can we find aluminum?

- it okorder

- Q: What are the mechanical properties of aluminum sheets?

- Aluminum sheets possess several unique mechanical properties that make them highly desirable in various industries. Firstly, aluminum sheets have excellent strength-to-weight ratio, meaning they are lightweight yet offer exceptional strength. This property makes them ideal for applications where weight reduction is crucial, such as aerospace and automotive industries. Moreover, aluminum sheets exhibit good formability, allowing them to be easily shaped and formed into different sizes and configurations. This property makes them highly versatile and suitable for applications requiring complex shapes, such as manufacturing of cans, appliances, and architectural components. Additionally, aluminum sheets have high corrosion resistance due to the formation of a thin, protective oxide layer on their surface. This property makes them highly durable and long-lasting, making them suitable for outdoor applications or environments with high moisture or chemical exposure. Furthermore, aluminum sheets have excellent thermal conductivity, allowing them to efficiently transfer heat. This property makes them widely used in heat exchangers, cooling systems, and other applications where efficient heat dissipation is required. Lastly, aluminum sheets have good electrical conductivity, enabling them to conduct electricity effectively. This property makes them suitable for electrical enclosures, conductors, and other electrical applications. In summary, the mechanical properties of aluminum sheets include high strength-to-weight ratio, good formability, high corrosion resistance, excellent thermal conductivity, and good electrical conductivity. These properties make aluminum sheets a preferred choice for a wide range of applications across various industries.

- Q: Are aluminum sheets suitable for chemical storage tanks?

- No, aluminum sheets are not suitable for chemical storage tanks as aluminum is highly reactive and can corrode when in contact with certain chemicals.

Send your message to us

Dollar Tree Aluminum Foil Sheets - Aluminum Figured Sheet for Various Uses

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords